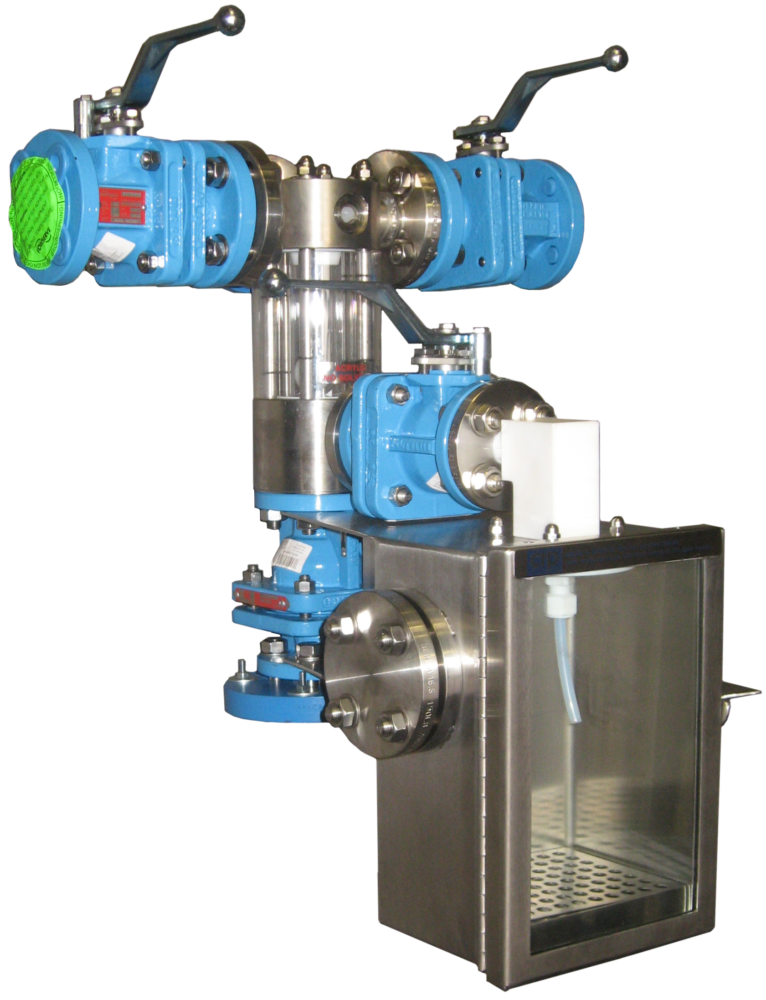

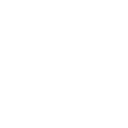

Non-recirculating Vessel Sampler

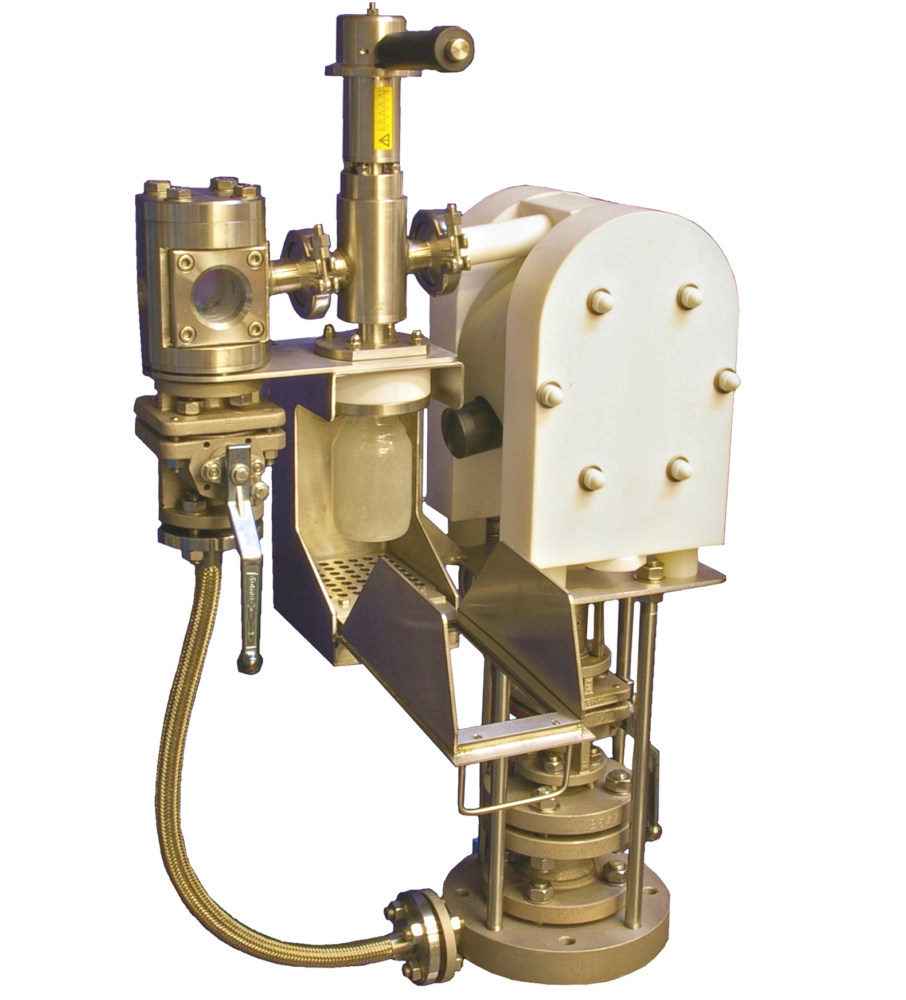

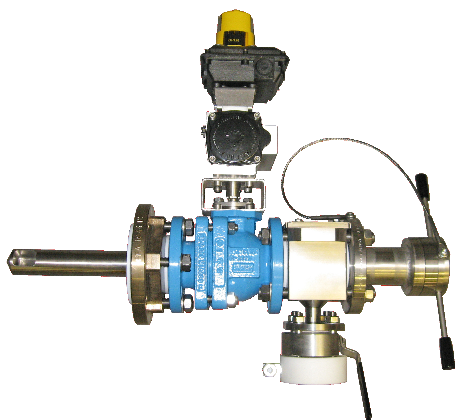

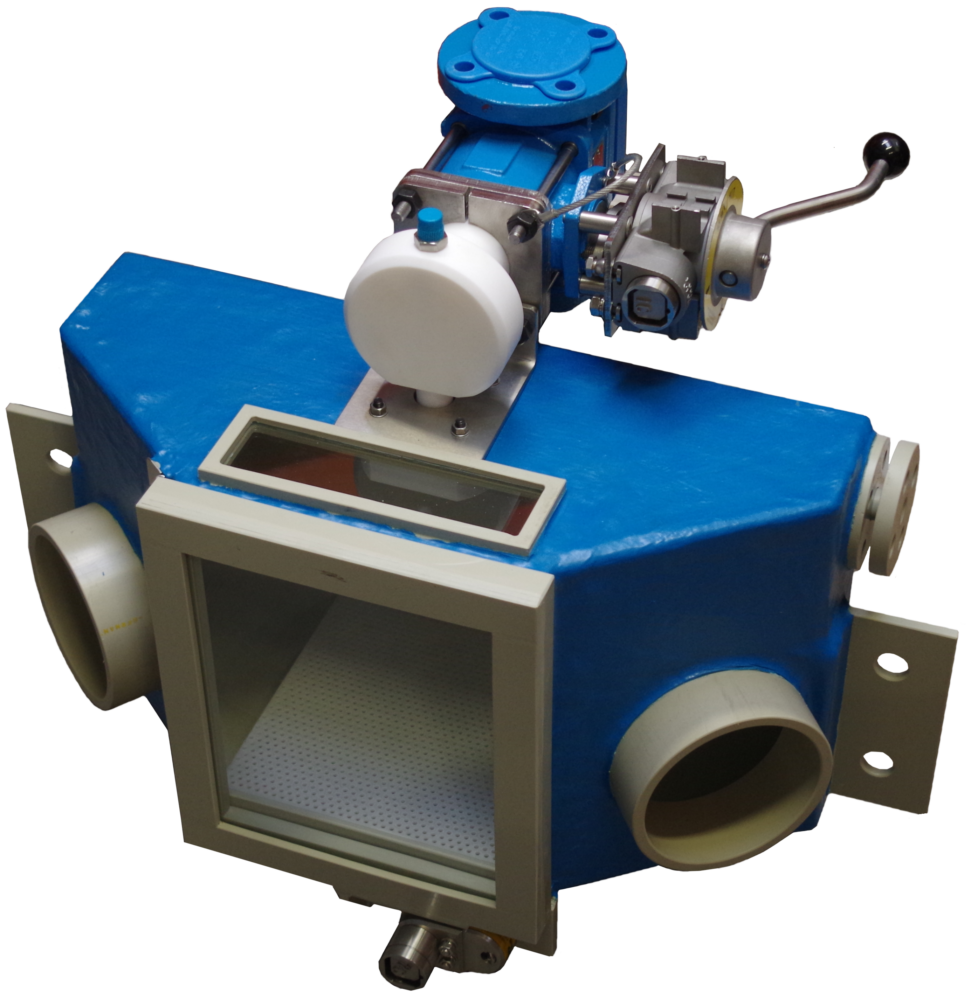

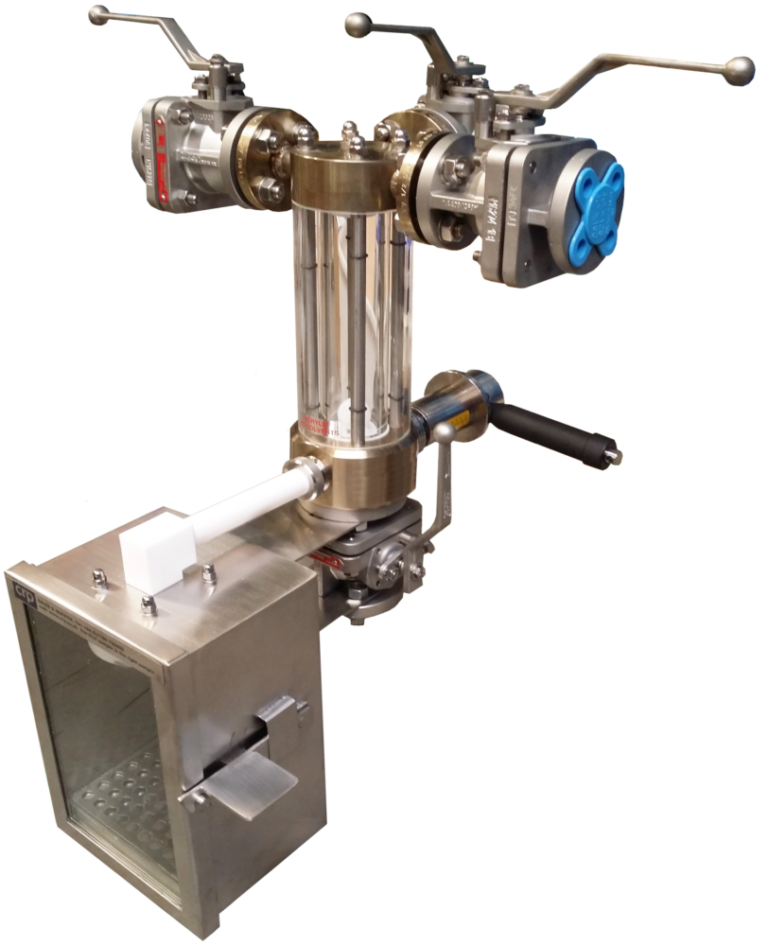

Our vessel mounted sampling systems extract a sample from a vessel through a dip pipe mounted on the lid and capture this in a sight glass, before being dispensed into the sample bottle. The sample either forced up the dip pipe into the sight glass with pressure, if the vessel is pressurised. Alternatively, if it is working at atmospheric pressure or under slight vacuum, then vacuum is used to draw the sample from the vessel.

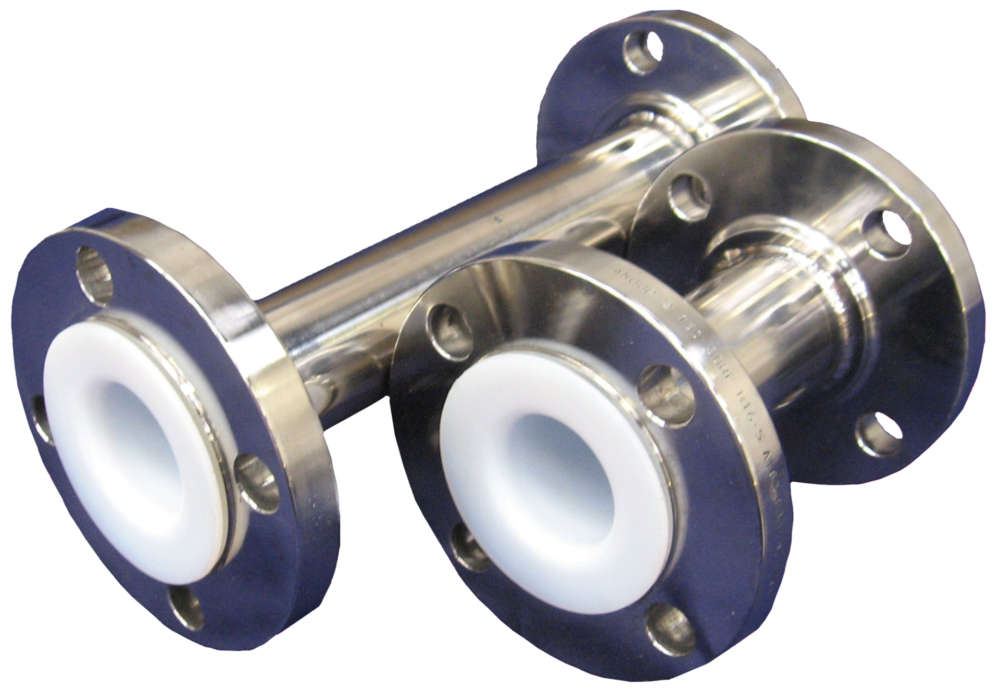

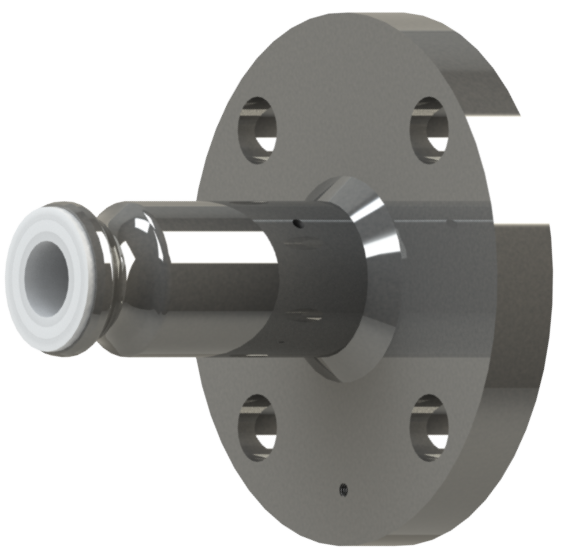

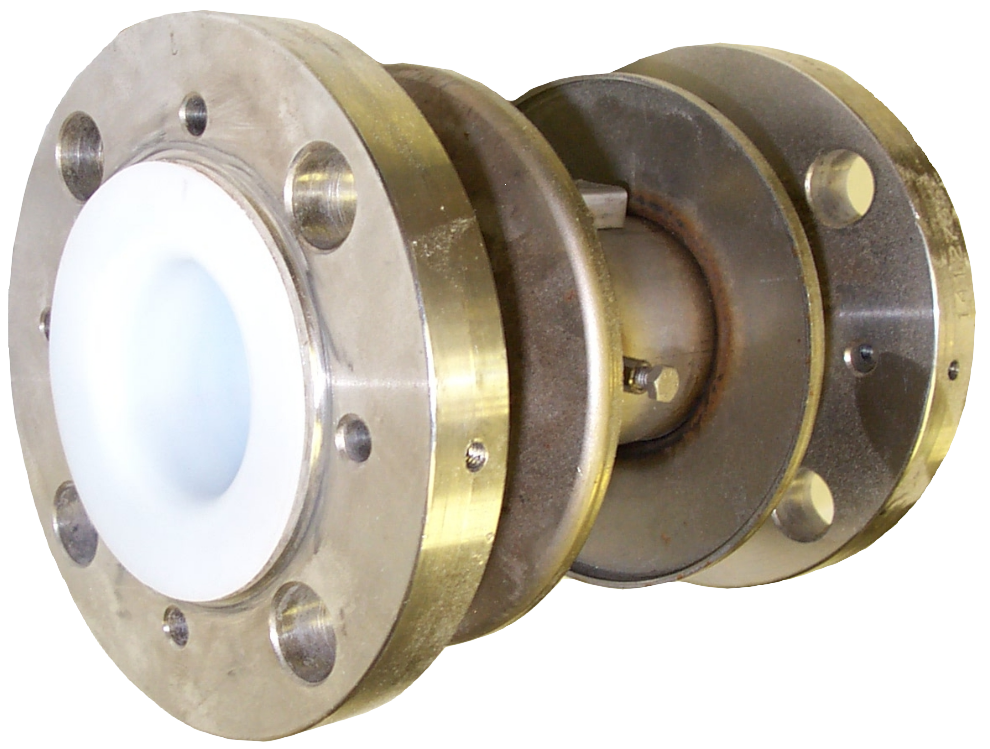

Designed to meet each customer’s requirements, nearly no two vessel samplers are the same. Materials of construction can be stainless steel or PFA / PTFE lined for sampling high corrosive media.

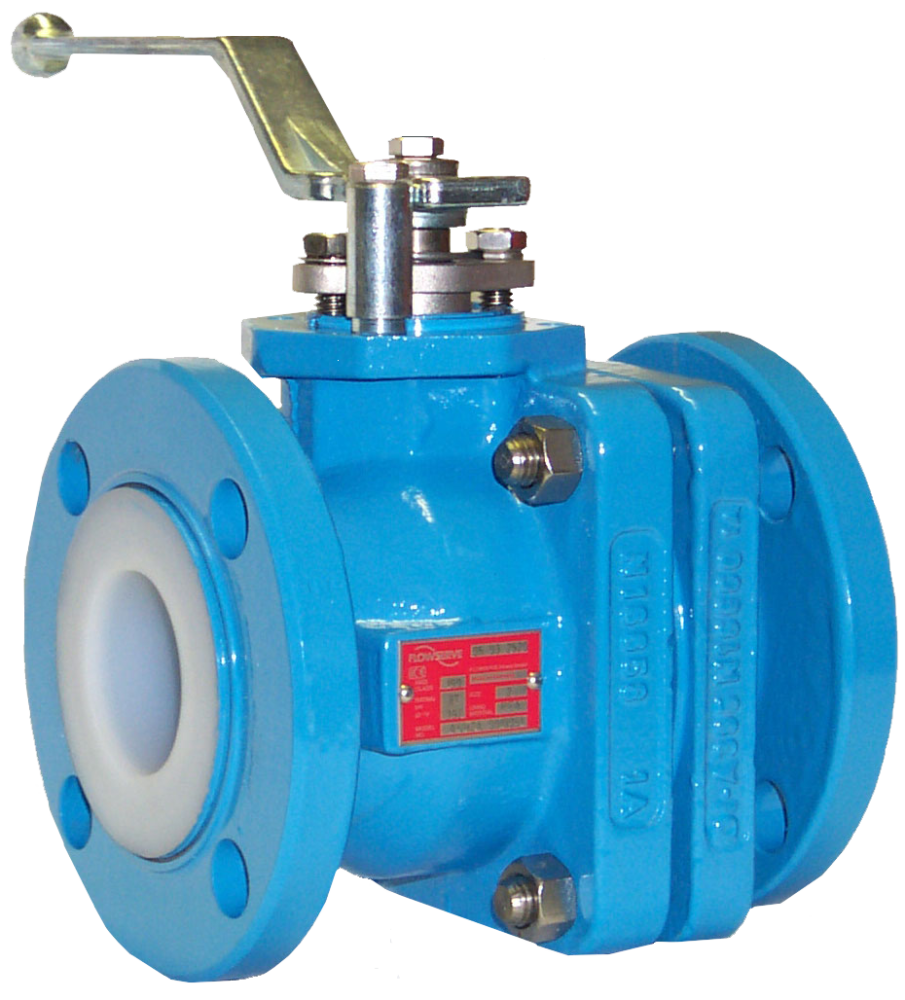

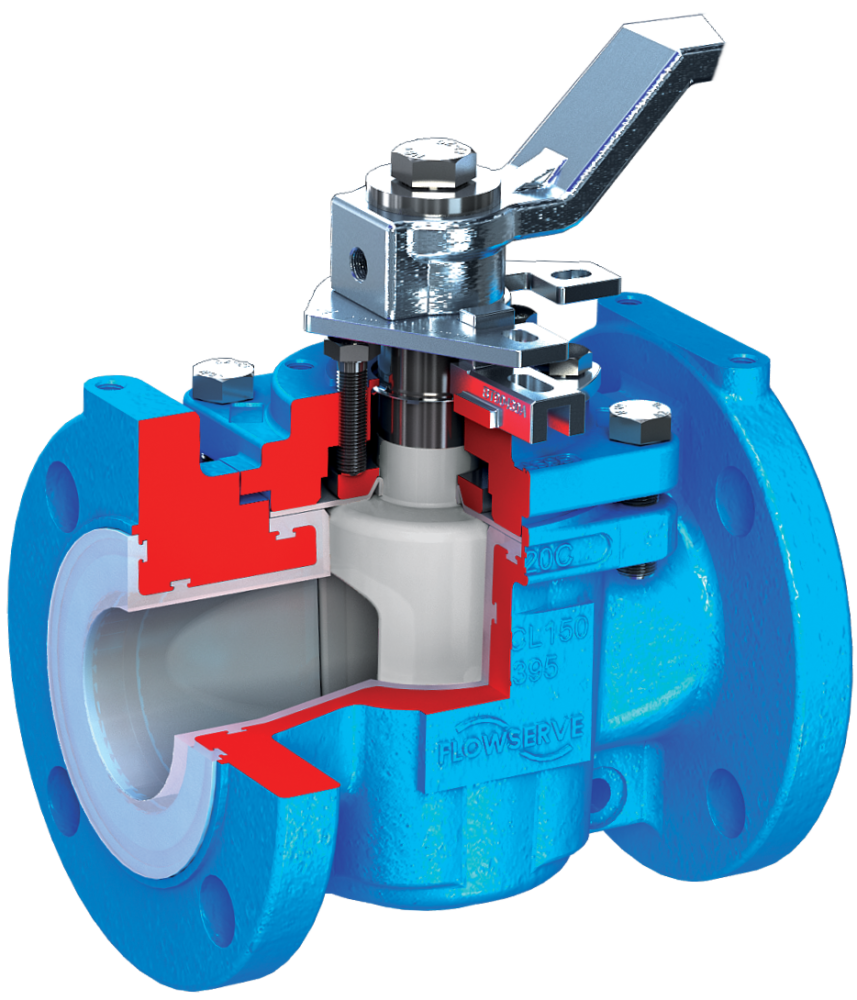

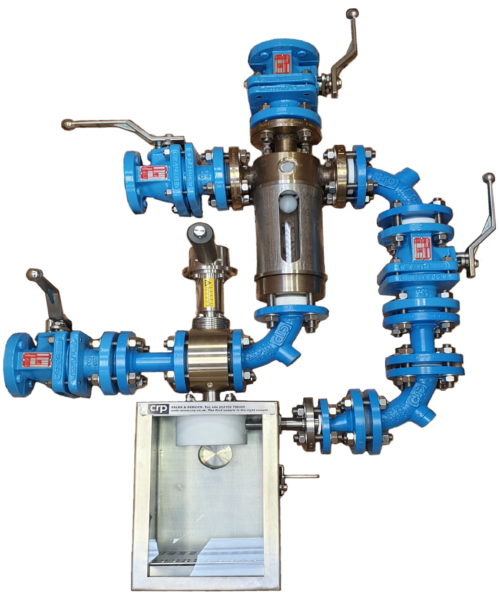

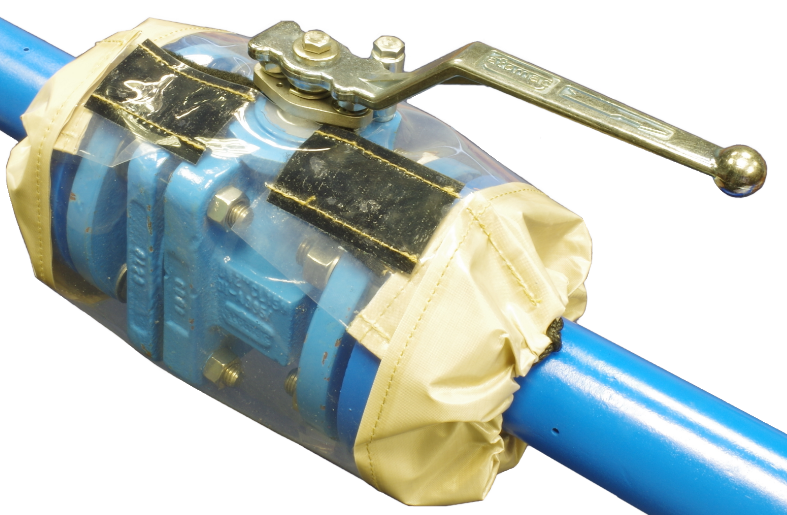

The service valves are connected to the manifold mounted at the top of the sight glass section. These control the vacuum or vent to draw the sample into the sight glass, a compressed gas which is usually nitrogen, to purge the sight glass clear and blow the dip pipe clear into the vessel and sometimes a connection to a wash liquor like a solvent to clean the system of any residue. We can also include another port for a pressure gauge or just for use in the future.

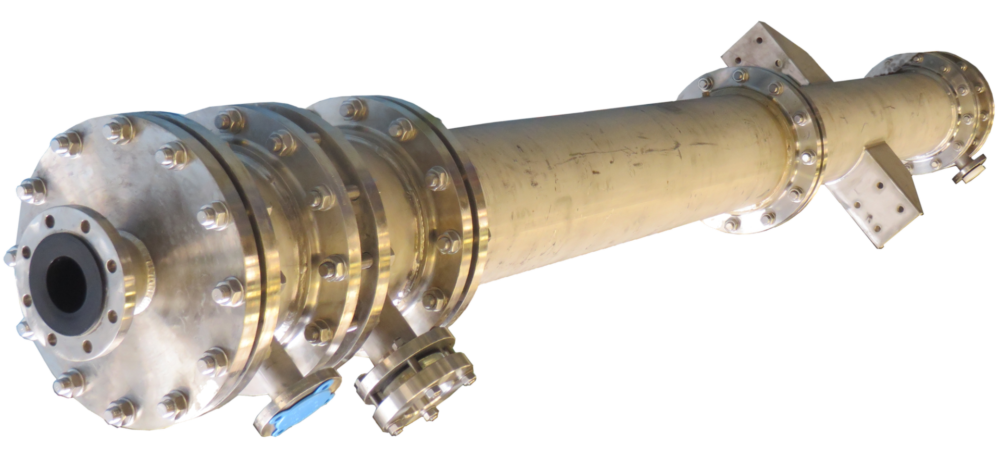

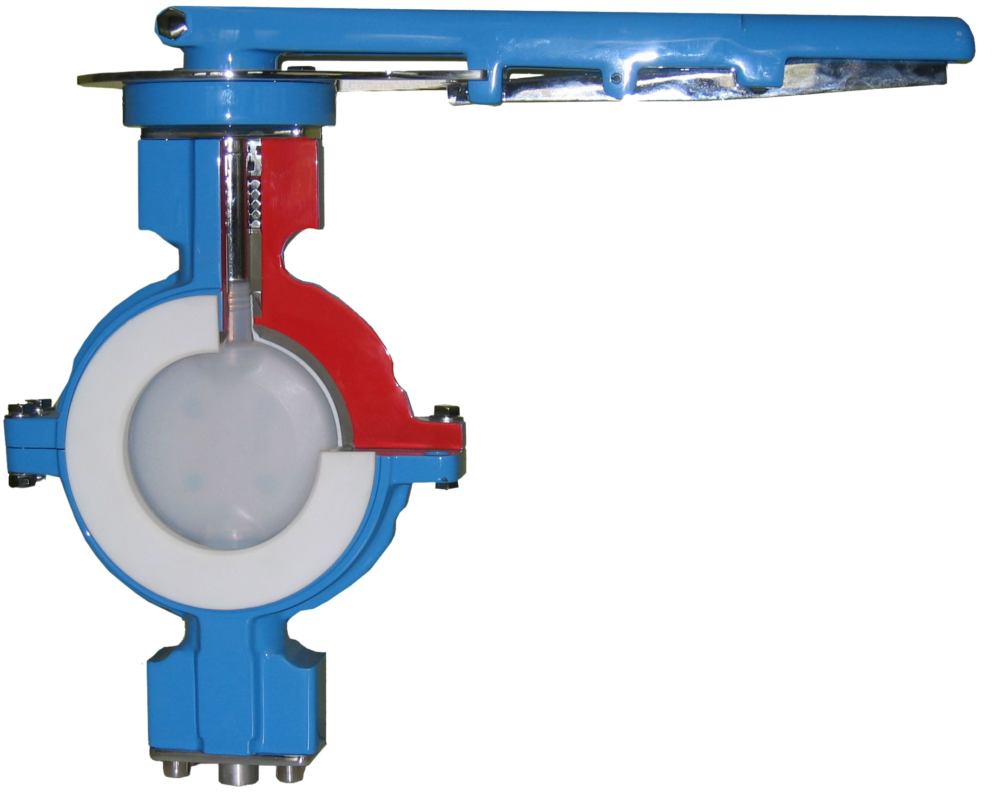

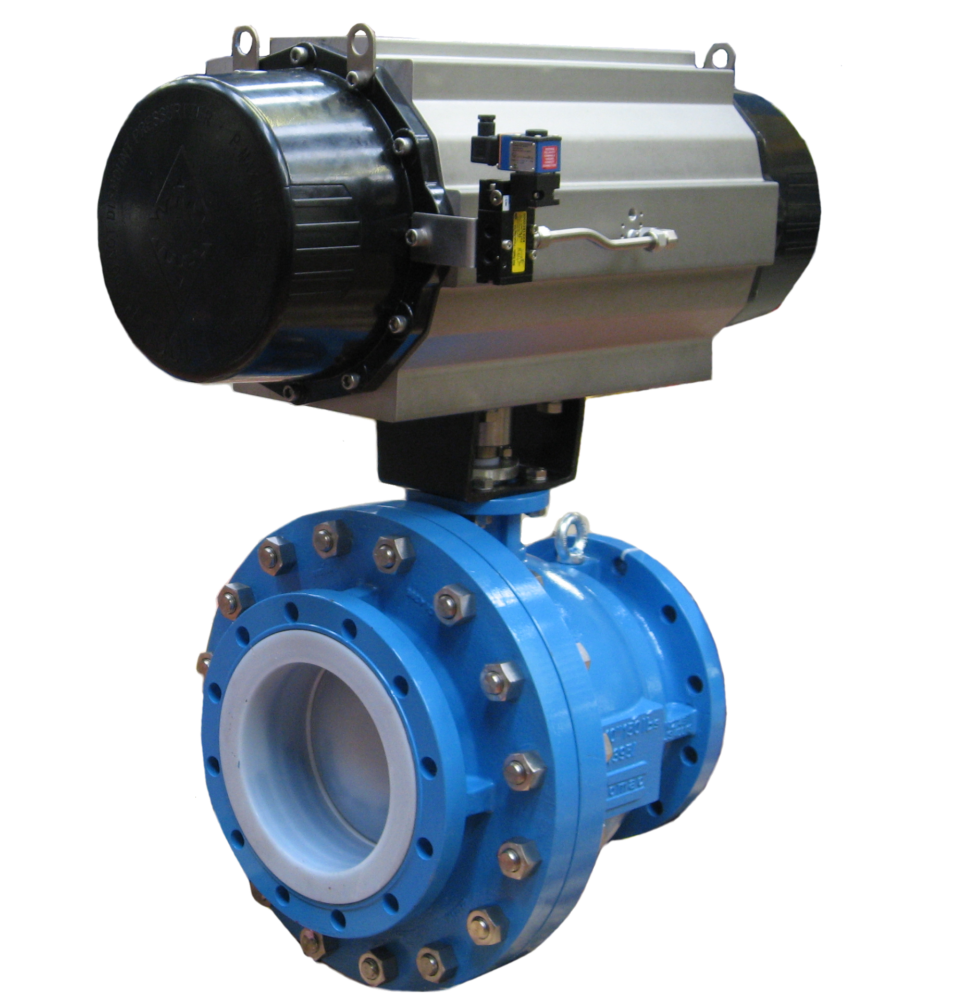

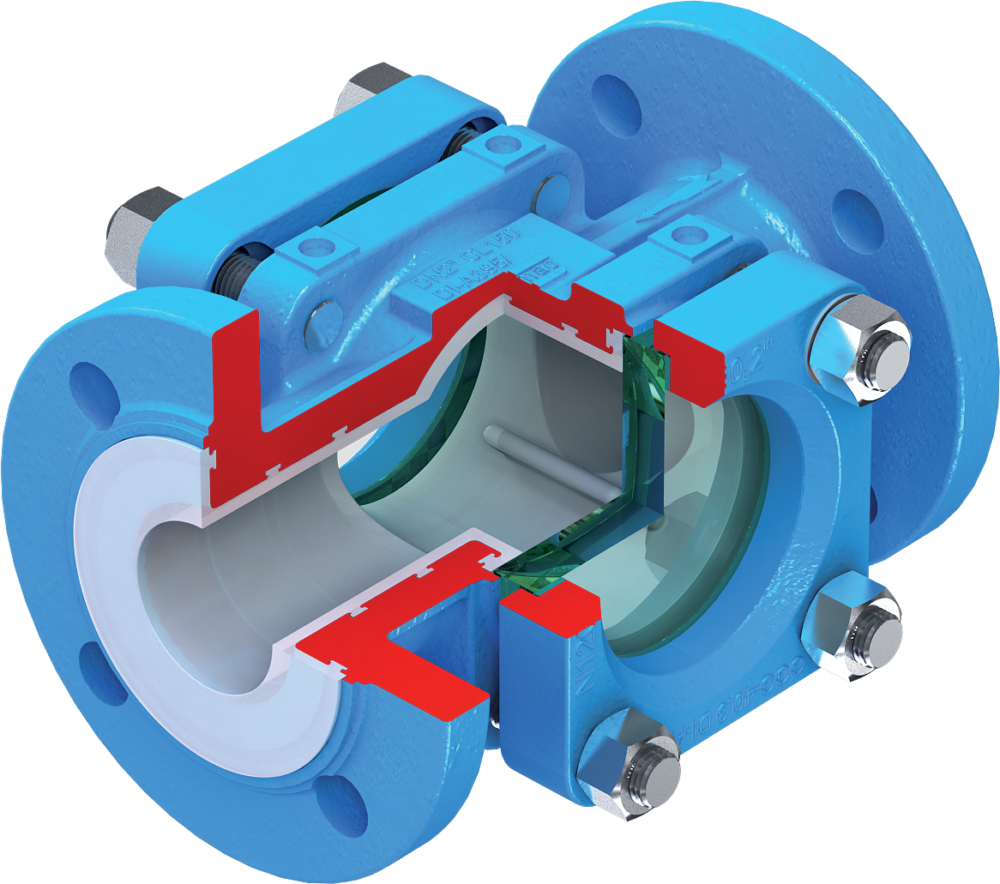

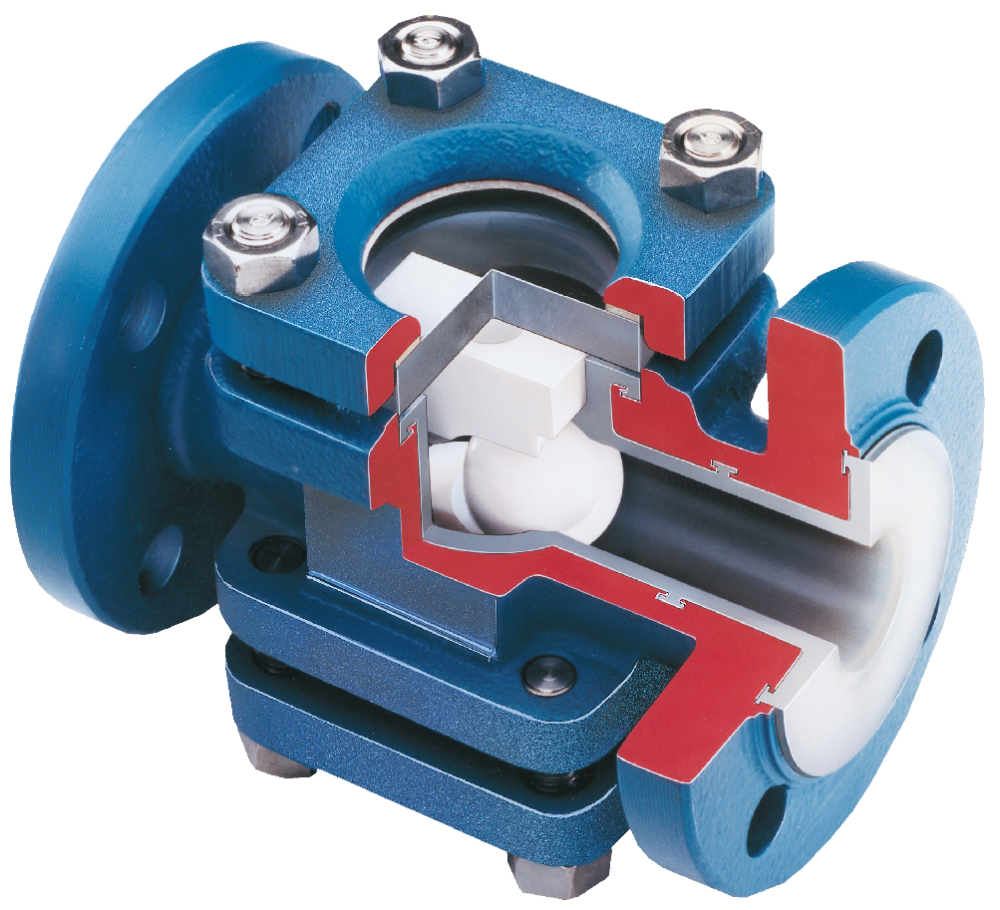

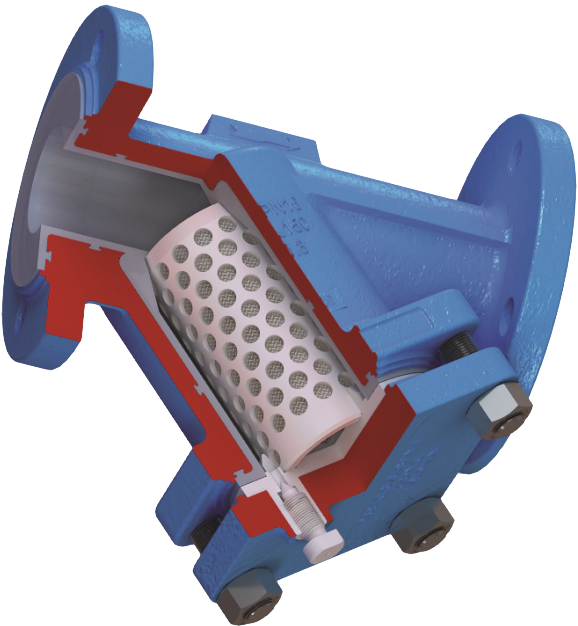

Valves are made as per customer site requirements. We use the Atomac range of valves for PFA lined sampling systems, as they have a long service life and are robust.

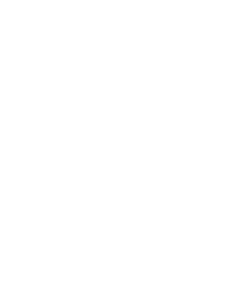

View the sample safely

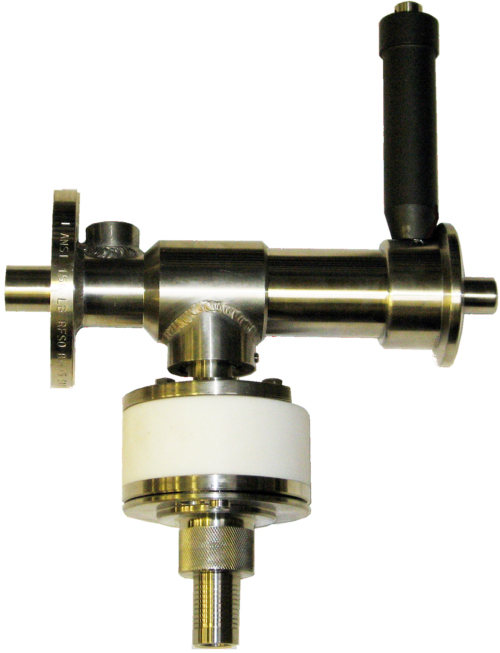

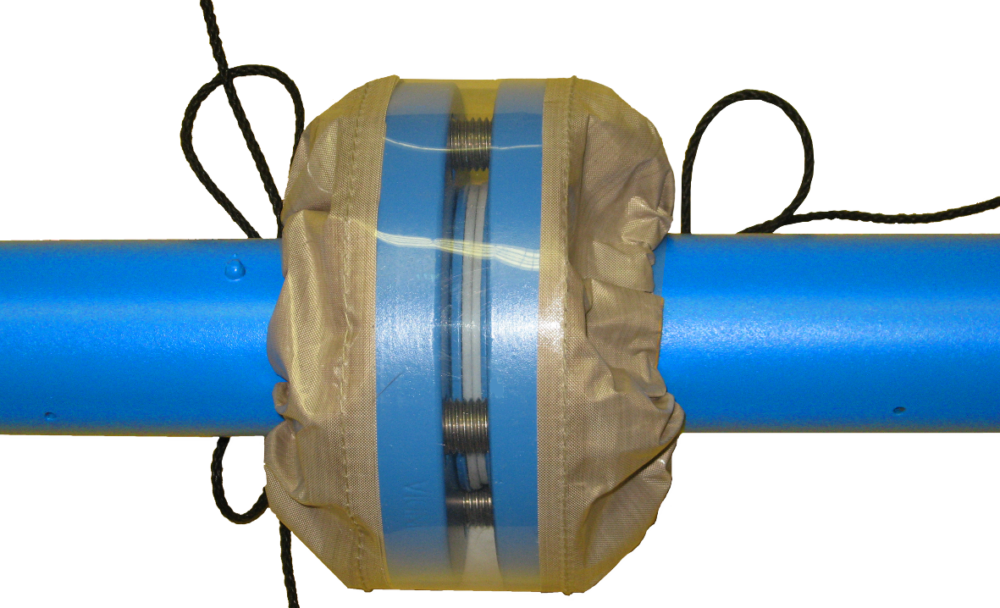

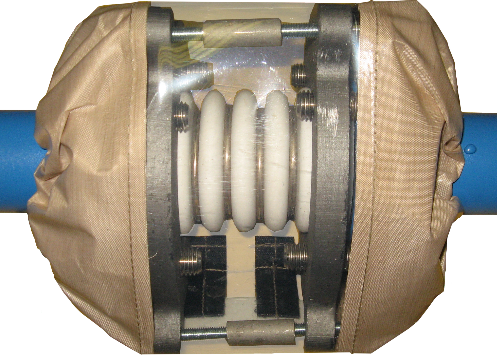

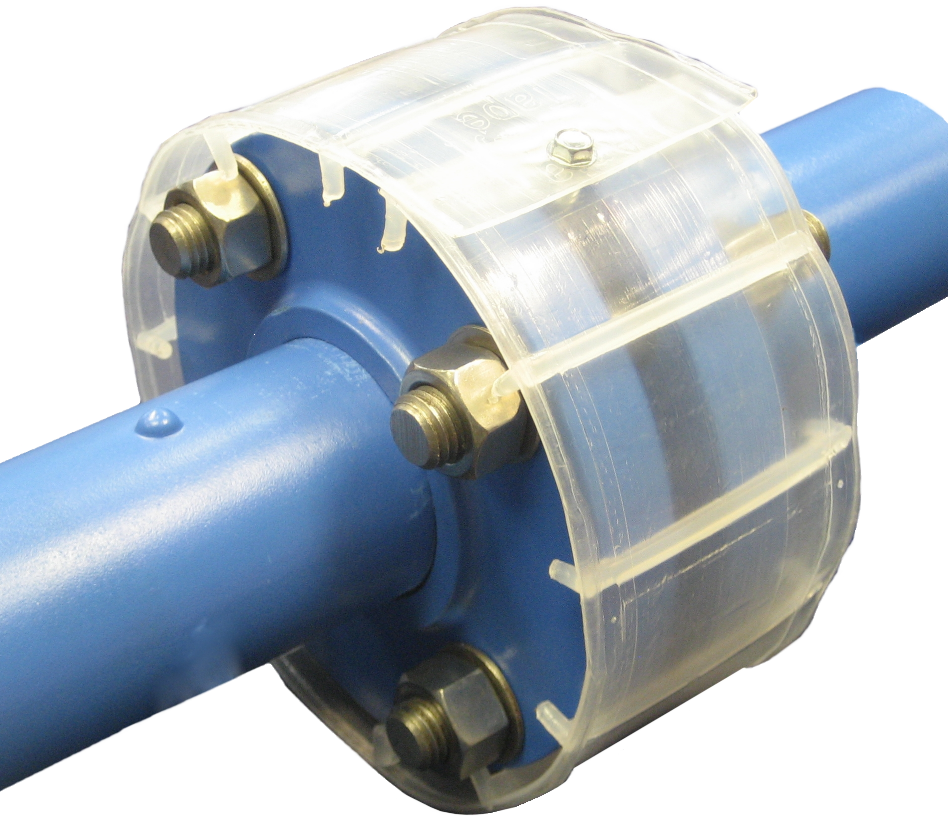

The sight glass section has an outer acrylic safety shield and is constructed from a robust 0.35″ wall borosilicate glass tube. The section contains a hollow PTFE ball which floats on the sample liquid and sits on a castellated PTFE seat. There is a Chemraz FFKM soft seat at the top of the sight glass section, which seals against the floating ball to prevent any sample liquor being drawn into the vacuum line. There are a wide range of capacity options to suit the sample volume that the customer requires. The acrylic shield can be replaced with a FEP shield where there is a risk of attack from solvents.

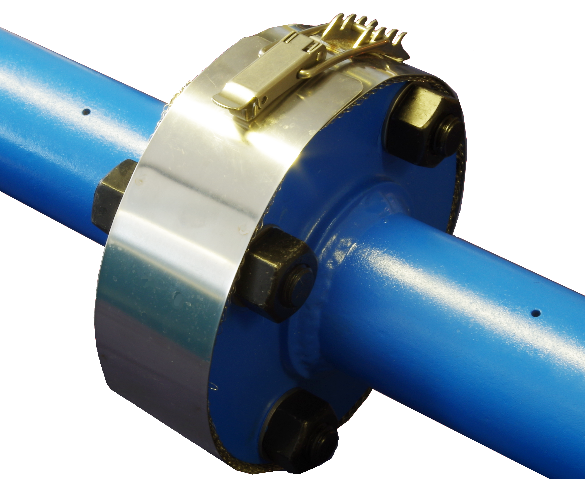

There is a dispensing arrangement below the sight glass section, which can be another valve to release the sample into the sample bottle from the sight glass section. Alternatively, we would recommend that a SD IL 400 inline sampler is used as it has no product hold up areas, with a spring loaded safety handle and a lockable design.

This lower dispensing manifold is bolted to a vessel isolation valve which is usually connected with a reducing flange to the dip pipe process flange. Along with any sampler we will be happy to supply a fully PTFE lined dip pipe.

The maximum working pressure is 145 PSI and the maximum operating temperature is limited to 356° F.

Let us know your special requirements.

We can produce special designs, for example with bulls eye sight glasses and Belleville washers for cryogenic services, high temperature applications and more. We can incorporate eductors to produce the vacuum required using a compressed gas source if site vacuum is unavailable.

For typical operating procedures click here.

As with all our samplers and sampling systems, we recommend that the sample bottle is contained within a safety cabinet to protect the bottle, operator and environment. Our standard cabinet is stainless steel with a laminated glass door.

To help specify a sampling system, please download our questionnaire.