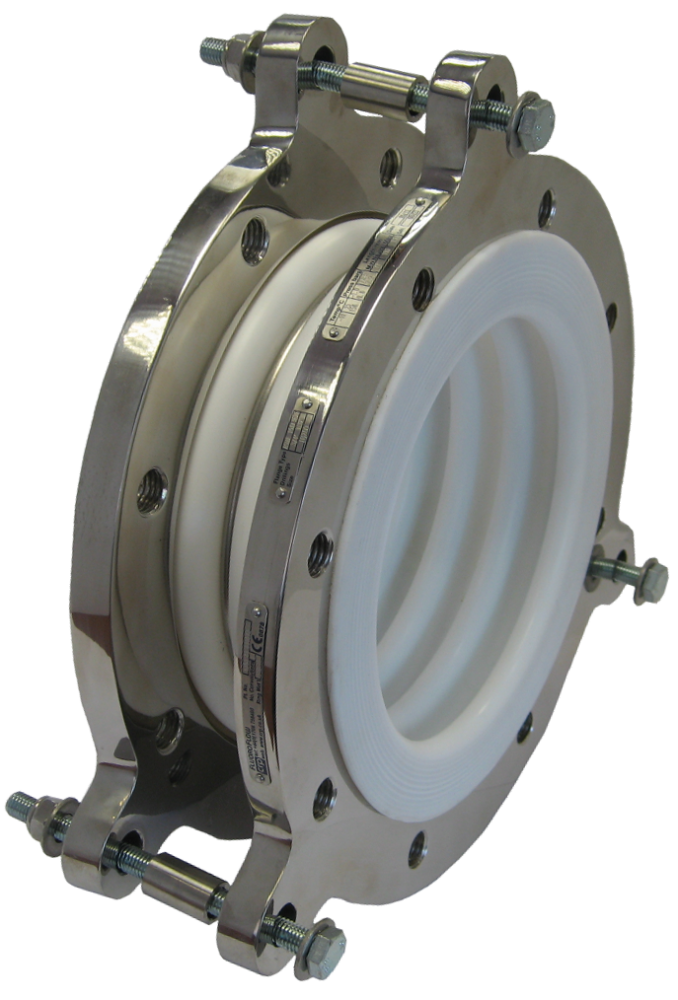

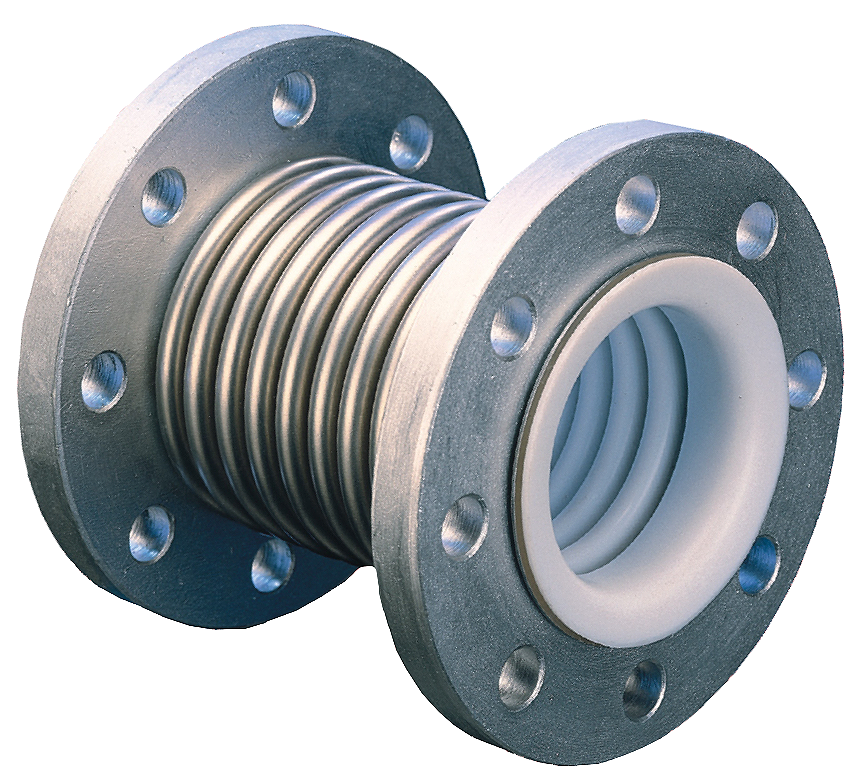

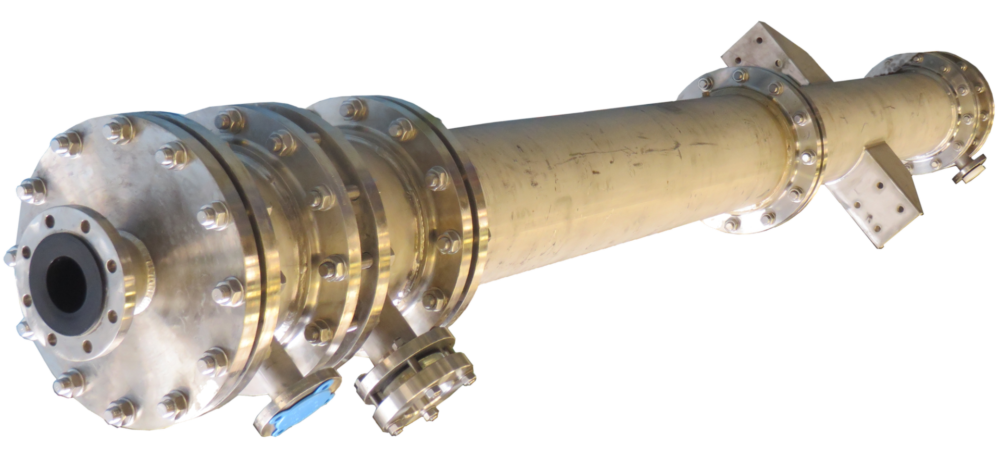

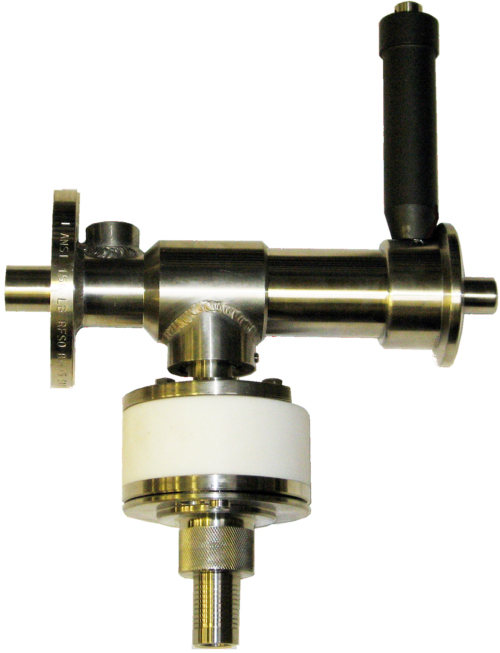

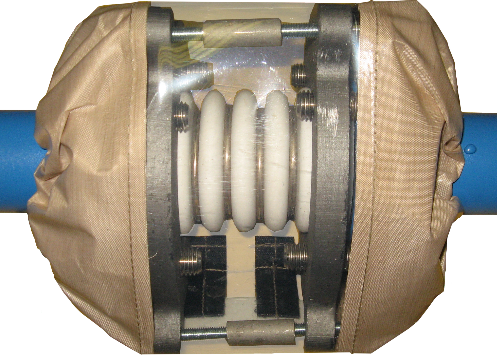

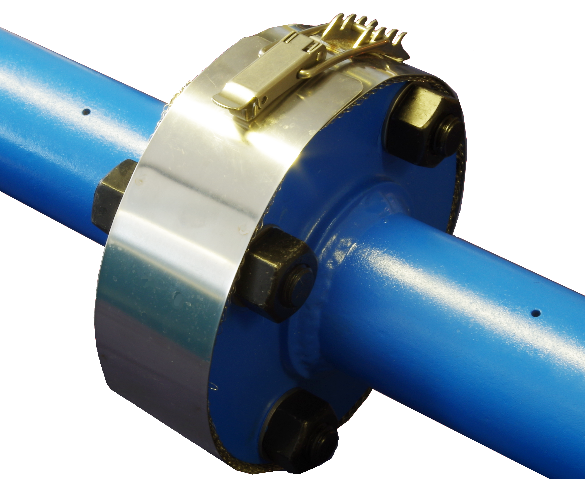

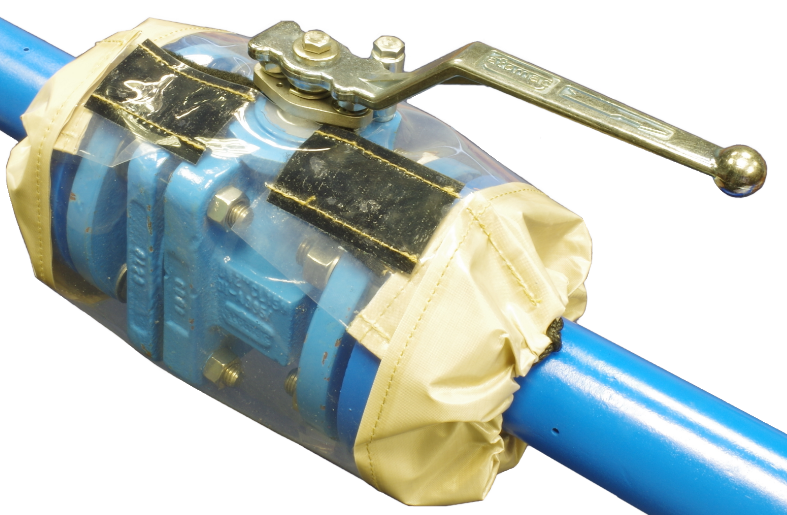

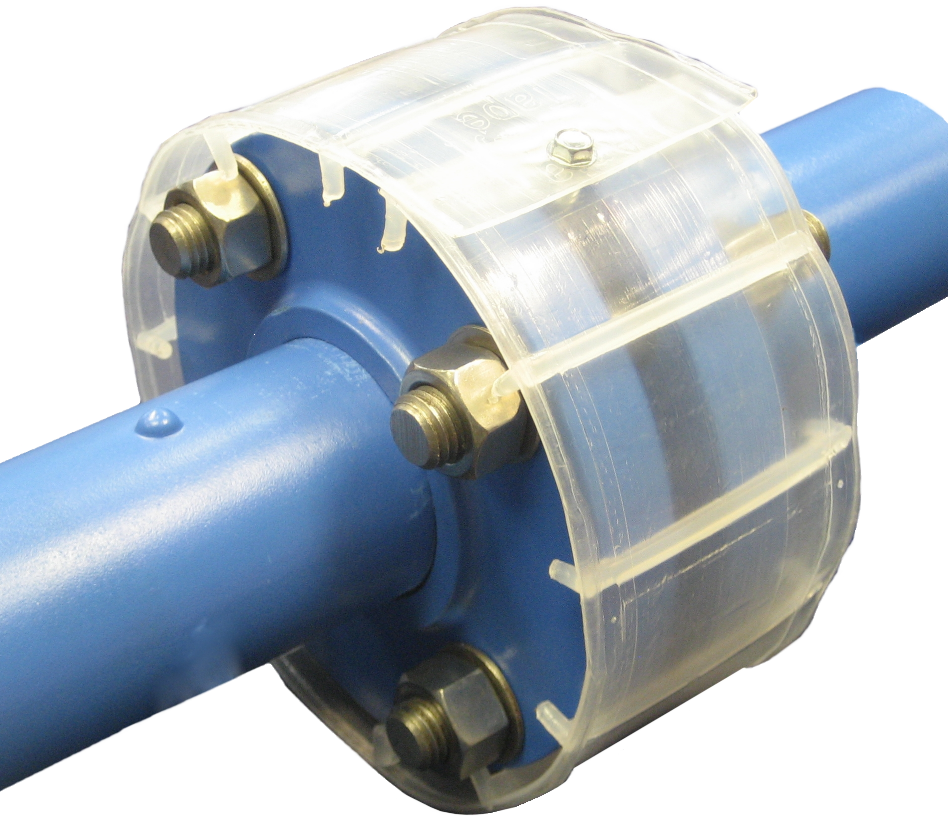

PTFE Expansion Bellows

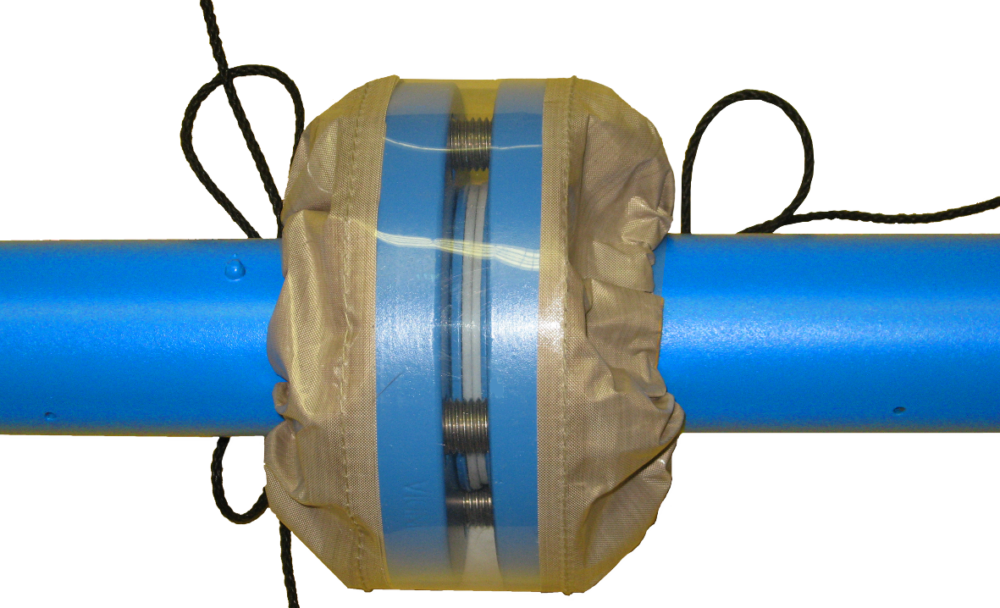

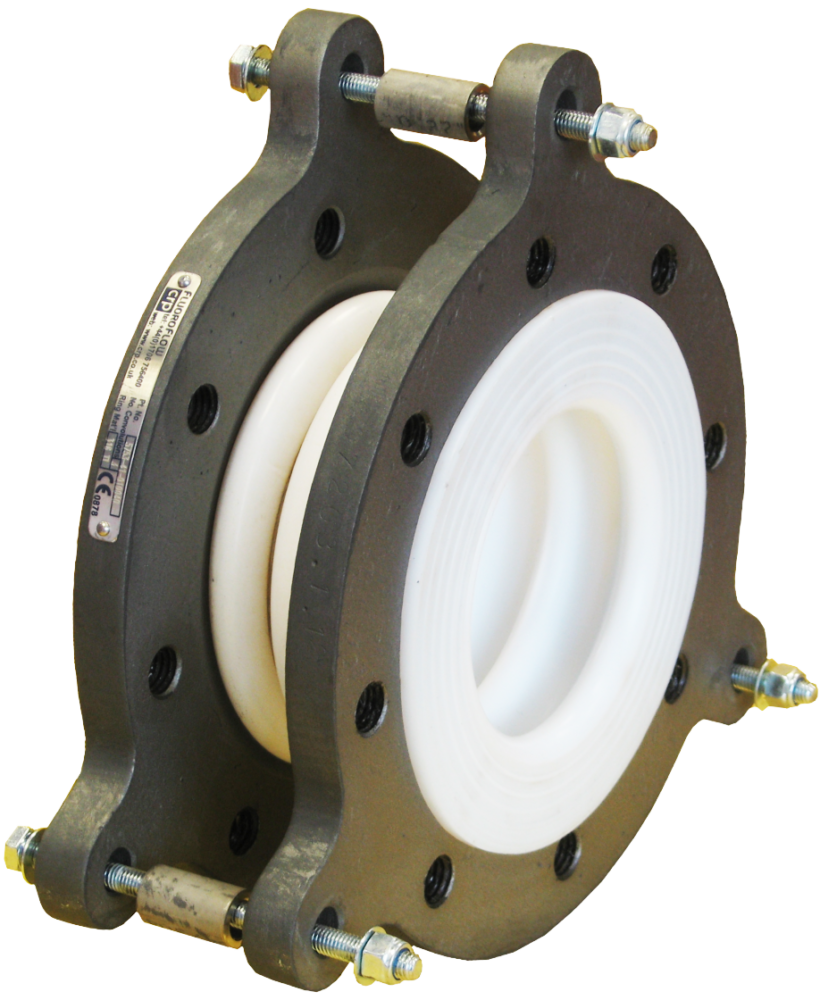

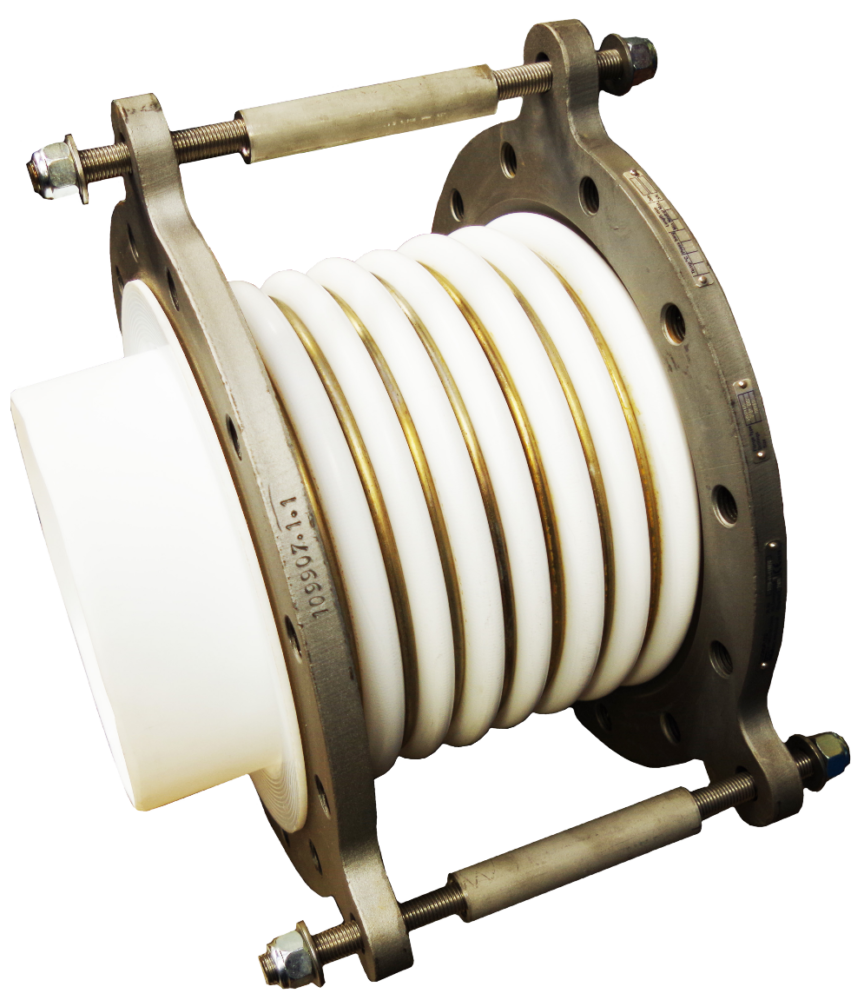

CRP manufacture PTFE expansion bellows used to reduce vibration and take up thermal expansion in pipelines. Usually supplied with ASME / ANSI 150 steel flanges with maximum working pressures up 232 psi! The 3 convolution bellows is our most popular offering the highest pressure ratings coupled with reasonable axial, lateral and angular movements. Where larger movements are required we manufacture bellows with up to 10 convolutions providing very large movements. The PTFE bellows not only compensate for thermal movements, but can also reduce vibrations along pipelines, compensate for slight misalignments, absorb sound and protect more delicate joint materials such as when connecting to graphite heat exchangers.

Thousand of Bellows in Service

CRP flexible expansion couplings have been manufactured for decades with thousands of bellows installed providing long service in chemical plants and water treatment plants all over the world. Most of our customers appear in the top Chemical Producer list and we are proud to supply PTFE bellows to the worlds largest chemical plant alongside many more chemical, pharmaceutical and water treatment customers.

Extensive Type Testing to Ensure Safety

Our unique bellows manufacturing techniques and design allow us to supply bellows with some of the highest allowable operating pressures. We have conducted extensive product testing on the bellows, having gone through the expensive process of testing many sizes and types of bellows to destruction giving 100% confidence in the data we publish. Along with the relatively straightforward burst testing on a wide array of expansion joints we also enlisted the services of the third party testing house TÜV who over several months getting close on year, conducted slow pressure increase tests at high temperatures to generate comparable real world data taking account of the creep of the PTFE so we can see how the bellows would perform over many years in service.

Large Range of Diameters up to 42”NB!

Our larger bore bellows 28” NB + are usually found in GRP pipelines compensating for thermal expansion and providing a coupling to vessels reducing any forces being applied. Along with ASME 150 series A and series B flanges we also provide flanges to suit ‘J’ bolts commonly used on glass lined reactors. Even with our large diameter expansion bellows we are able to offer these with pressure ratings of 75 psi.

Vacuum Performance

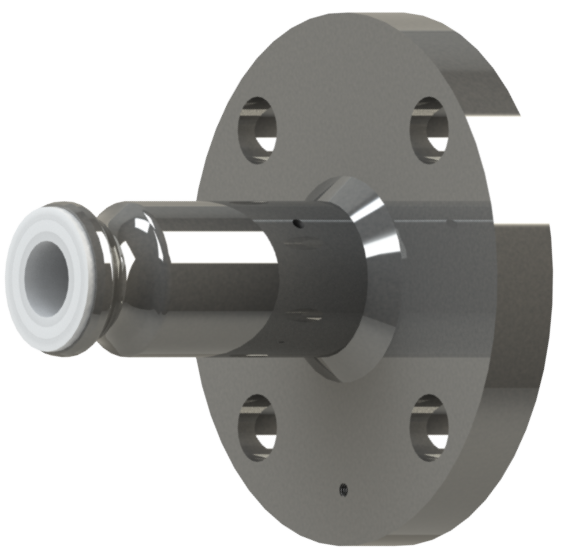

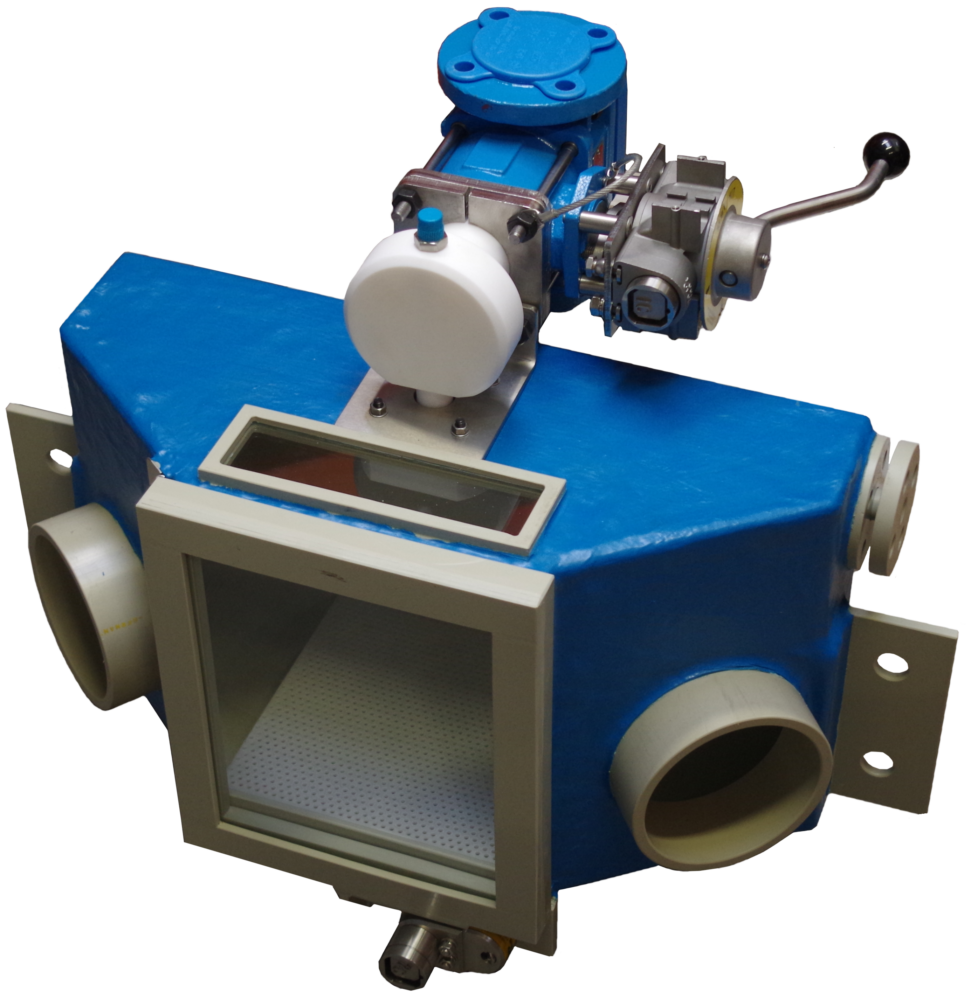

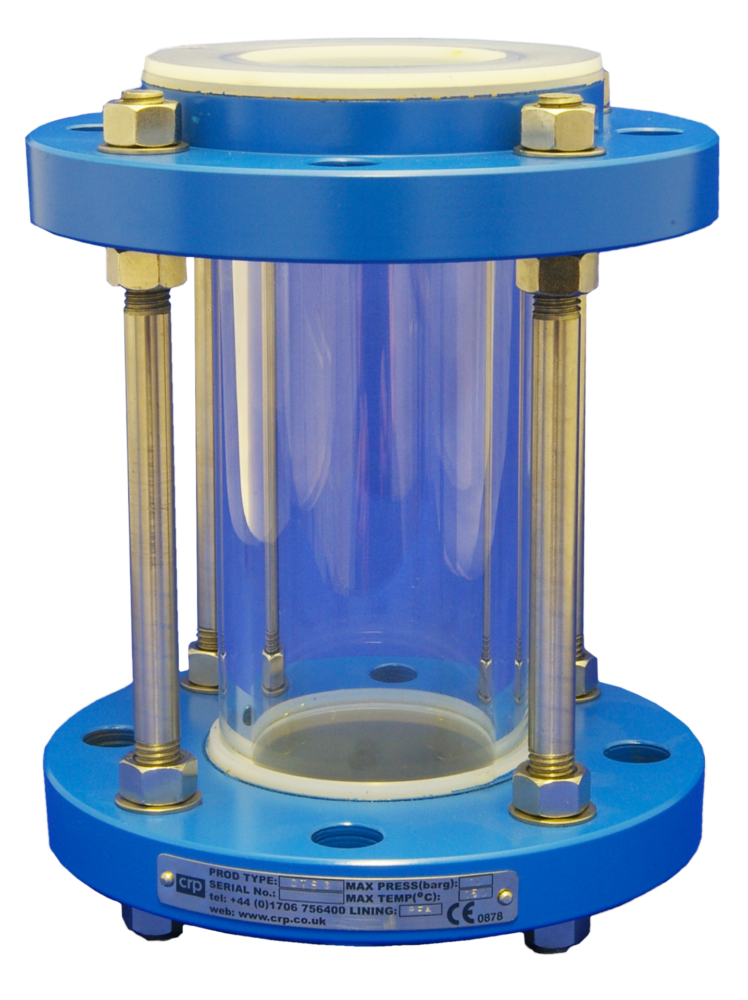

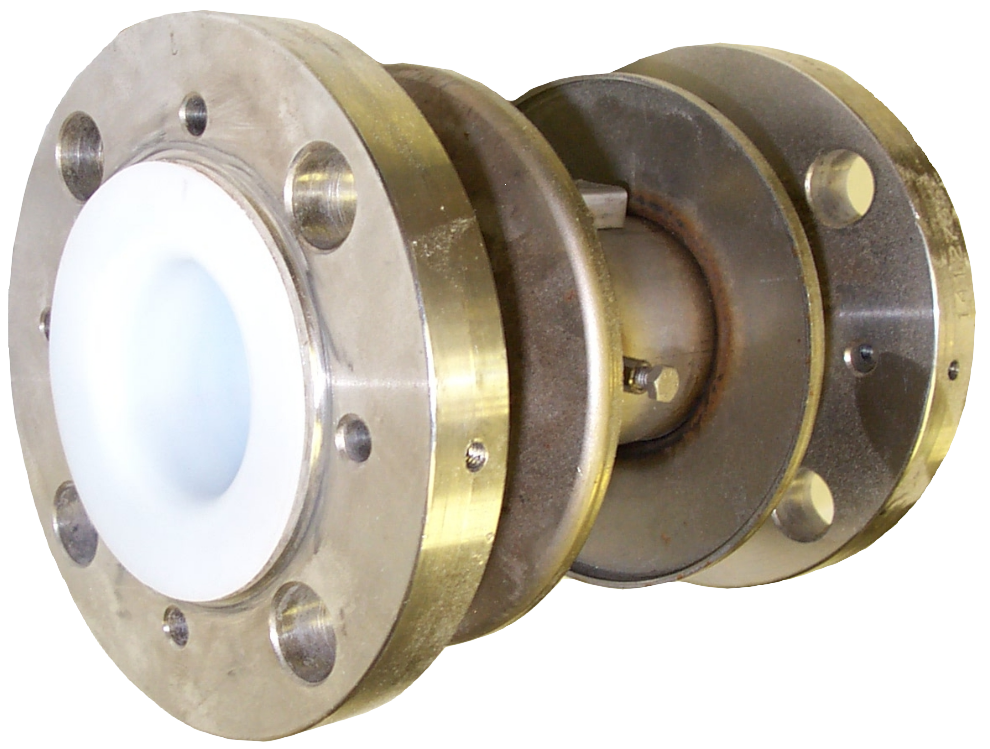

Our smaller sized bellows up to 8”NB are suitable for use under full vacuum right up the maximum bellows temperature rating of 400° F. For larger sizes in our range we can supply the flexible expansion joint with internal metallic vacuum support rings which support the PTFE convolutions, as standard these are PTFE encapsulated stainless steel but we also supply rings produced from tantalum and Hastelloy to suit the customers application.

Unique Manufacturing Technique

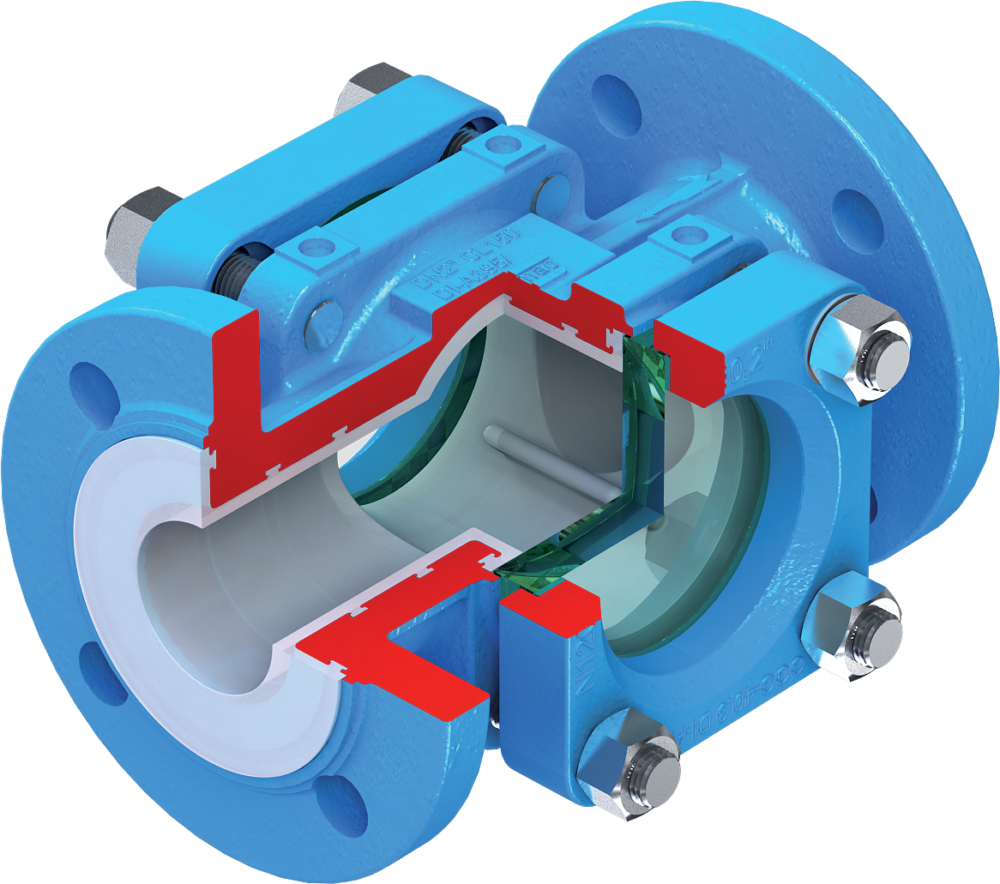

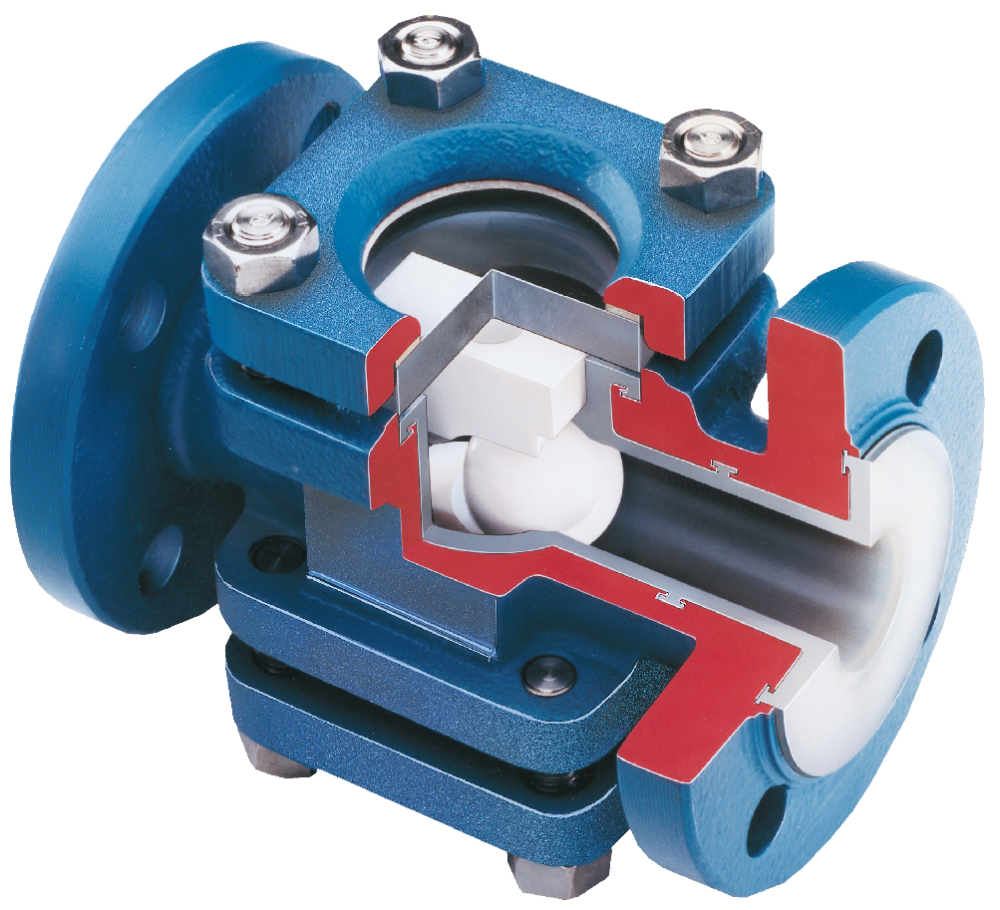

Unlike all others we our manufacturing bellows at very high temperatures and forming the convolutions without using any ‘mould’ type tooling or blowing techniques that thins the liner on the apex of the convolutions. Our bellows are produced to provide a uniform wall thickness which is essential for high pressure ratings and long life. The shape of the bellows is formed without introducing stresses, something that can be easily seen with our bellows where the sealing faces are tightly following the profile of the flat flange and remain so after many years, where with other bellows the flange faces tend to peel away from the flanges and return to a tube state.

Fantastic Corrosion Resistance

PTFE is widely used to convey very corrosive chemicals such as sulphuric and hydrochloric acids. Chemical Producers have relied on the excellent corrosion resistance PTFE for decades. PTFE has some unique properties and the HiPerFlon PTFE liners we produce our expansion joints from are manufactured inhouse allowing full control of the process. PTFE is also FDA approved and more than suitable for integration into water treatment plants, food and pharmaceutical processing and ultra pure applications often found in the semiconductor industries.

Smooth Bore Sleeves

Where bellows are conveying powder and slurries we recommend that a PTFE sleeve flared one end is introduced into the flexible bellows to prevent product building up in the convolutions. The sleeves still allow the required movements in the bellows.

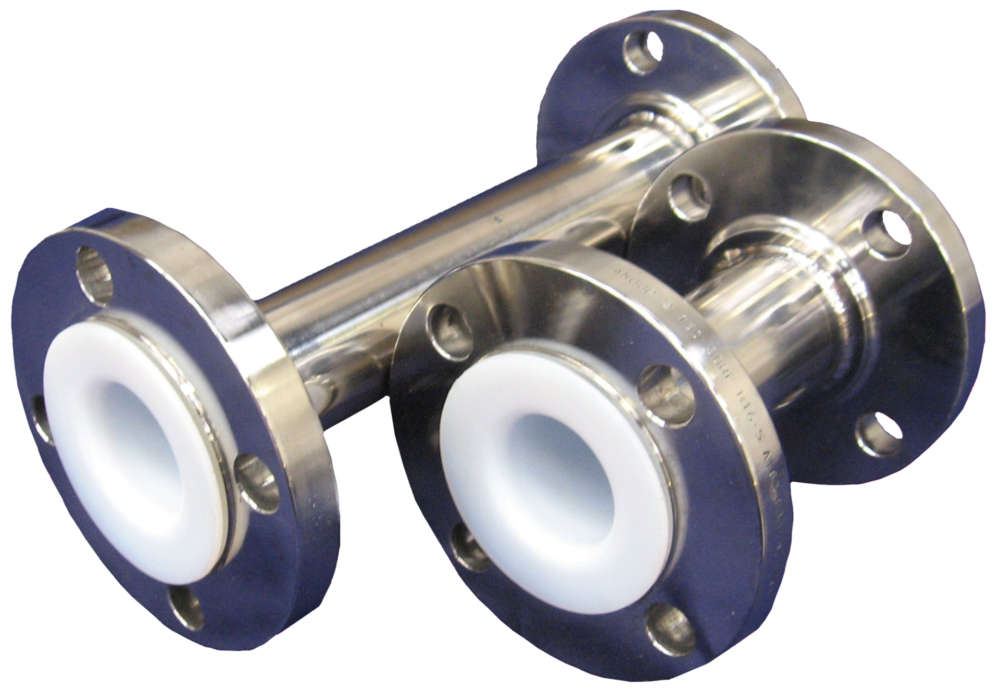

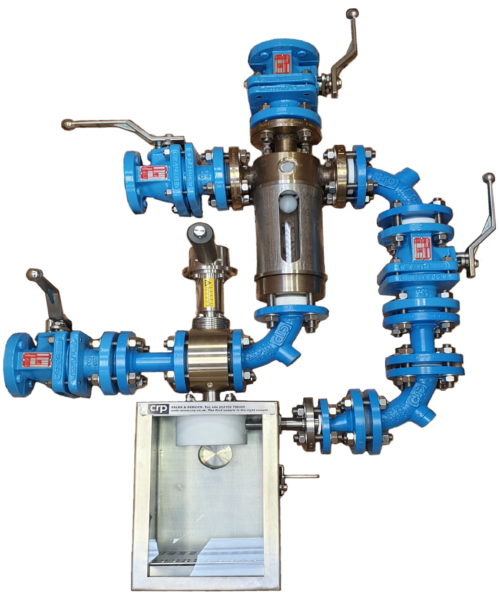

Special Bellows

We supply lots of variations to our bellows, much more than what we can show in our catalog. Reducing bore bellows with different bore sizes of flanges. Universal bellows with a pipe sandwiched between two bellows provide much larger lateral movements. Hinged bellows that completely limit lateral and axial movement solely allowing angular movement only. Lateral bellow with sets of spherical washers limiting axial and angular movement and so on.

https://www.crp-us.com/wp-content/uploads/2020/brochures/Brochure%20-%20Bellows.pdf

For more information download our catalog or contact us