Handling corrosive chemicals is no small task. It requires careful management and adequate safety measures. Among these measures, one stands out for its unmatched protective capabilities: flange guards. These pieces of equipment act as a shield, intercepting accidental spills and splashes that might result from pipe leaks. Hence, they play a pivotal role in maintaining safety where corrosive substances are used.

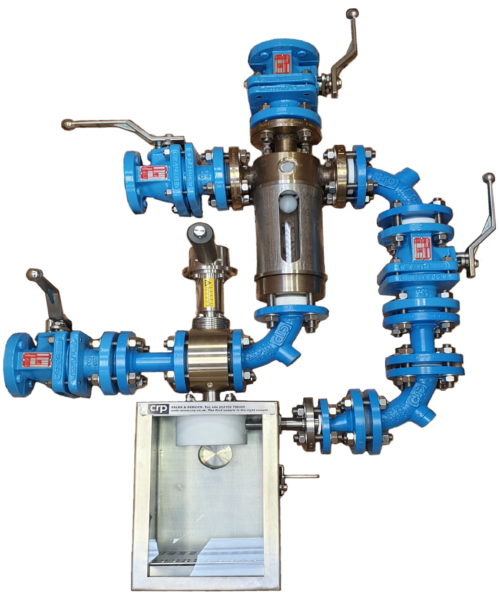

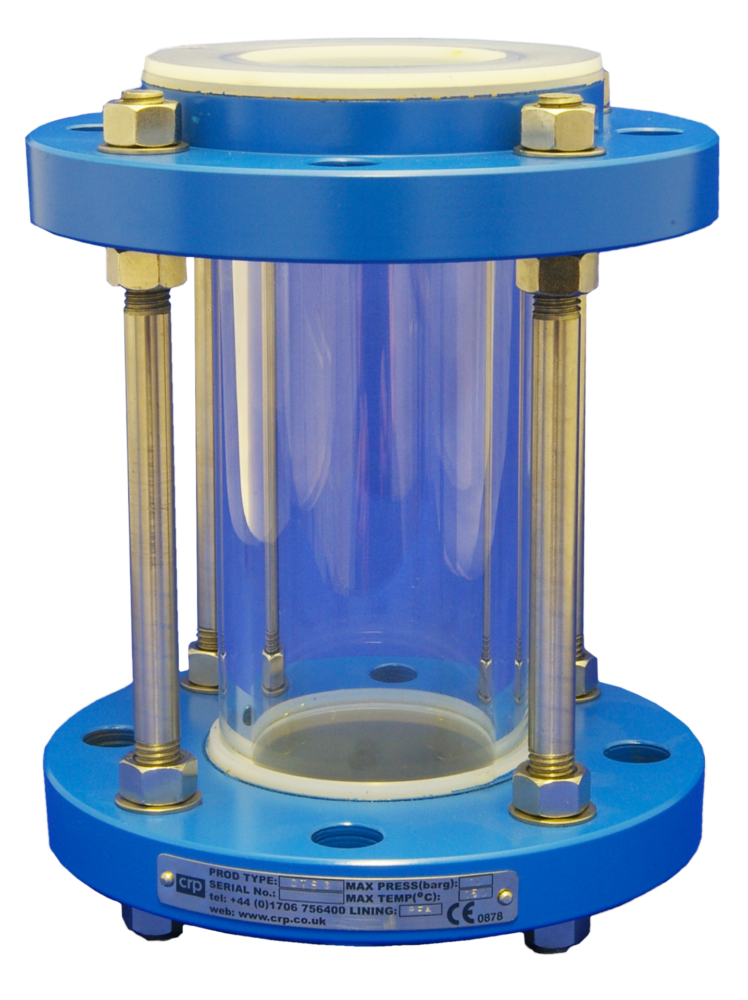

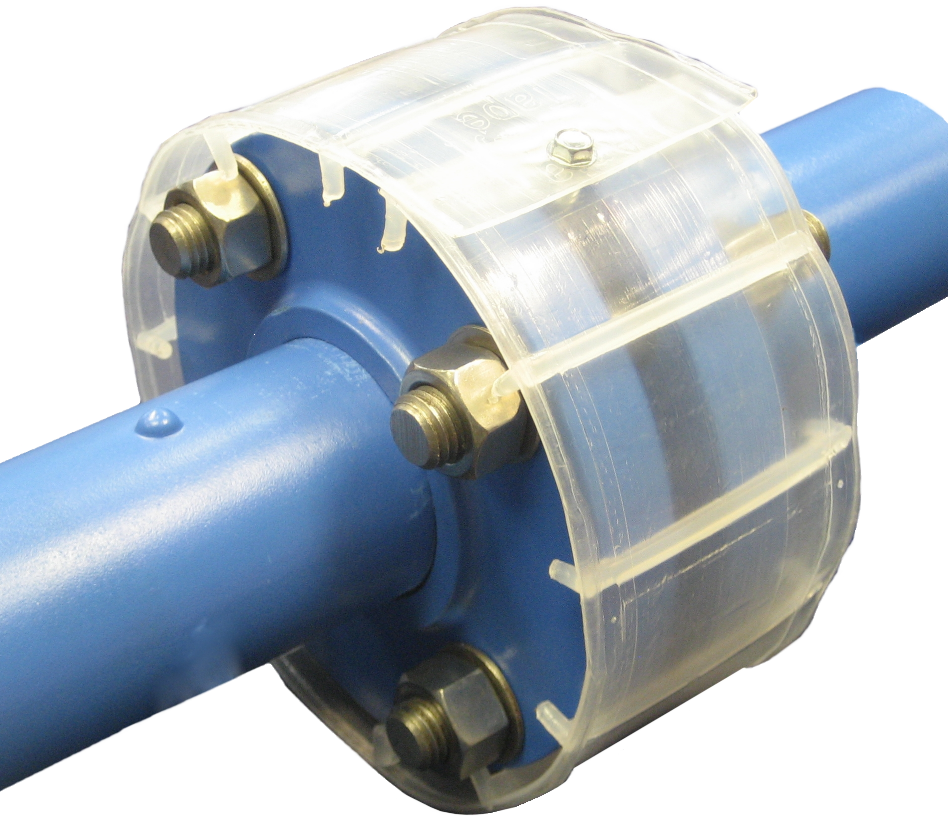

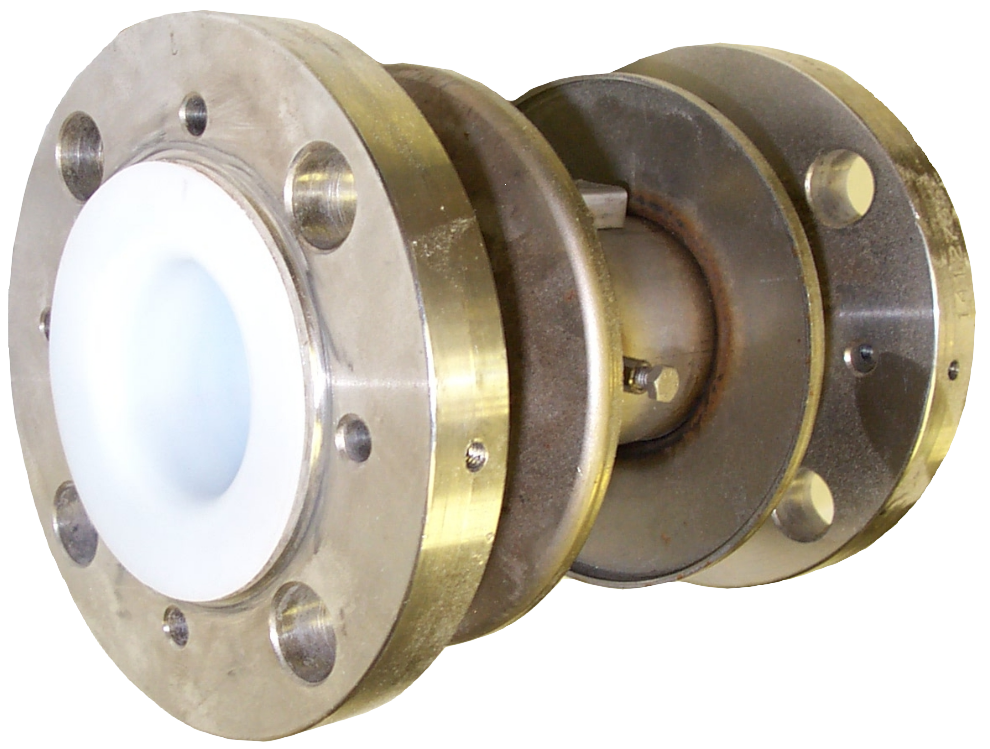

Corrosion Resistant Products Ltd embodies a commitment to safety and innovation with a line of clear Teflon flange shields offering top-tier protection. Crafted from corrosion-resistant materials, these guards provide a clear view of pipe connections. This allows for easy visual inspection, helping nip potential bud leaks.

Understanding Flange Guards

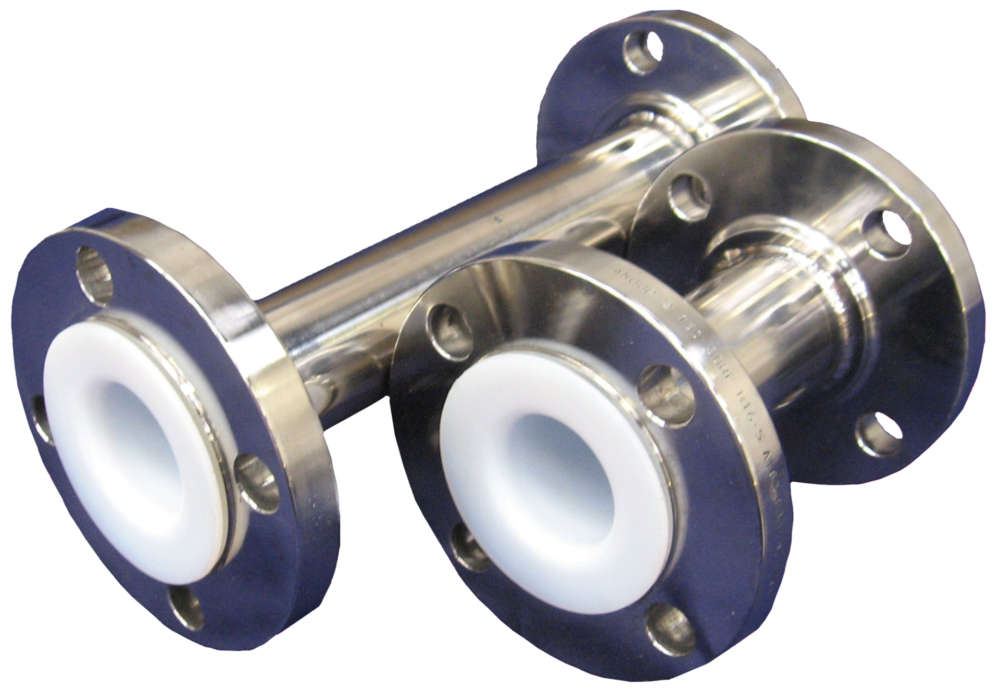

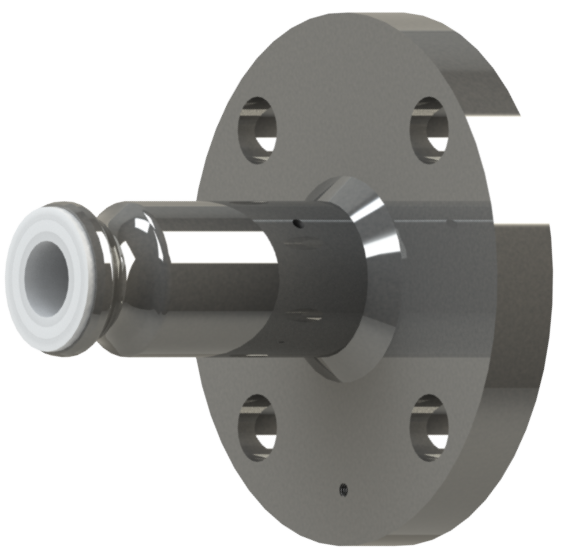

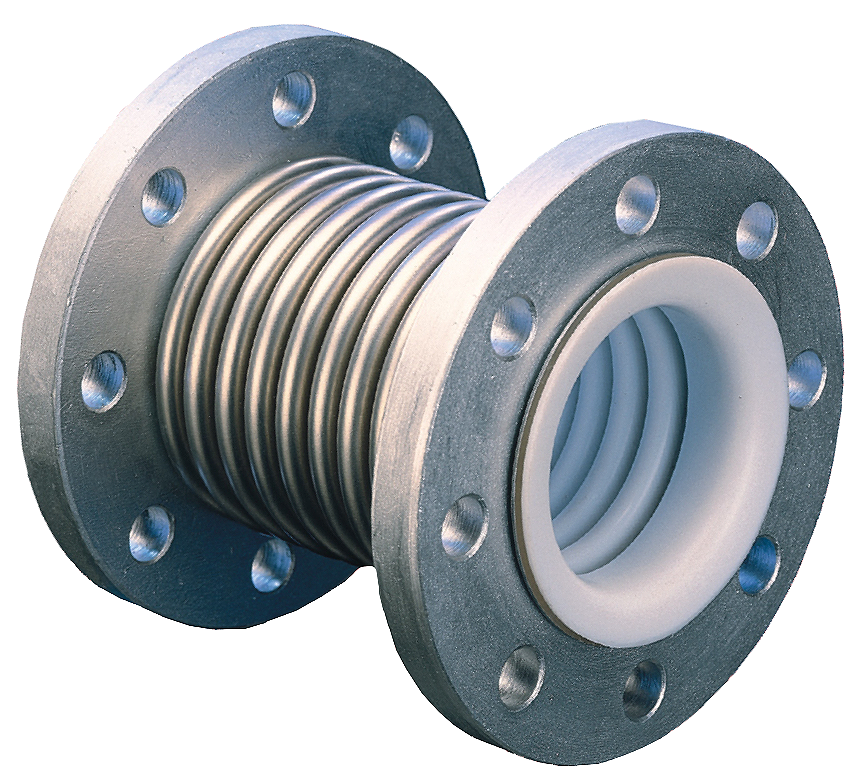

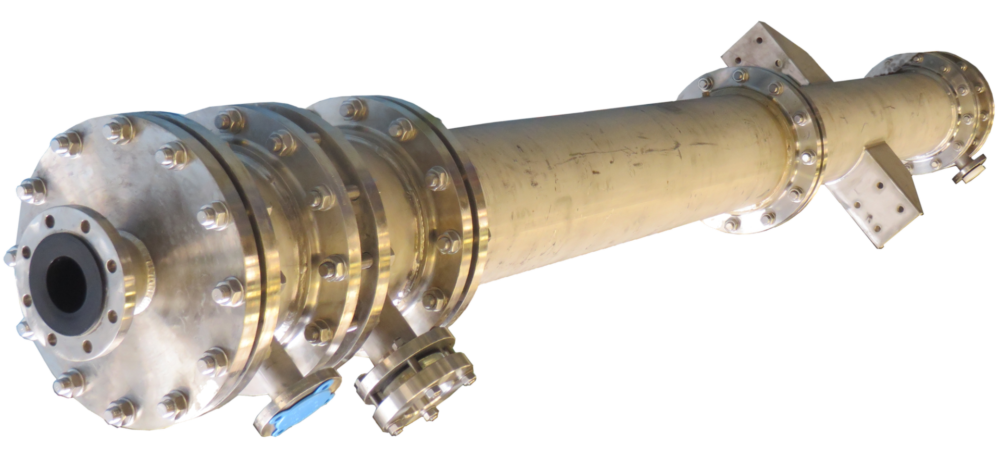

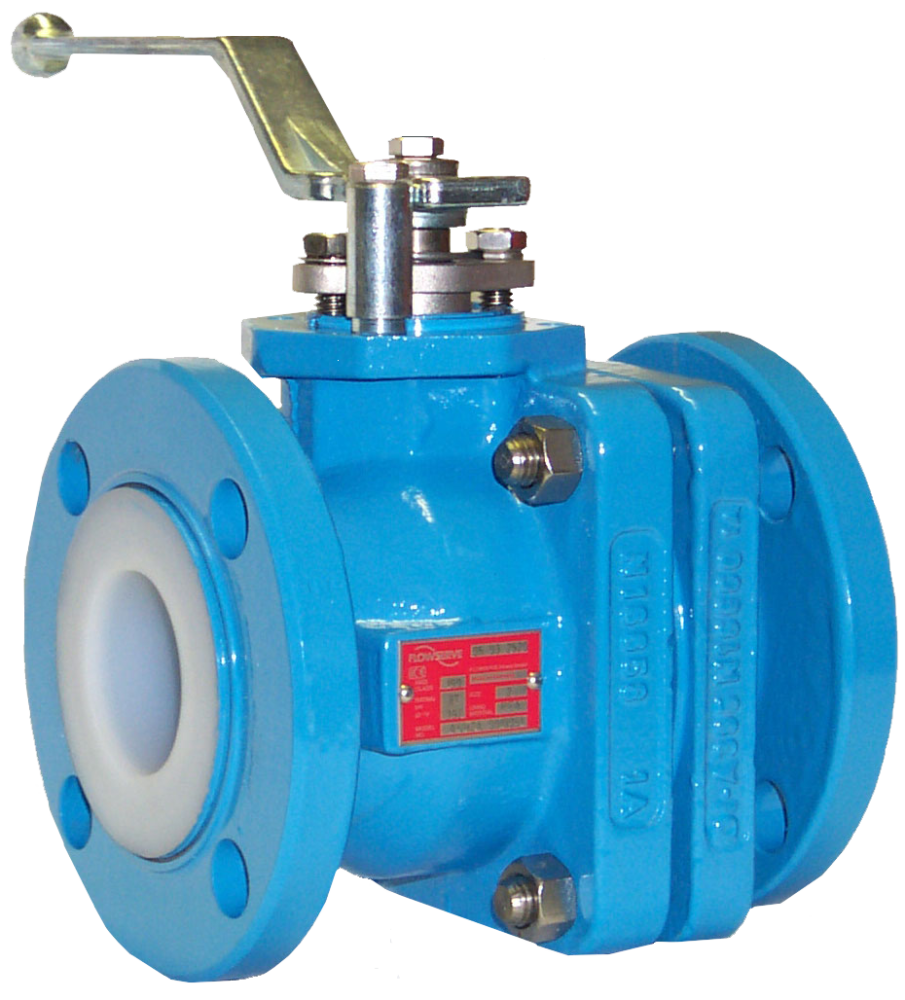

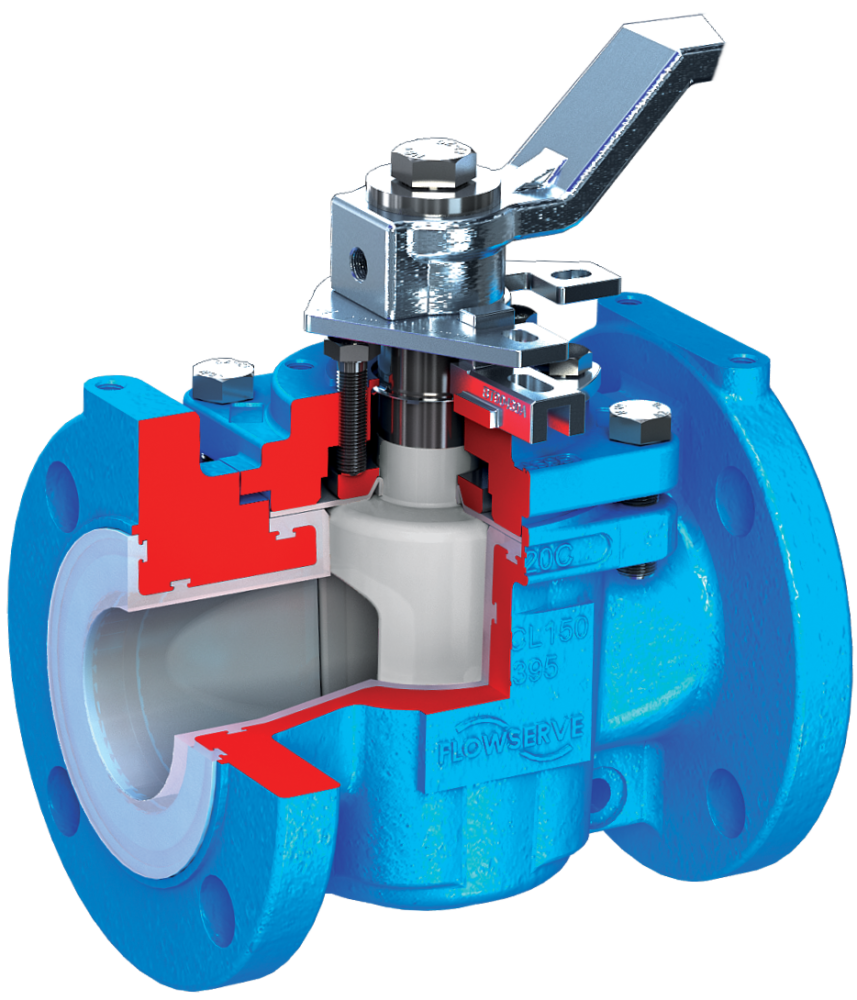

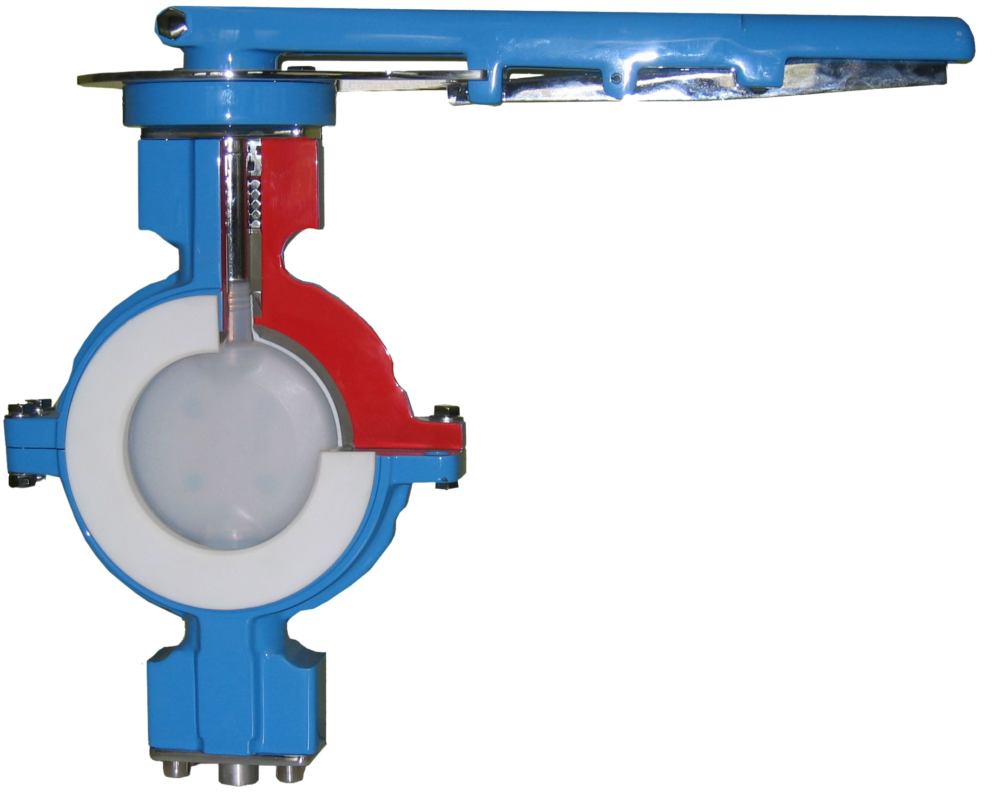

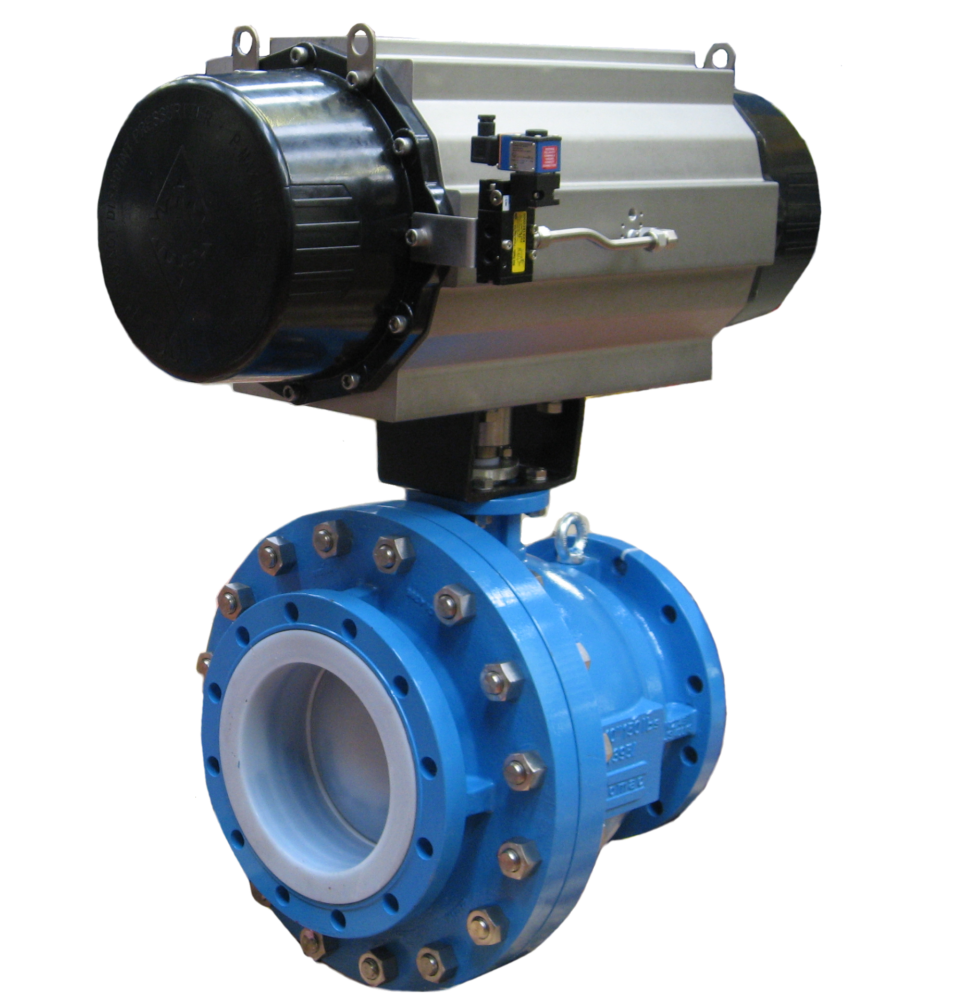

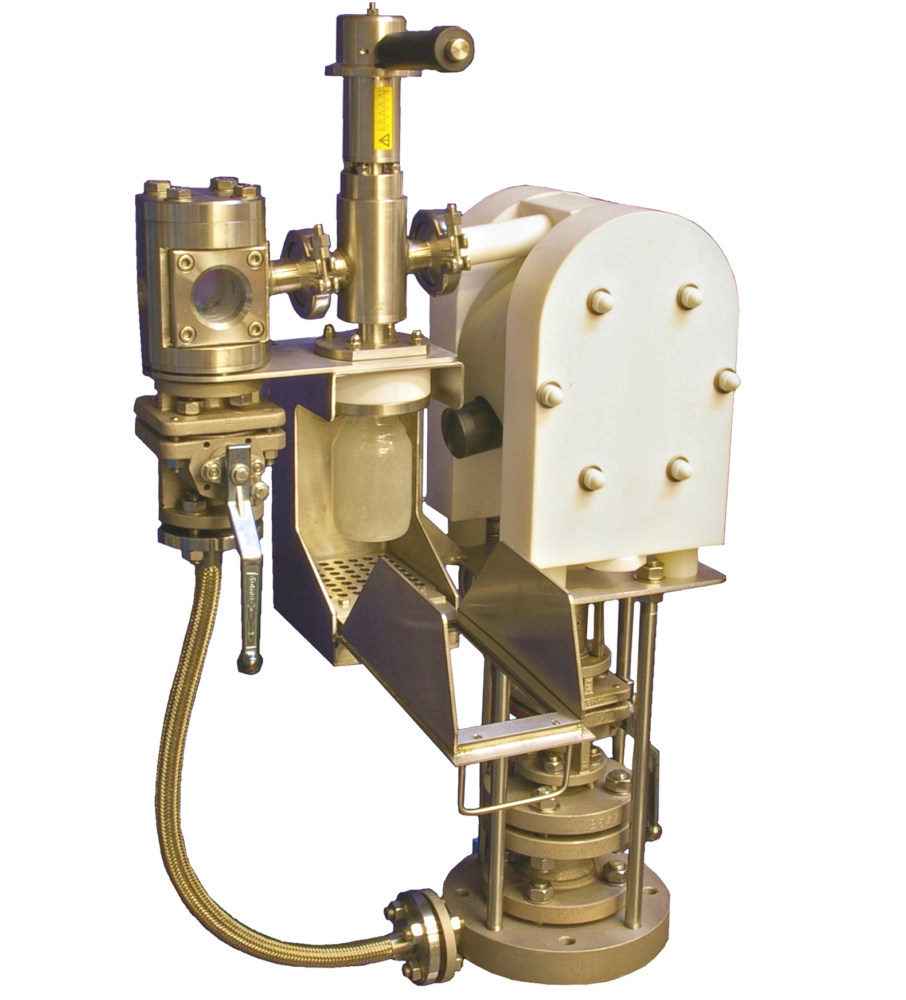

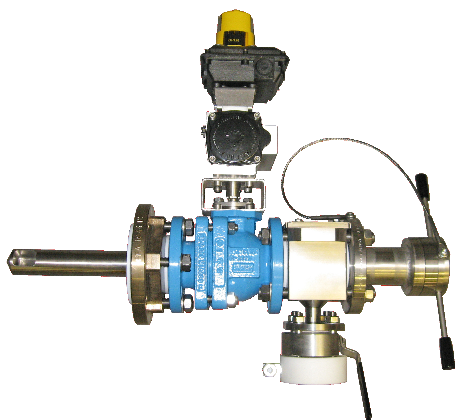

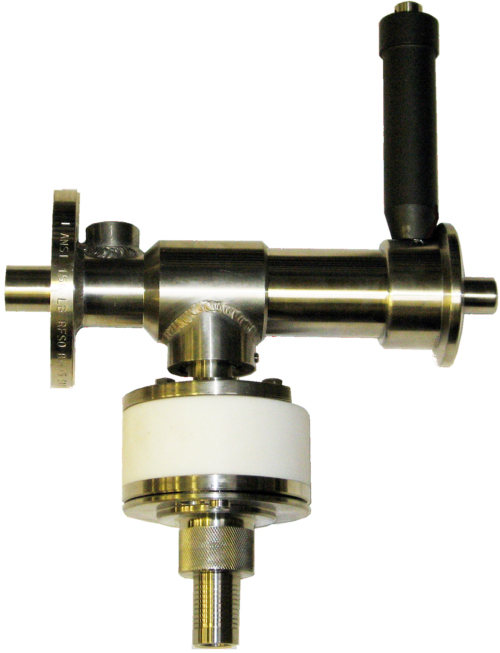

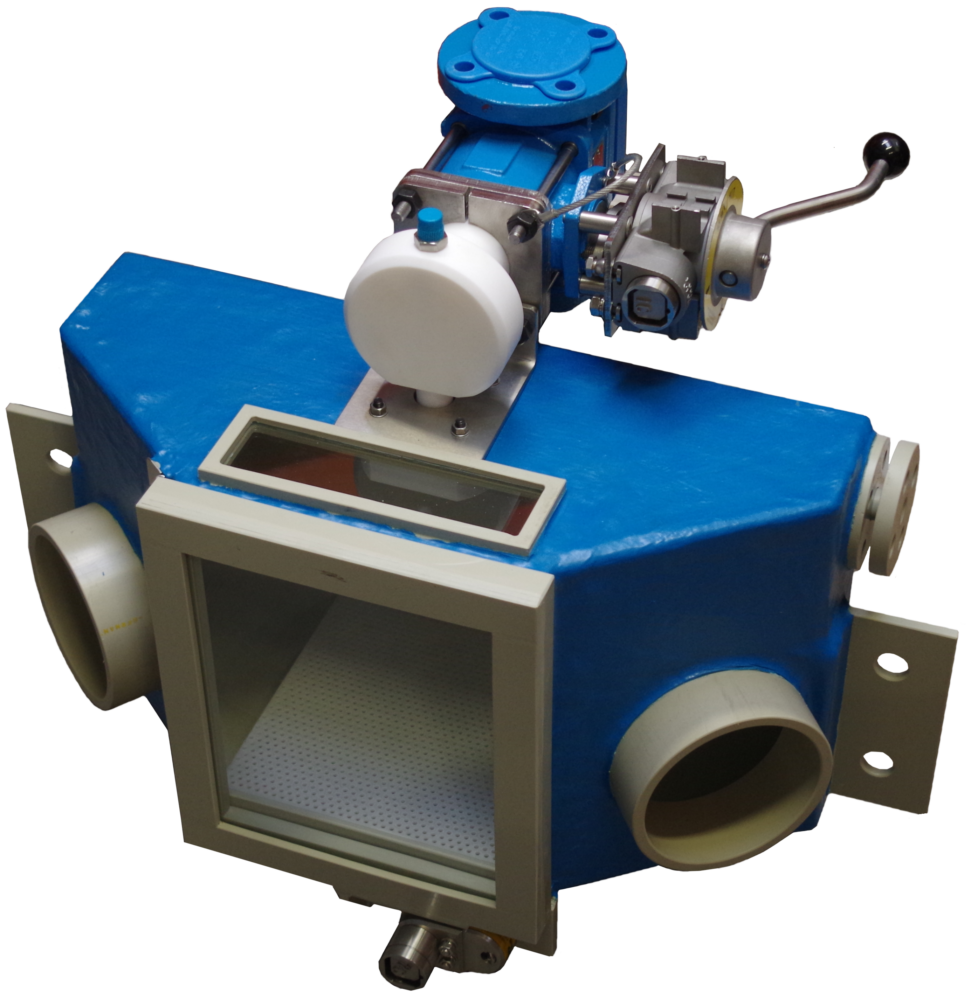

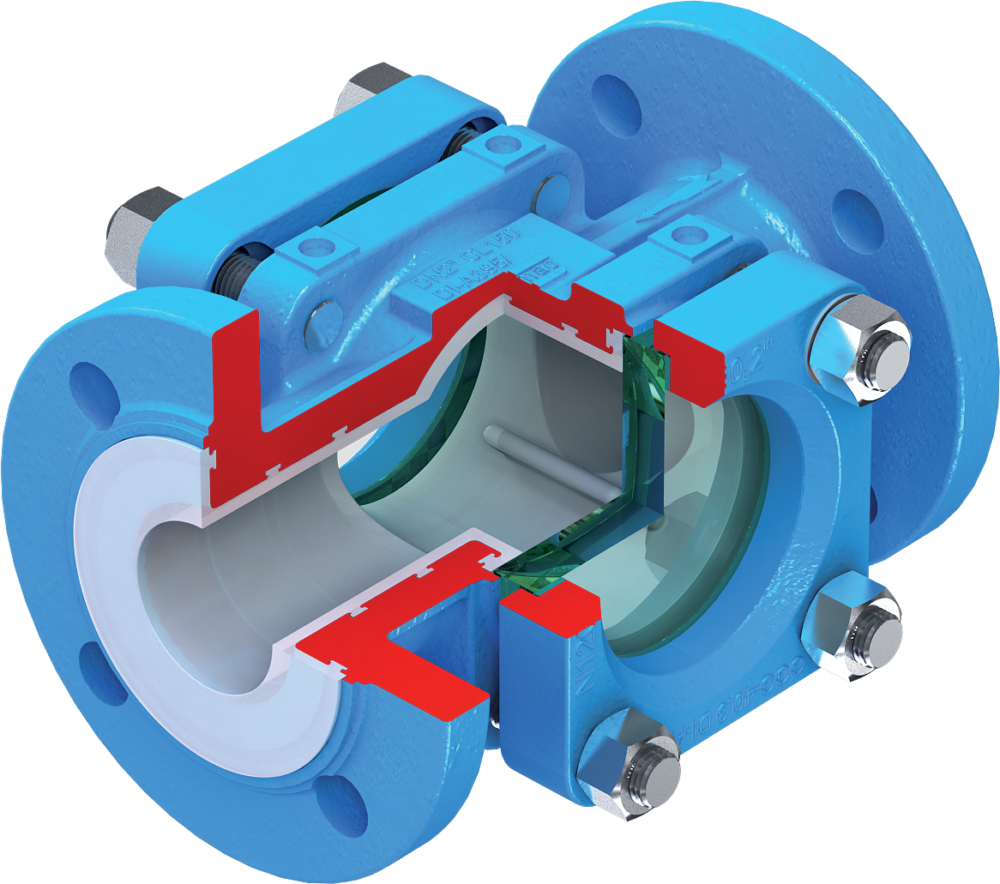

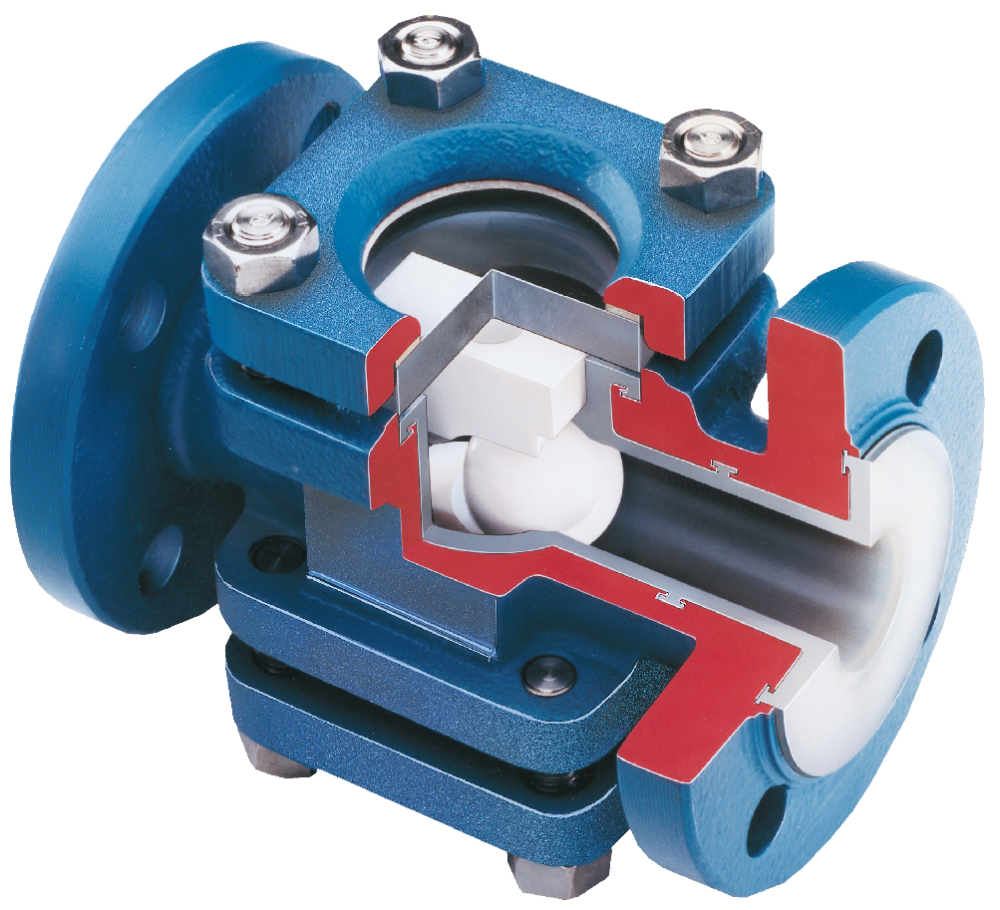

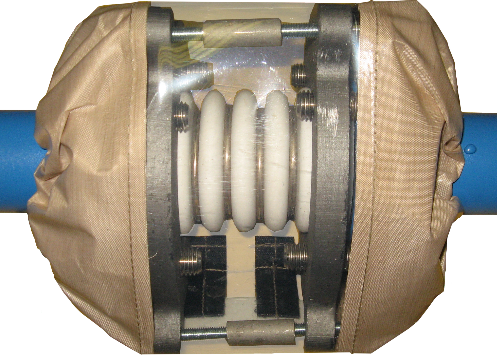

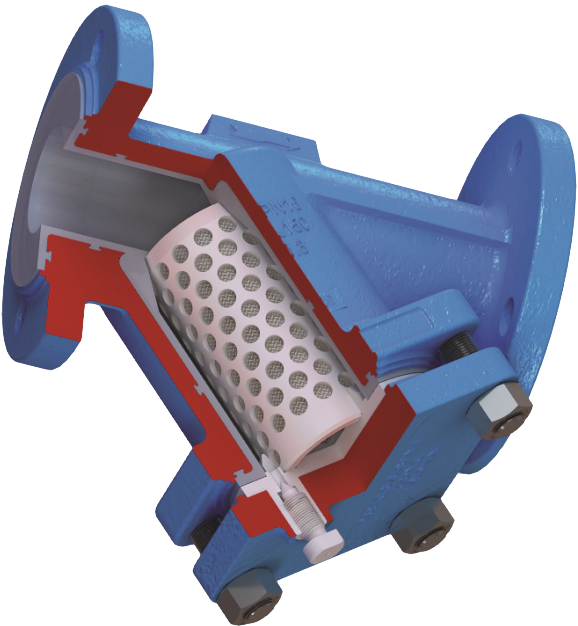

Flange guards are protective covers designed for industrial pipe joints prone to leaking or spraying hazardous substances. They are manufactured from PTFE, PVC, and stainless-steel materials to suit different industrial needs.

When a leak occurs, the fluid encounters the flange guard first, preventing immediate escape. The guard then redirects the substance safely away, minimizing the risk of accidents and exposure to harmful chemicals.

Types of Flange Guards

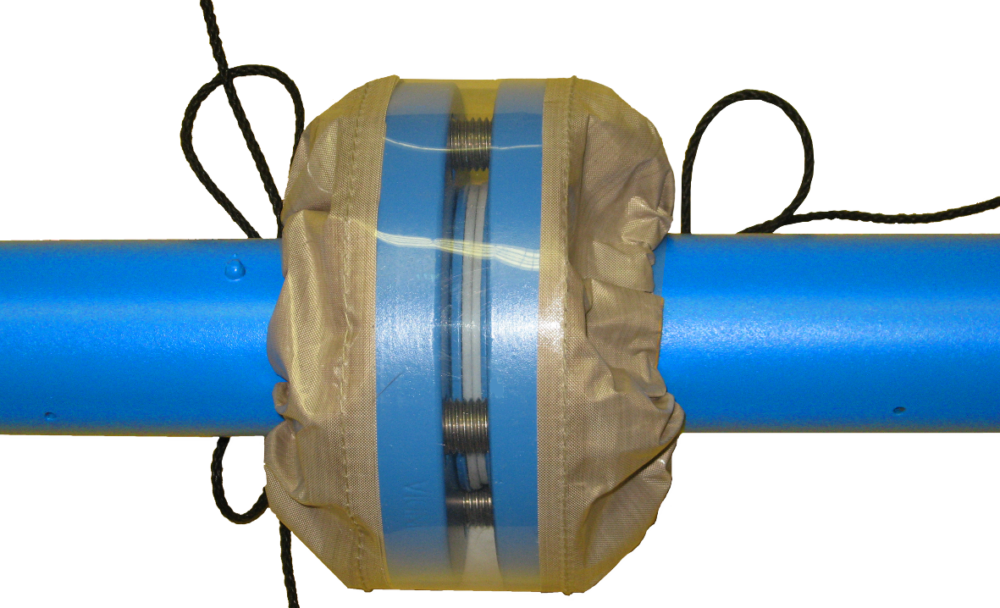

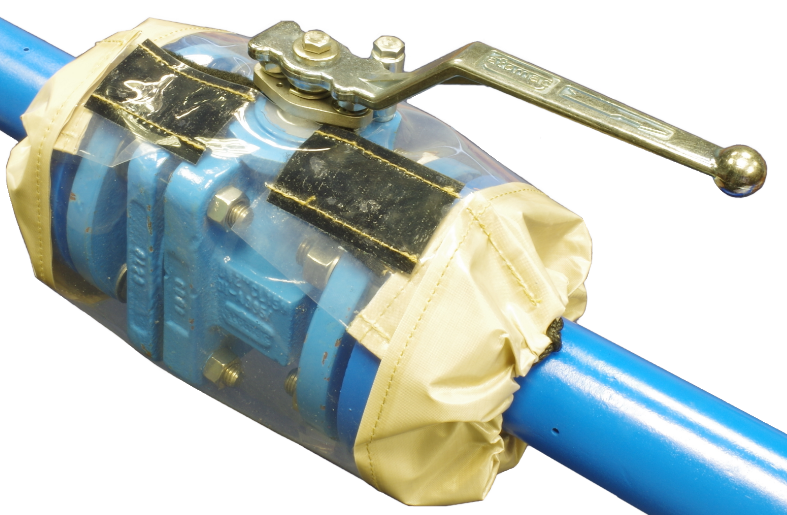

Various flange guards are available, each tailored for specific applications based on their material and design. Options include spray shields, clear-type shields, and metal shields.

Spray shields are particularly effective for handling common leaks and are typically made from materials like Teflon or Polypropylene. Clear-type shields offer the advantage of visual leak detection, while metal shields are best suited for areas with high temperatures due to their heat-resistant properties.

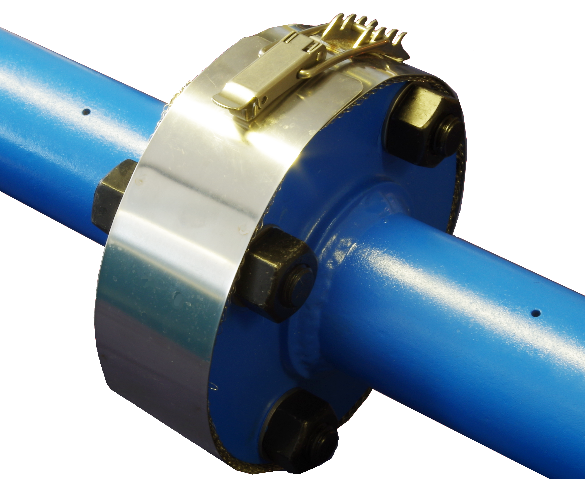

Installation of Flange Guards

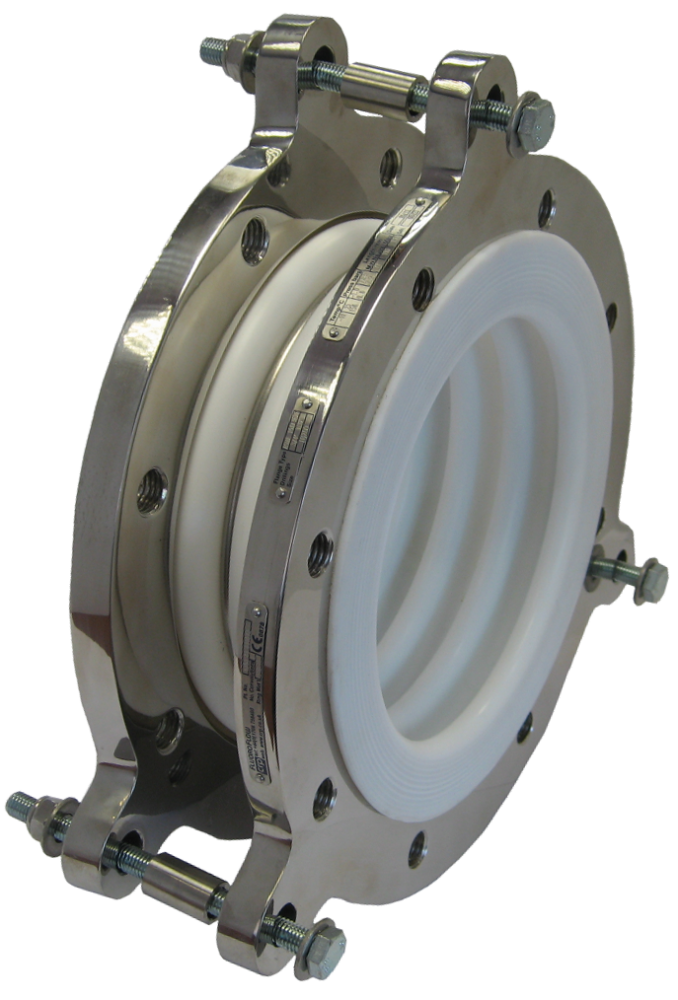

Installing flange guards is a straightforward process. They are designed to be easily fastened onto flanges and joints with mechanisms such as drawstrings or quick latches, allowing for simple installation and removal by workers.

The procedure is quick: the guard is wrapped around the relevant flange or valve and then secured tightly using the provided mechanism, ensuring a reliable fit.

Maintenance and Care for Flange Guards

Regular maintenance is key to ensuring the longevity and effectiveness of flange guards. A typical regimen involves checking these protective devices every six months to identify signs of wear, dirt, or damage.

A flange guard must be promptly cleaned or replaced if it is dirty or damaged. This proactive approach ensures that the guards continue functioning as intended, maintaining safety standards and reliability.

Notable Benefits and Applications of Flange Guards

Flange guards offer numerous advantages, acting as a vital safety measure in protecting workers from chemical exposure and safeguarding equipment from damage due to corrosive leaks. Their cost-effective nature, ease of installation, and minimal maintenance requirements make them a preferred choice in many industrial environments.

The protection and peace of mind provided by flange guards make them an invaluable addition to industrial settings, contributing significantly to the safety and efficiency of operations.

Safety Shields: Increasing Protection, Reducing Risk

Take the next step in improving your company’s safety standards. Reach out to Corrosion Resistant Products Ltd. today. In this light, we offer other safety shields and flange guards. Maximizing protection, these shields act as an added security layer in your pipe system, reducing risks and making the chemical handling process safer.