We offer training on PTFE lined piping produced on site

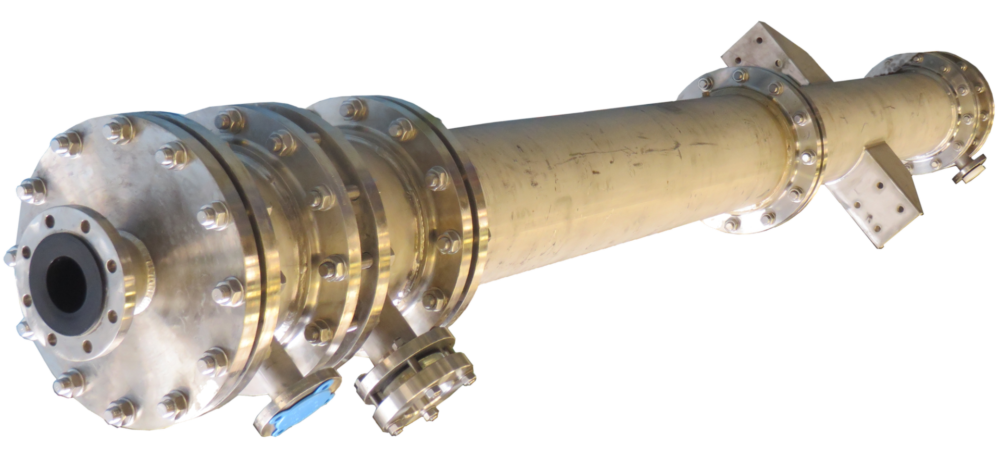

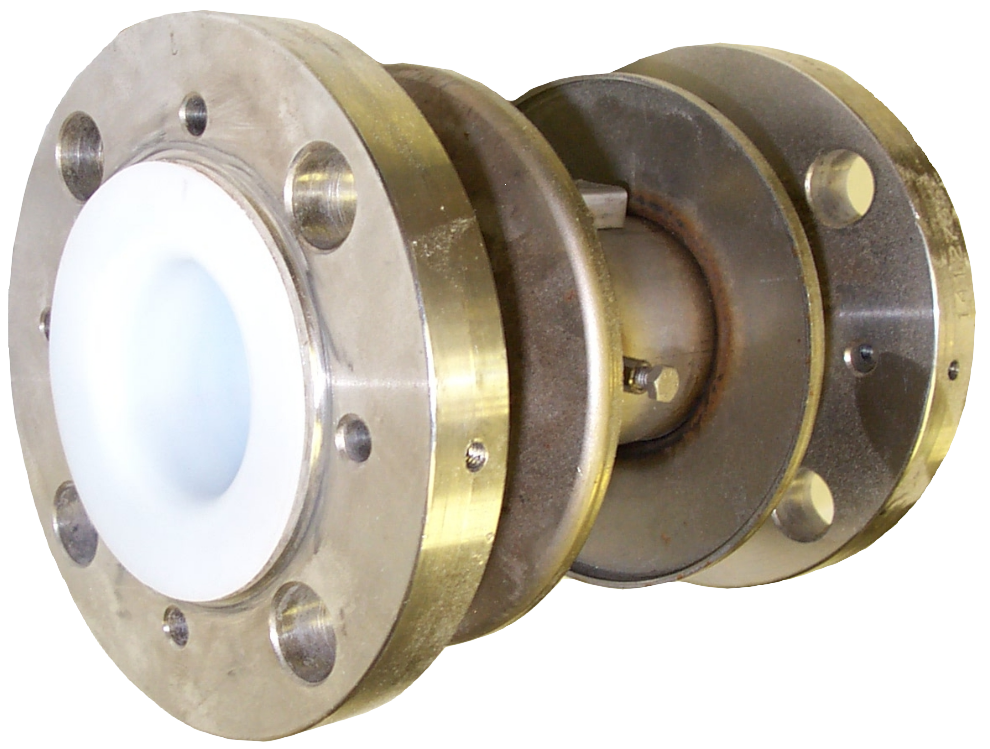

Introduction to Field Flare piping

For any serious user of lined equipment, Field Flare piping is a useful addition. It provides a simple self-help system, enabling the local fabrication of spools for the occasional small modification or maintenance task, or for emergency use.

CRP can support customers who may occasionally manufacture all of their spool requirements locally, due to historic site development or convenience.

Flaring Equipment and Methods

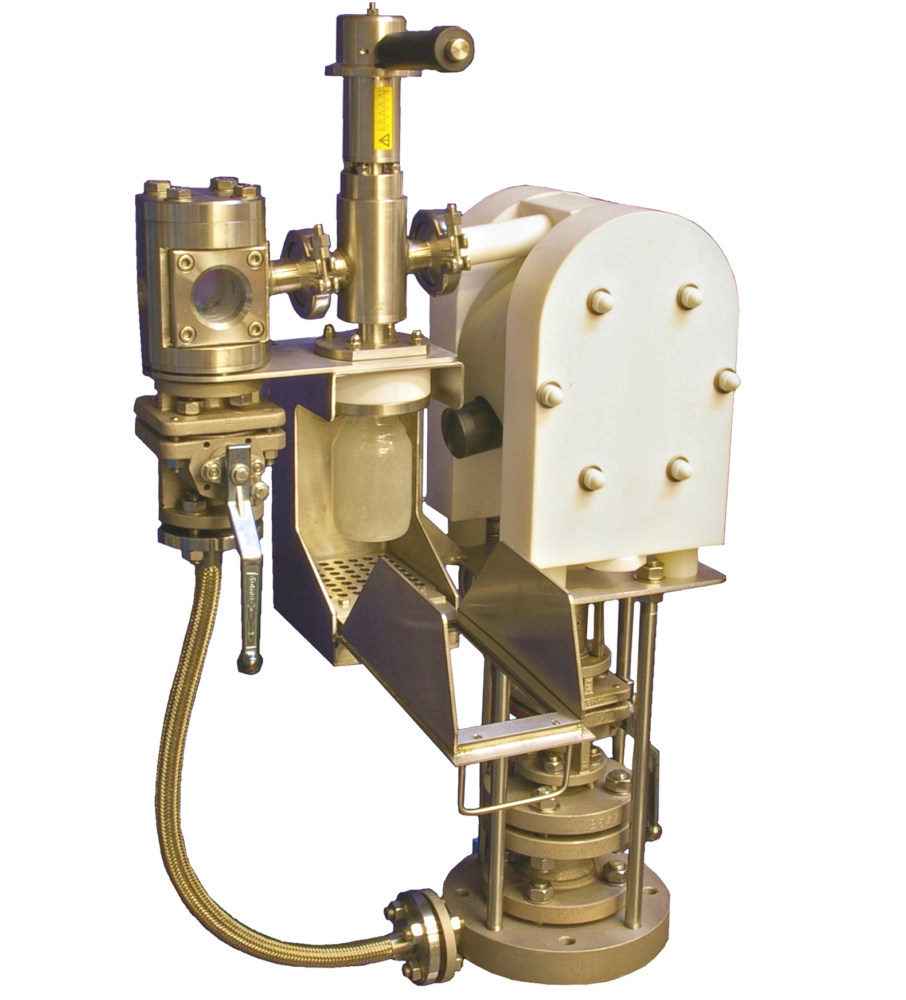

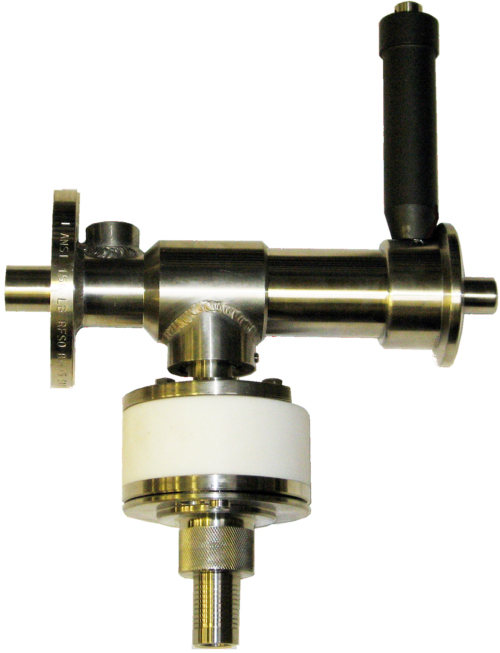

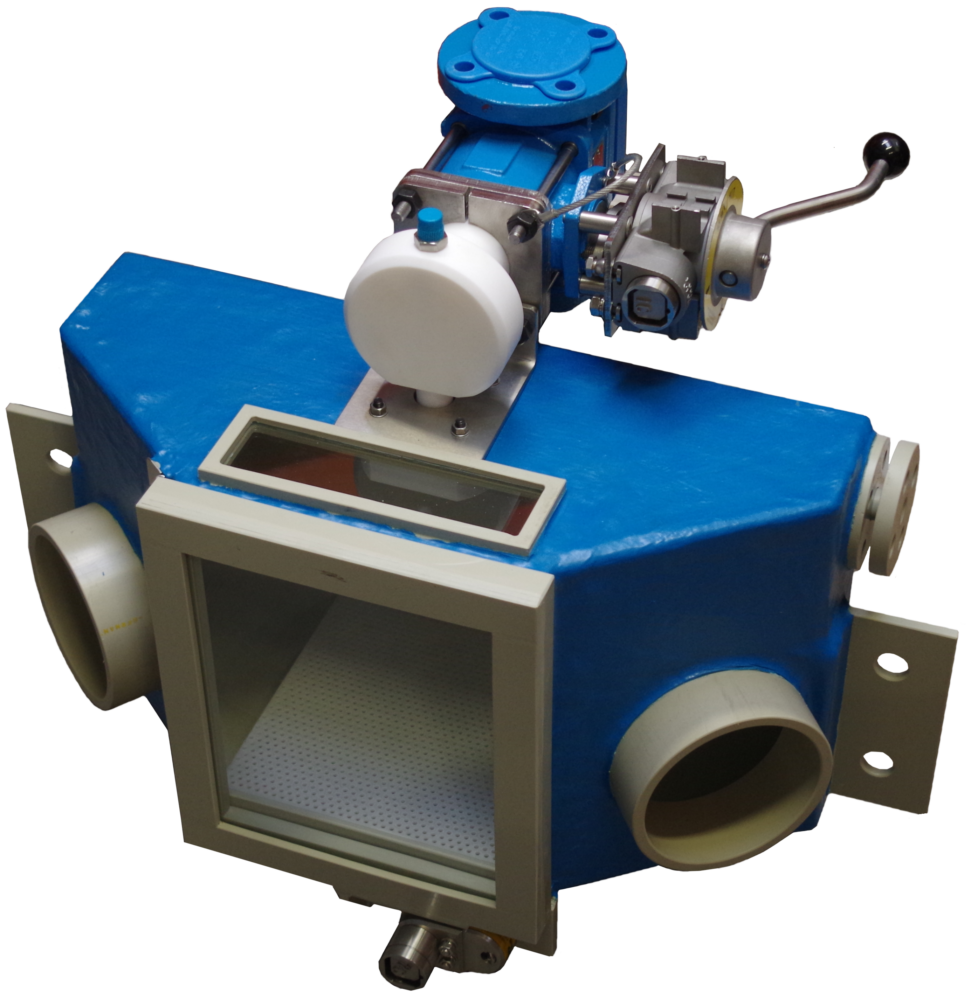

We provide a comprehensive range of field flare materials and manufacturing and installation tooling.

There are essentially two different methods of flaring:

- Using either independently heated tools with an expanding mandrel to support them – Heated Tool Expanding Mandrel Flaring

- Using hot air to heat the PTFE liner and a hub puller to support the tools – Hot Air Hub Pulling Flaring.

The heated tool expanding mandrel flaring is usually used for sliding fit liner systems and hot air hub pulling flaring is usually used for tight fit liner systems, but they can work with both lining systems.

Training Objective

CRP can “approve” nominated staff of the end user or their contractor in the use and installation of field flare spools, through the provision of training.

Training Method

Training is usually provided at CRP’s factory via a practical training session. This enables the candidates not only to undertake hands on training on the activity of field flaring, but also to understand all of the the other issues that surround the use of fluoropolymer lined equipment

Training Syllabus

The standard training syllabus that is covered in the classroom sessions follows the below structure:

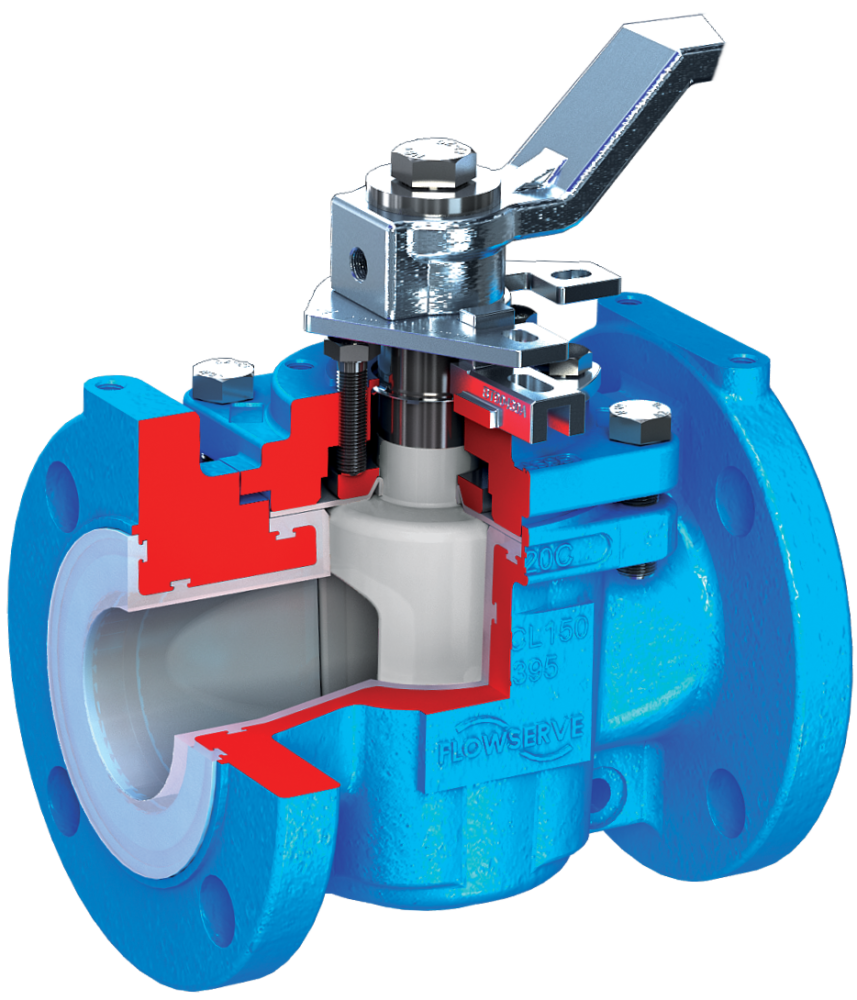

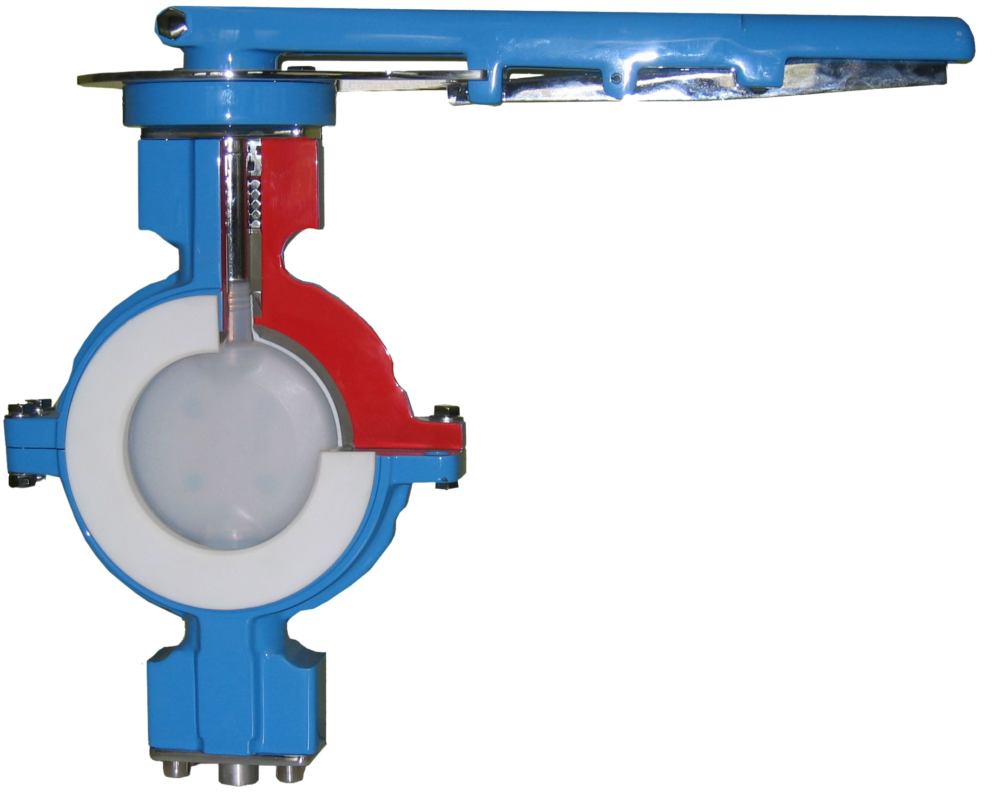

- Overview of PTFE and its characteristics

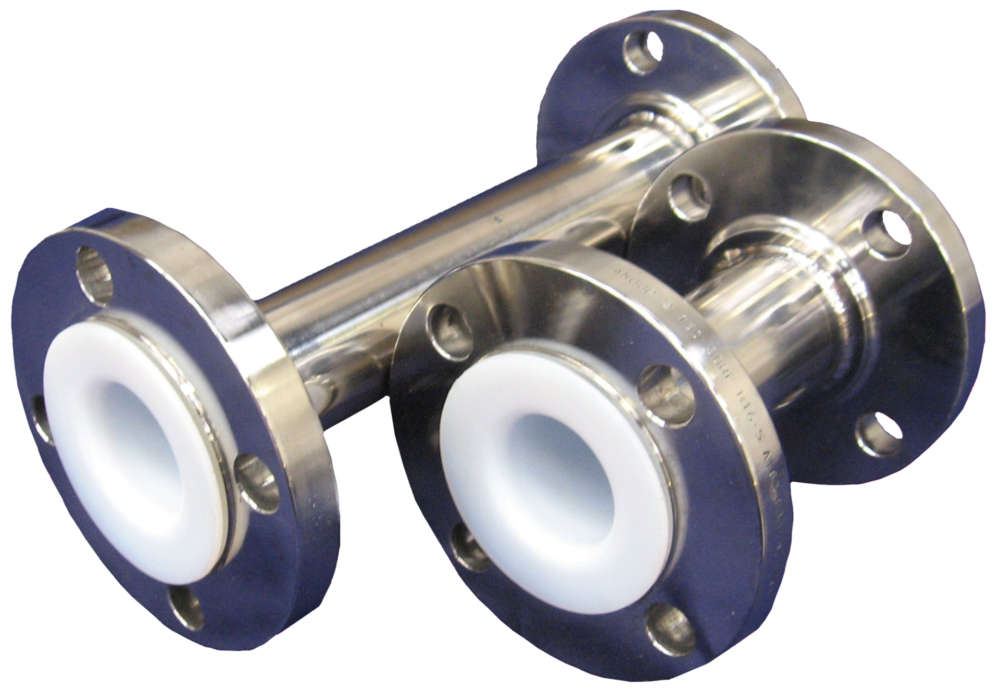

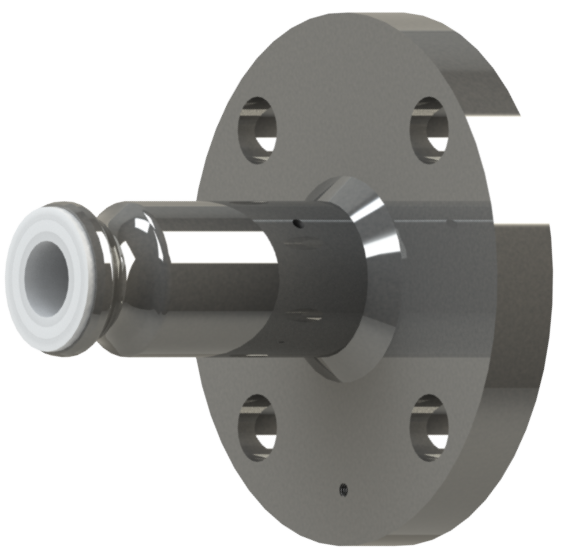

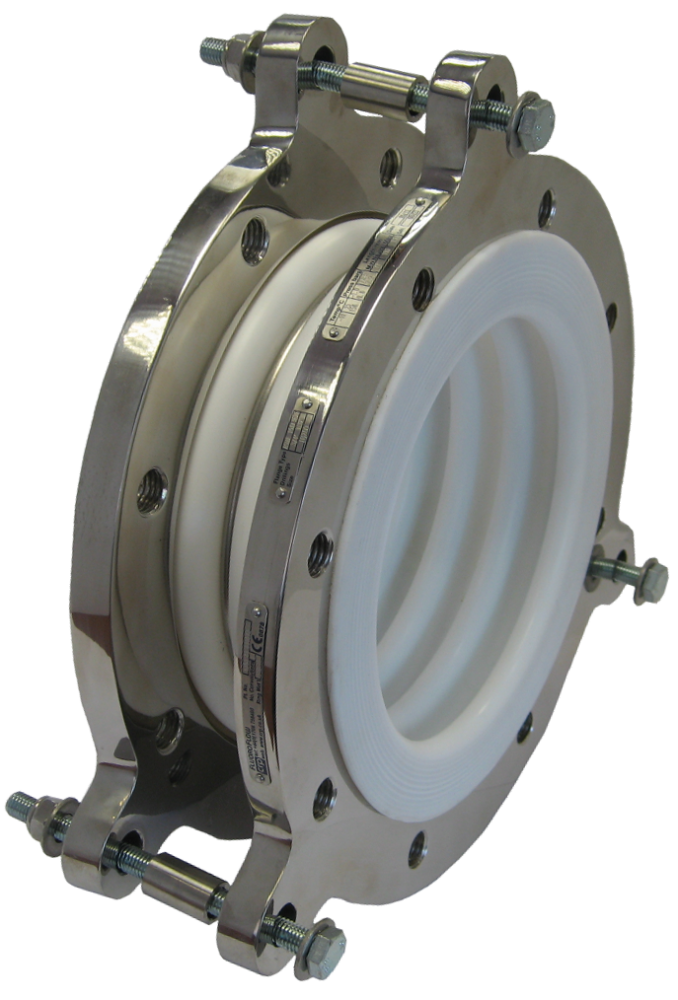

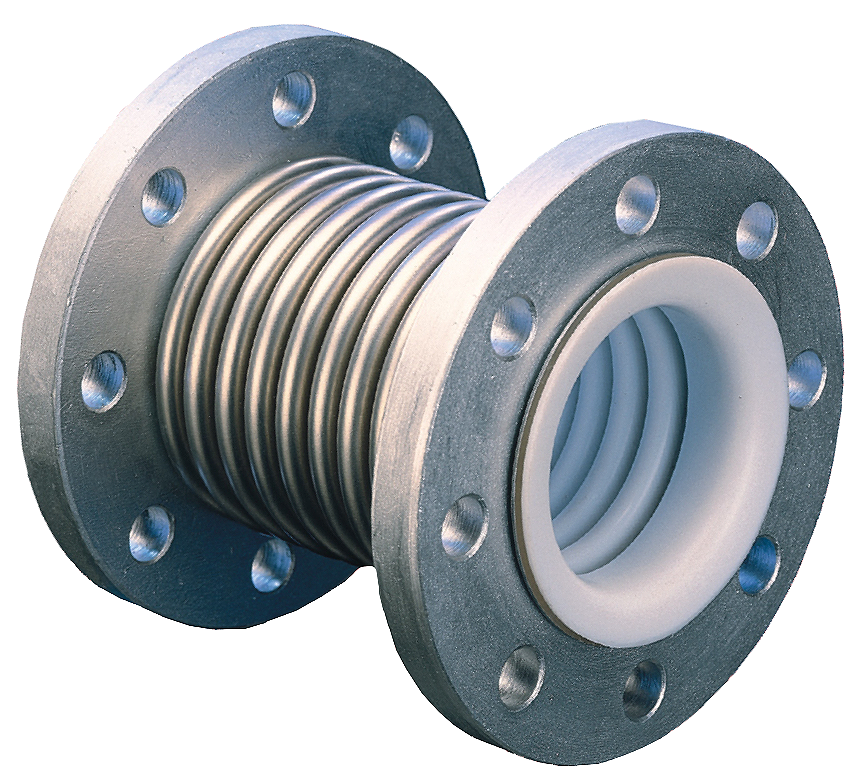

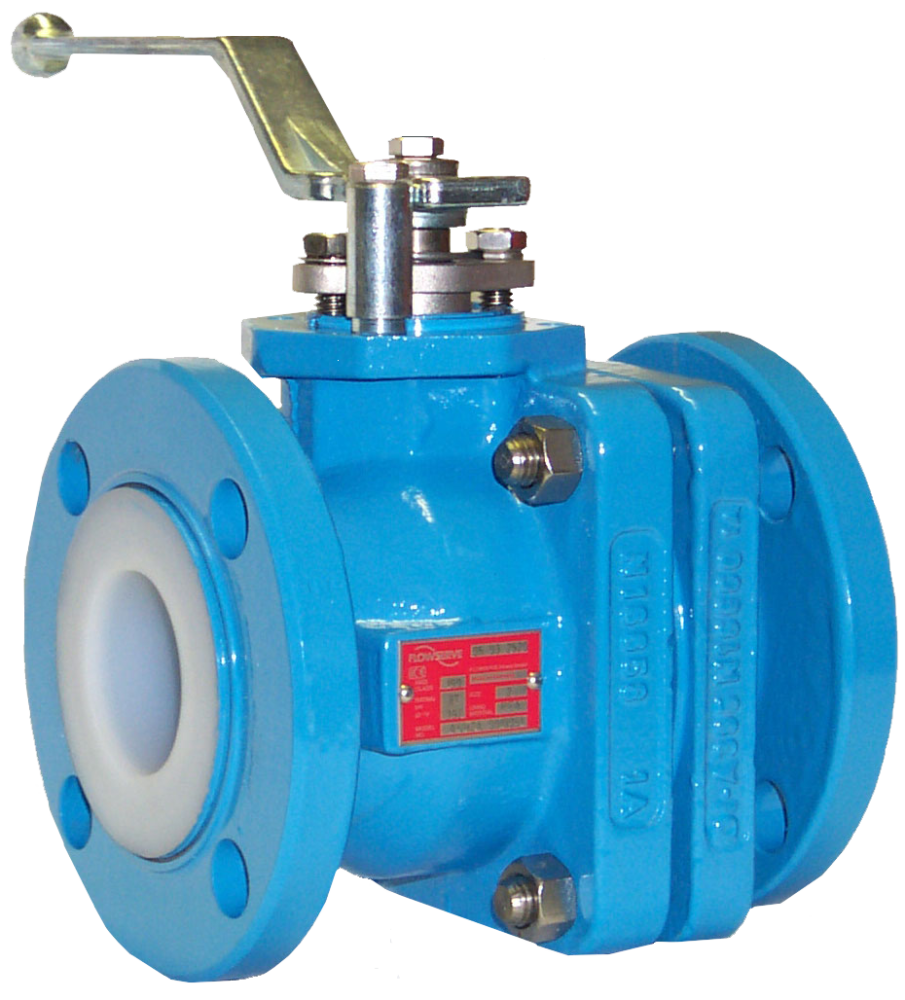

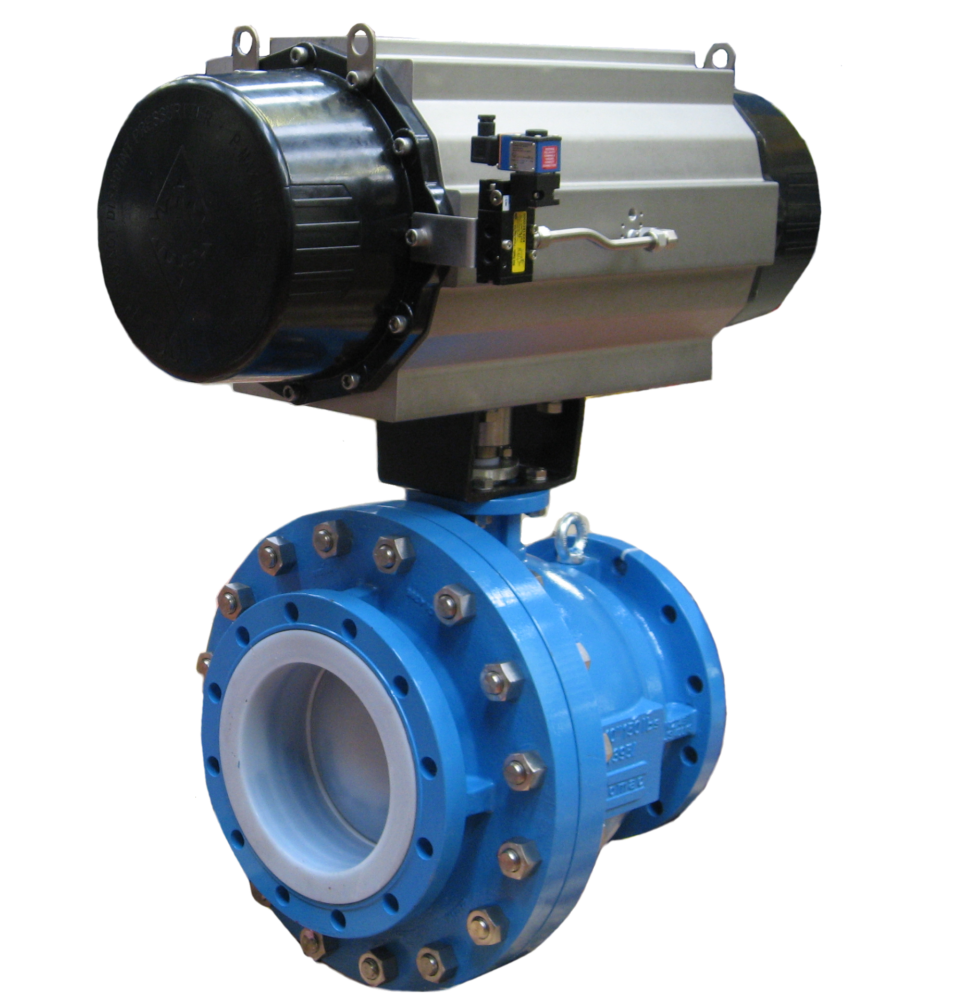

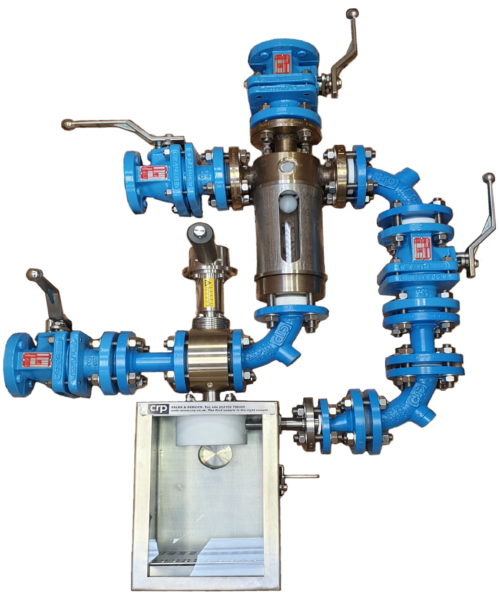

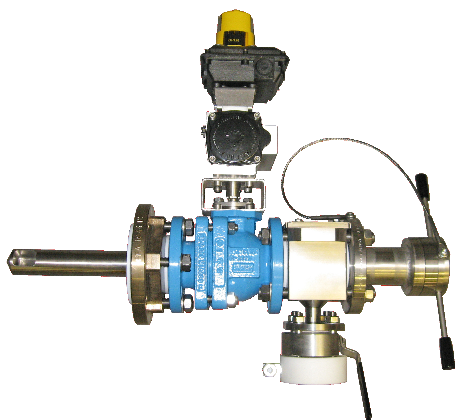

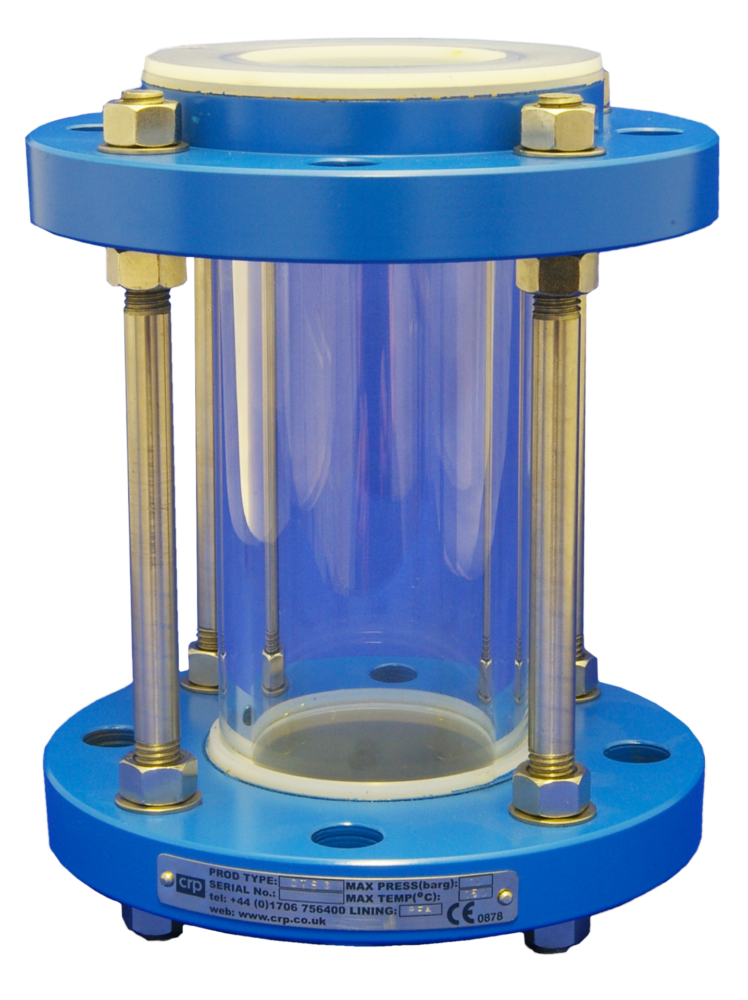

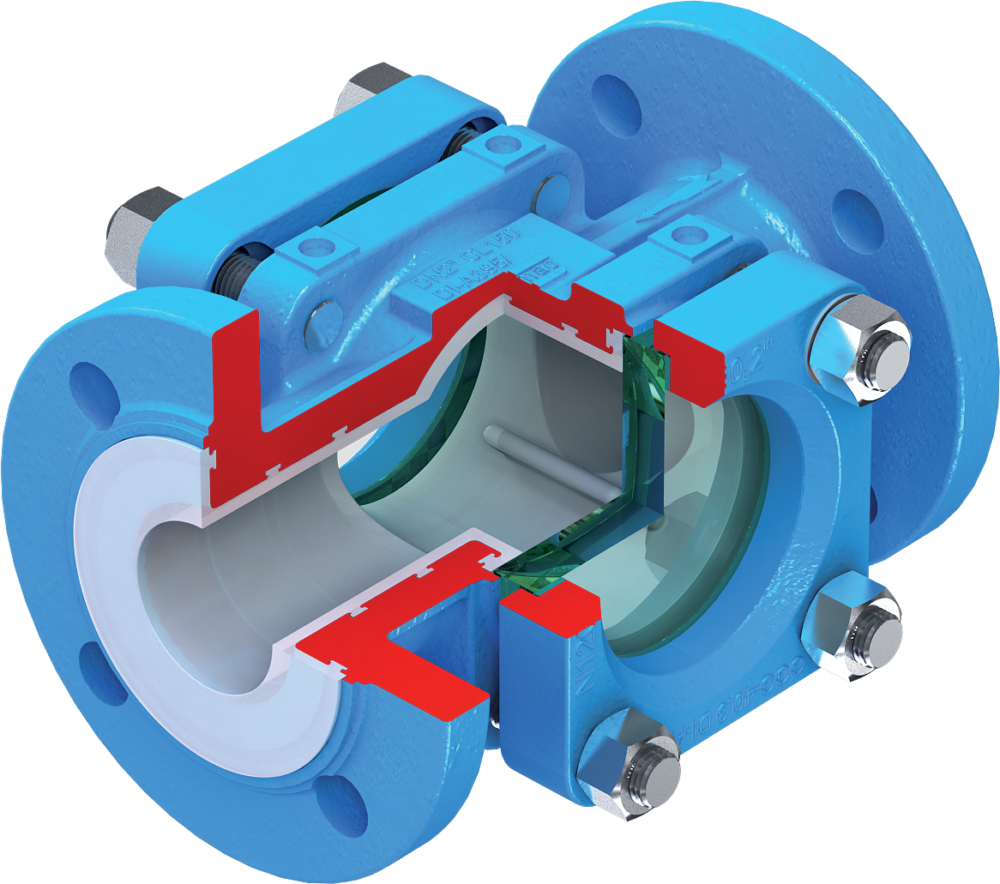

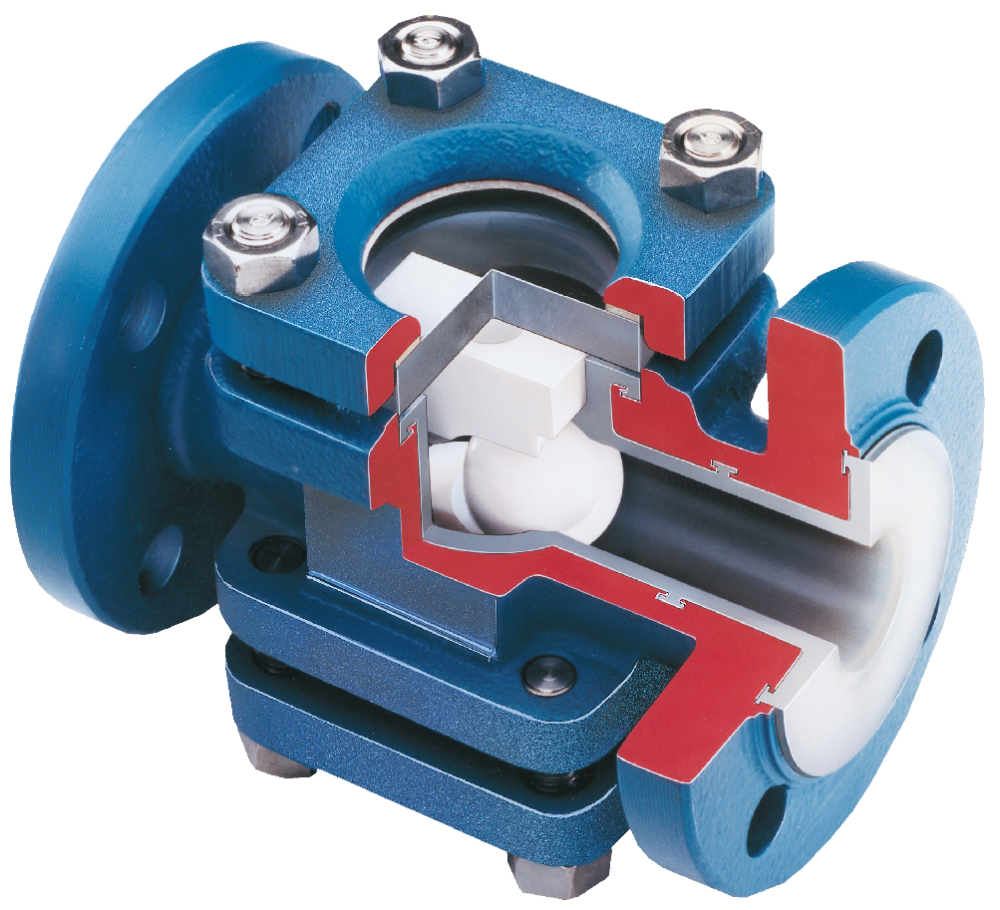

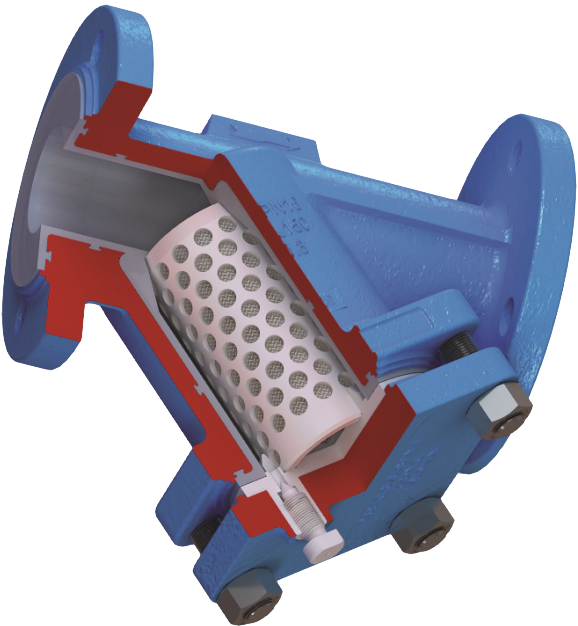

- How lined piping systems work

- When and why to use a field flare system

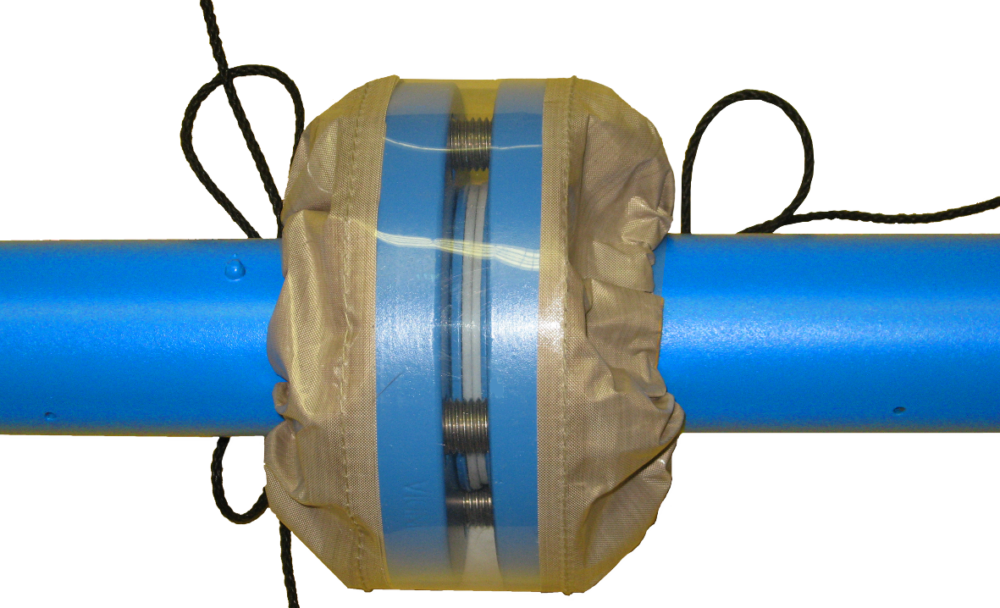

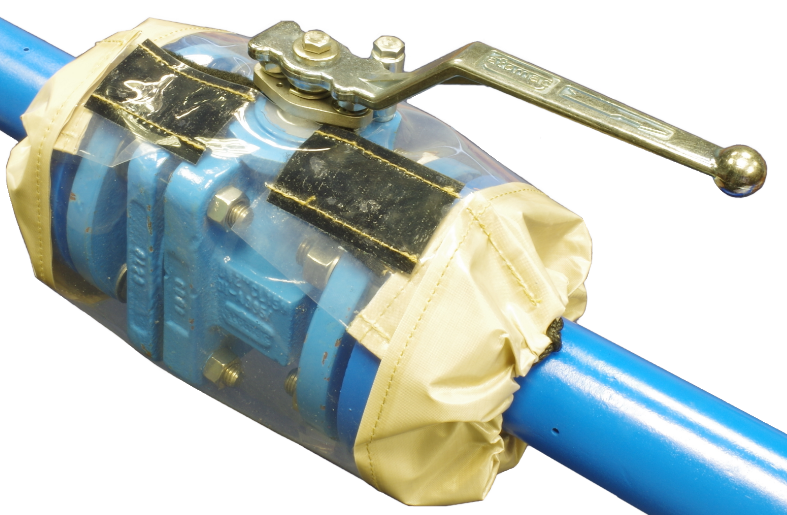

- Venting systems and the reasons why

- Mechanics of field flare

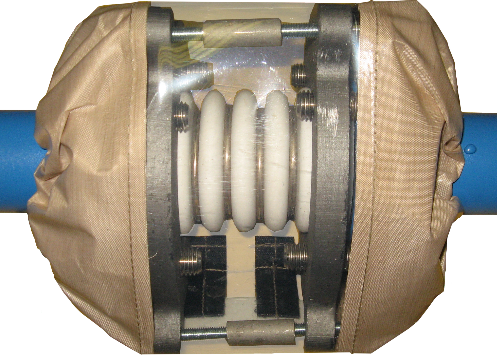

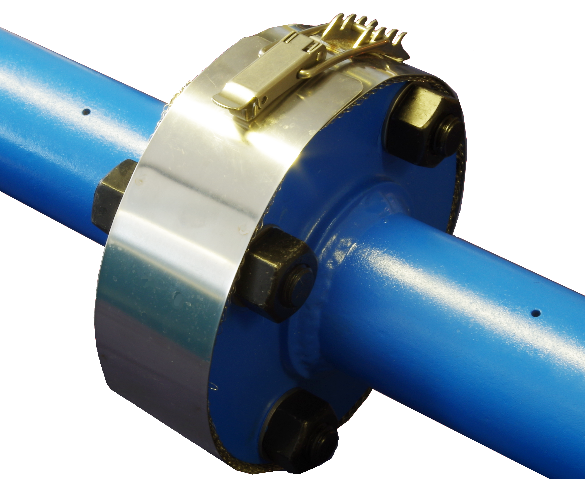

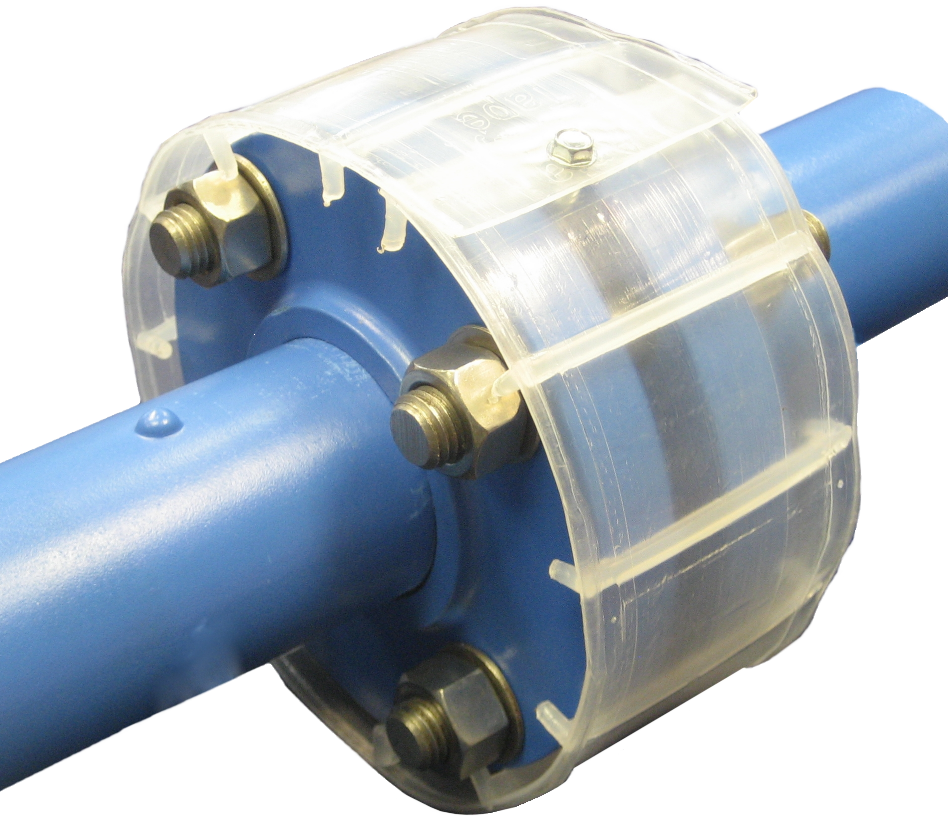

- Varieties of field flare piping

- Varieties of flaring systems

- How it is delivered

Practical training sessions follow the below structure:

- Storage and handling on site.

- The field flare toolkit – its components, care and maintenance.

- Health and Safety personal protective equipment, risks.

- Site Measurement:

- Allowance for liner thickness.

- Steelwork fabrication methods.

- Steelwork preparation, deburring, radiussing, venting.

- Preparation of working area and service requirements.

- Preparing tools.

- Preparing liner.

- The flare.

- Fitting the makeup piece.

- Bolting.

- Inspection.

- Practical.

The above training is mixed with hands-on training. This allows the personnel to undertake field flares and receive practical instruction.

Examination

Examinations are practical and require the trainee to fabricate one end of a field flare spools. CRP provide the materials and tooling, but without instruction or documentation.

After completion or failure, feedback will be given and further instruction will follow if required.

Certification

CRP provides documentation explaining the scope of the training and its completion for each individual. Certification will be forwarded to you for retention or distribution as you see fit.

Course Materials

Course materials are supplied for each attendee. These include notes relating to the presentation and other reference materials for subsequent reference.

Caveat

It is important to note that we are not acting as paid consultants, and we are not insured for such a role. However, we believe that we can bring a wealth of both theoretical and practical experience that is not available from other sources, which should give your team and others a good background in working with these materials. Costs are usually on the basis of meeting our expenses.