Project Handling

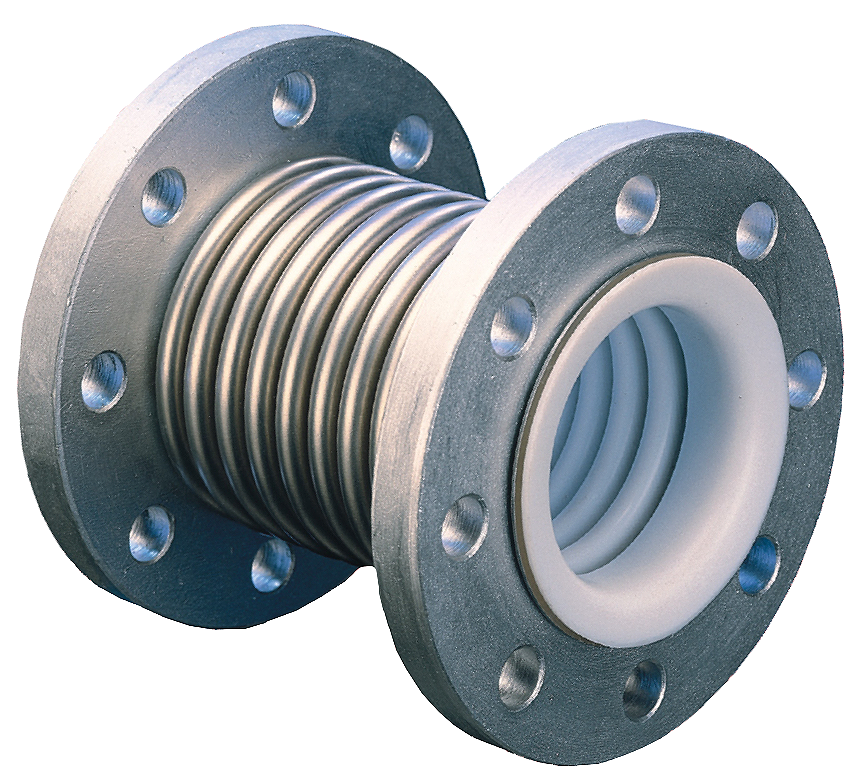

CRP has had many years experience in successfully supplying lined piping and valves to large scale projects. Our lined piping has been supplied into some of the largest pharmaceutical plants within the UK. Over this period we have constantly strived to improve our service to the customer offering many additional cost saving benefits. Our project supply management model is now, we feel the best available.

The CRP Project Supply Approach

Project Procedure Document

Before we embark on any large project we draft a very detailed supply procedure document and issue to all parties concerned. This document contains all contact details, pricing arrangements, delivery expectations and product specifications. In fact all the technical and commercial aspects agreed by both parties. By having this document drawn up at the very start, there are no surprises for either party later in the project. The document is revised as required and reissued throughout the project life.

Isometric Take Off

Our project team creates manufacturing orders straight from the isometric drawings, there is no need for the customer to employ their own engineers to this. Each isometric has its own sales order and our manufacturing processes are prioritised by isometric. Any agreed joint reduction programmes etc is done at this stage.

Dispatch Documentation Compiled

The isometric drawing is marked up to identify each item we are supplying cross referenced with the sales order acknowledgement / delivery note. A copy of the drawing and dispatch note is supplied with each consignment of goods ready for the installation team on site.

Manufacturing Log

A project specific manufacturing log is created to detail each stage of manufacture of each of the isometric drawings. This is issued to the customer weekly. As installation priorities change we are able to realign our manufacturing to suit against each isometric. This is can be extremely beneficial to the customer.

Project Stock

Kanban control systems are used throughout our supply chain to drive procurement of stocks of raw materials. Additionally, we manufacture in advance of isometric drawing receipt against projected forecast requirements.

Special Paint Finishes

Items are manufactured using our standard works procedures. However often customers choose to have additional paint application and finishing, typically this can be several coats of primer, intermediate and top coat to give a very long lasting finish. The grit blasting and all painting is all conducted in house so we maintain total control, both of timescales and quality.

Tagging

All items are tagged as required, this is typically the isometric drawing number and item number and our sales reference number. To give full tie up on site with the working documents.

Kitting by Isometric

Items are then collated and packed together so that all the items are available to construct an isometric on site without the tiresome task of hunting for components.

Packed and Identified

Finally we ship the items to site with crates that are clearly marked with the isometric components they contain so the crate can be taken to the appropriate area on site to make installation straight forward as possible.