Biodiesel production often involves a number of energy generation processes, with its promise of cleaner alternatives and reduced environmental impact. At the forefront of this intricate process is Corrosion Resistant Products (CRP), offering innovative solutions that redefine industry standards. Step into a world where the commitment to excellence converges with environmental stewardship, exploring the intricacies of biodiesel production and the pivotal role CRP plays in this transformative journey.

Understanding the Biodiesel Production Industry

Biodiesel, heralded as a renewable and eco-friendly alternative to traditional fossil fuels, is central to the ongoing global shift towards sustainable energy sources. In the intricate world of biodiesel production, where precision, reliability, and durability are paramount, CRP navigates the intricacies with a deep understanding of the industry’s demands.

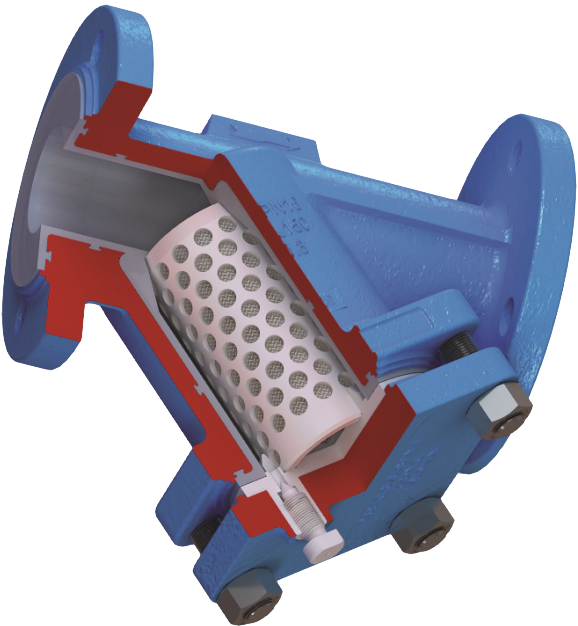

From feedstock selection and transesterification processes to the intricate filtration systems that purify the end product, every facet of biodiesel production demands materials that can withstand corrosive environments and ensure longevity. CRP’s expertise lies not just in providing products but in comprehending the nuanced requirements of biodiesel production businesses.

How We Serve Biodiesel Production Businesses

Our goal at Corrosion Resistant Products (CRP) is to be a true partner in the success of biodiesel production companies, going above and beyond simply providing materials.

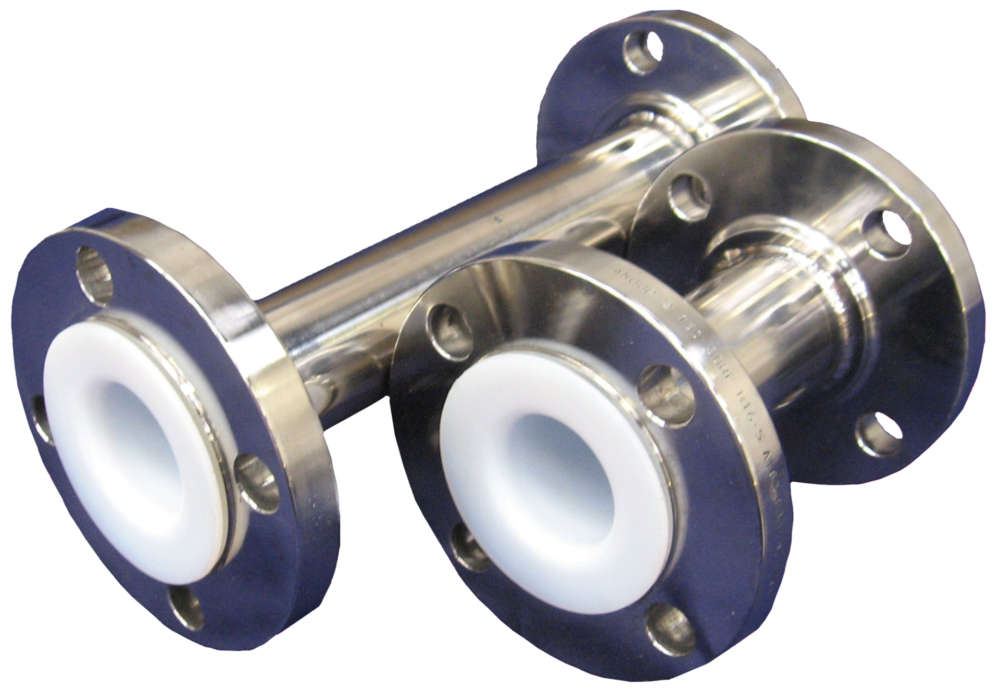

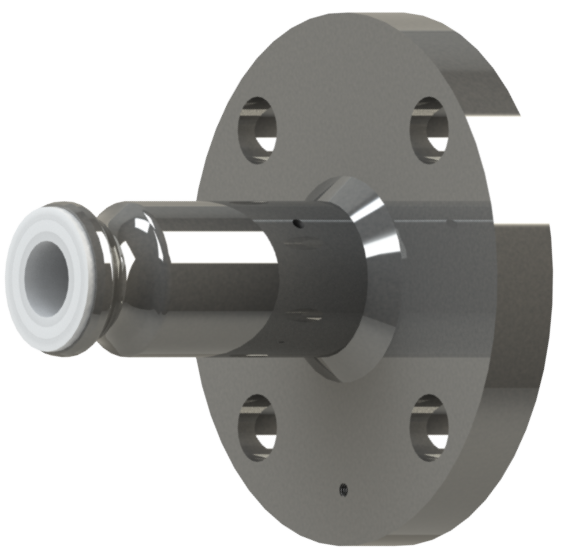

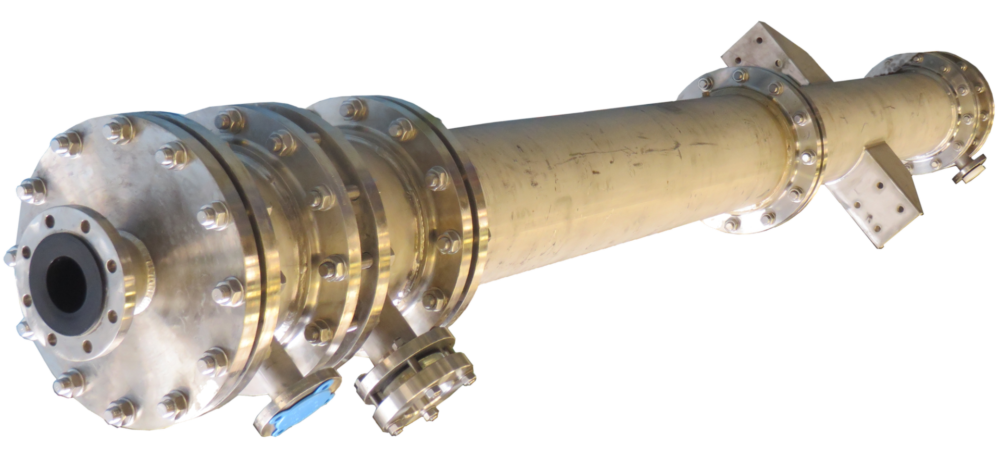

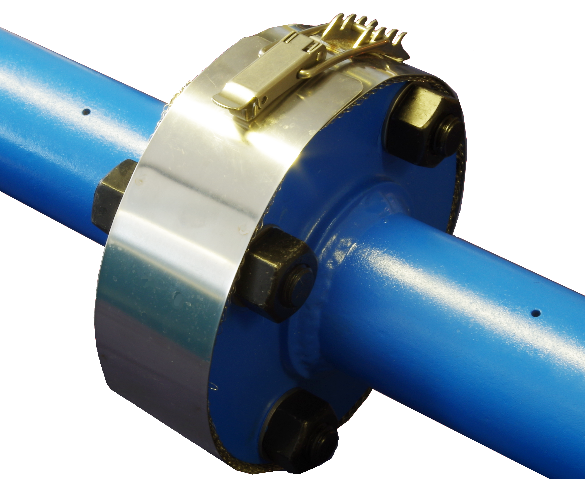

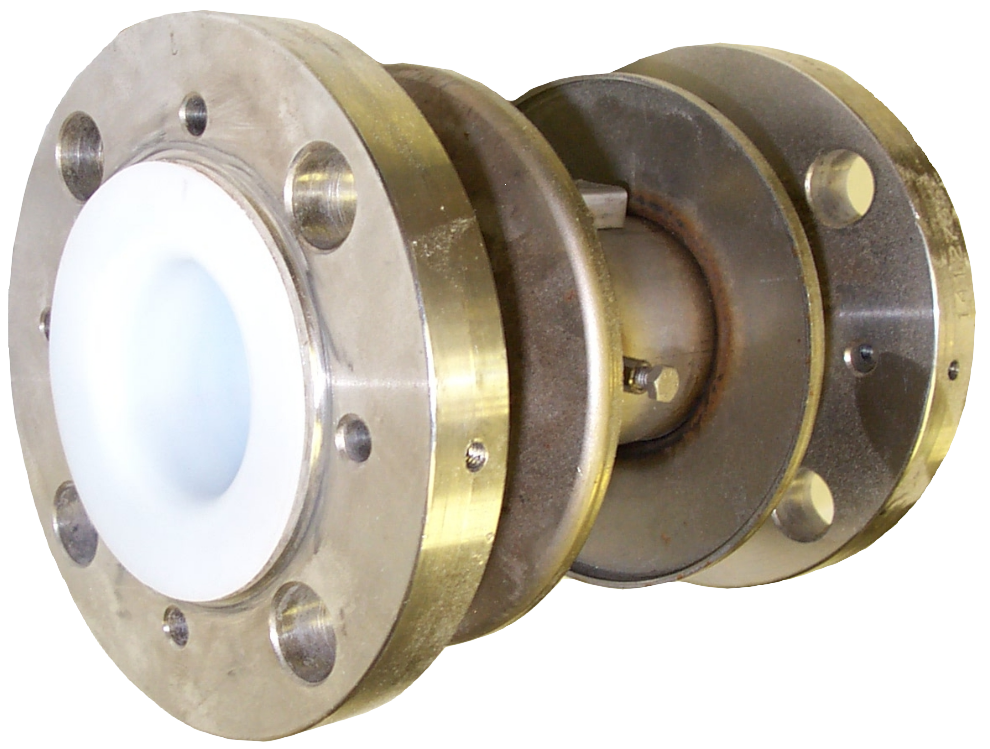

- Lined Piping: Our PTFE/PFA lined piping ensures the integrity of biodiesel production processes by offering superior resistance to corrosion and chemical degradation.

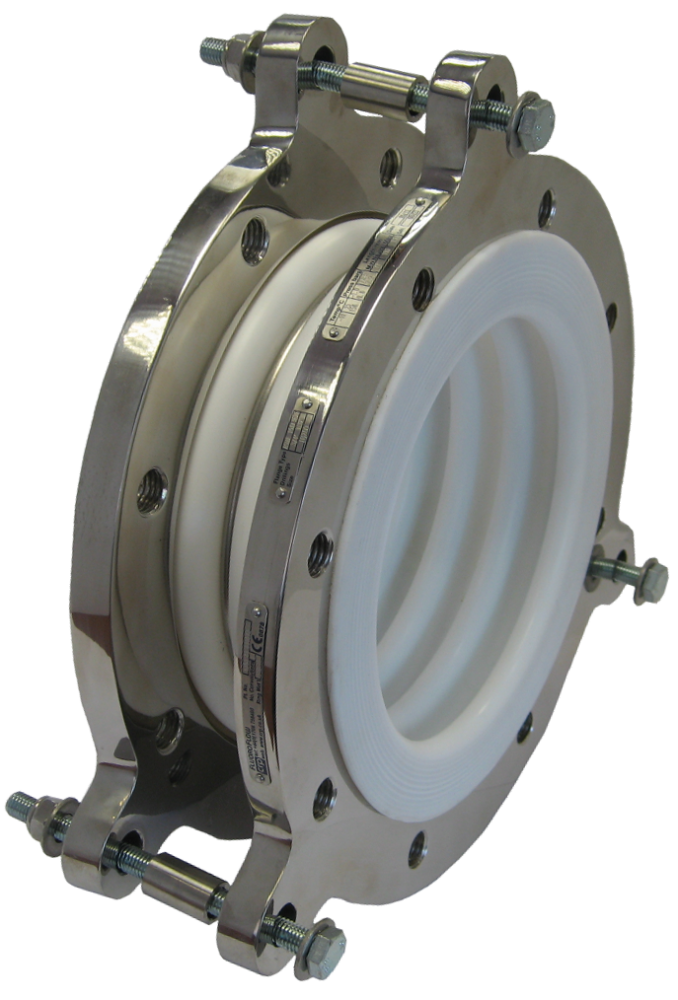

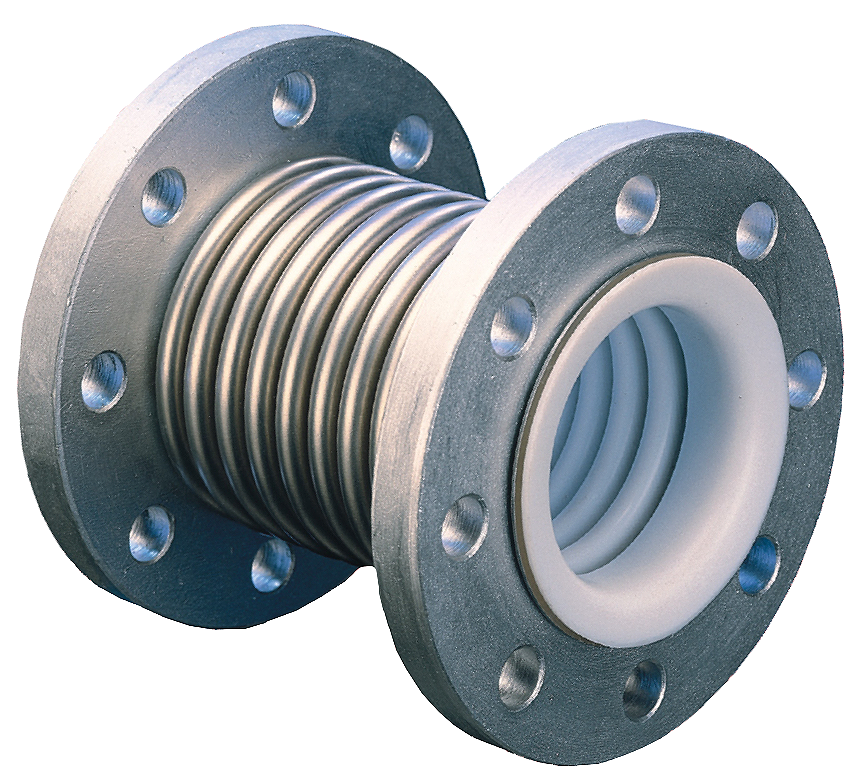

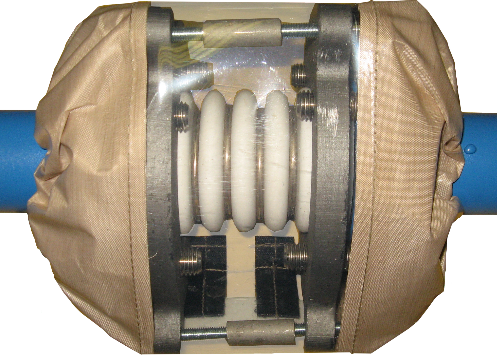

- Bellows: Providing flexibility and vibration absorption, CRP’s bellows solutions enhance the reliability and lifespan of piping systems in the biodiesel industry.

- Columns: Tailored for biodiesel purification and separation processes, our columns optimize production efficiency and maintain high-quality output.

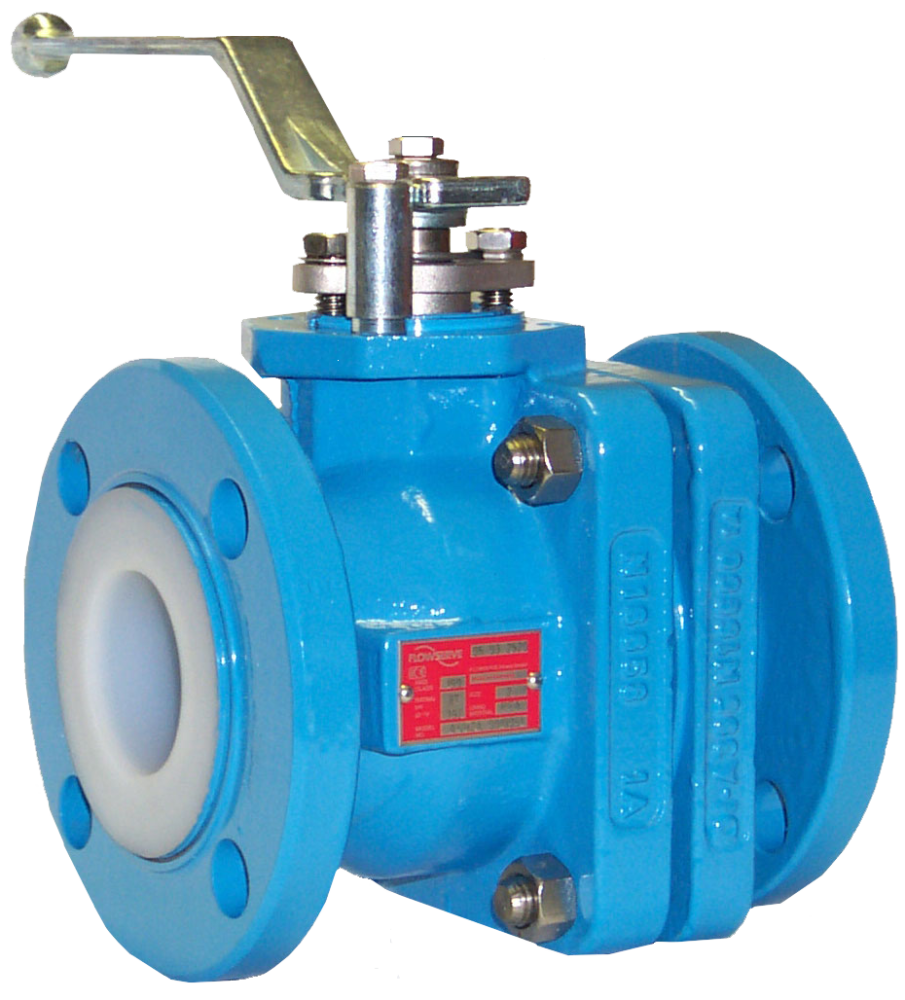

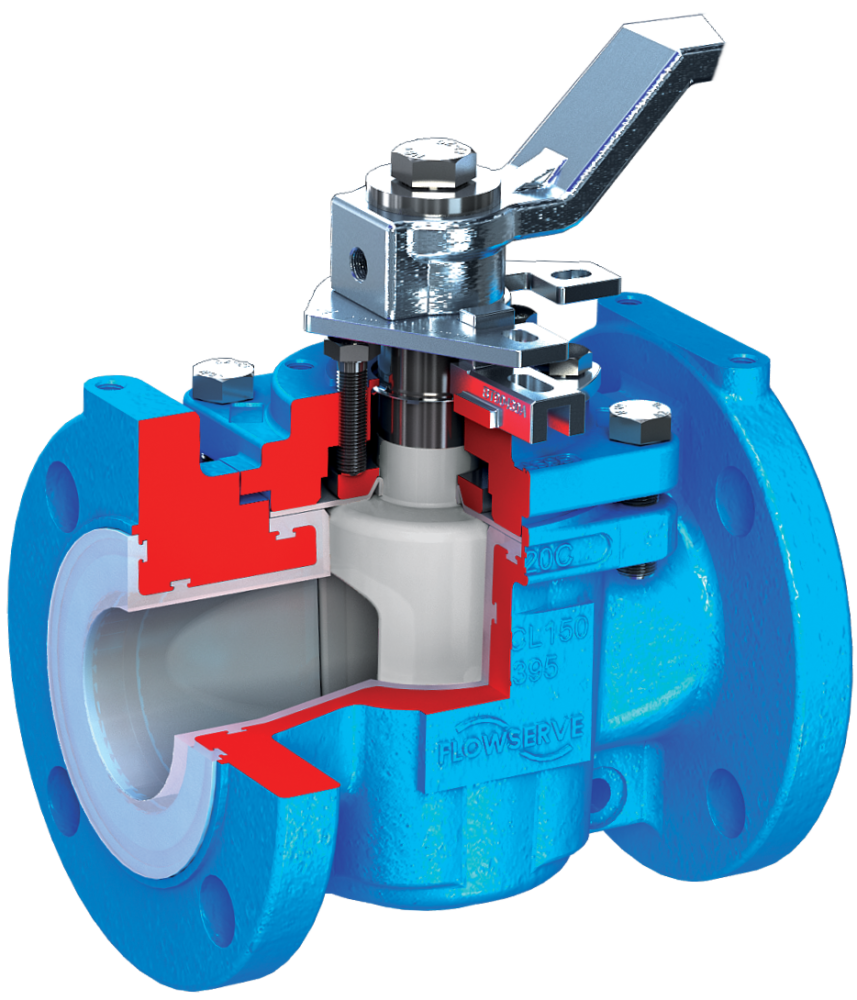

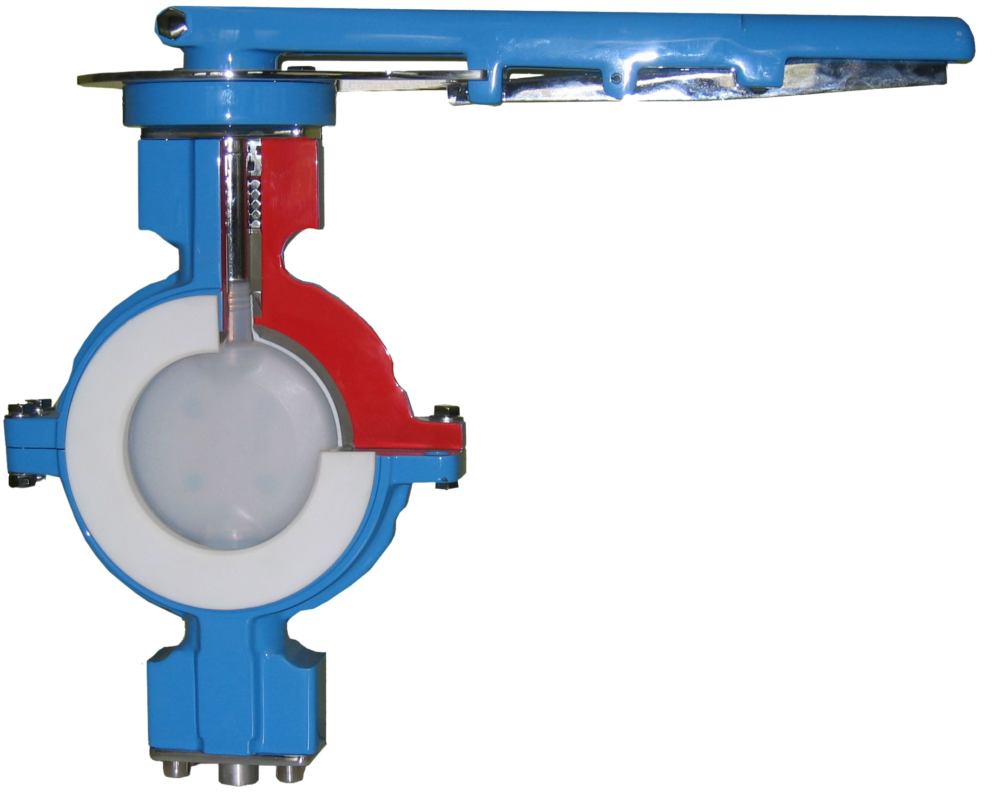

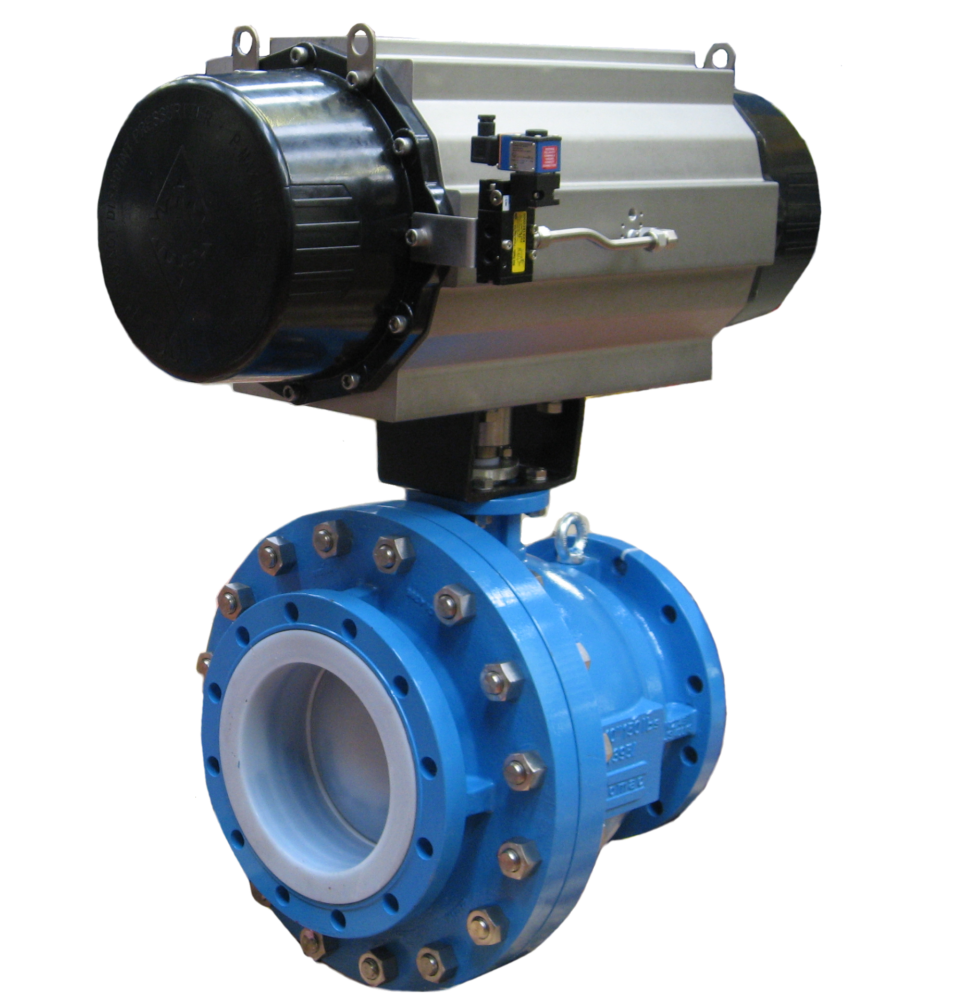

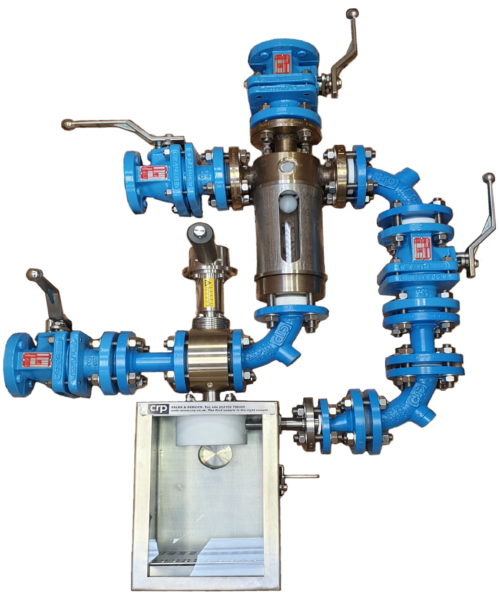

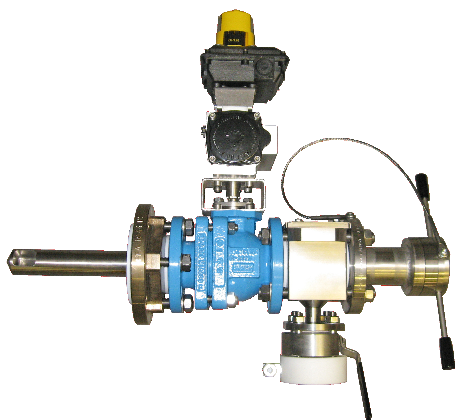

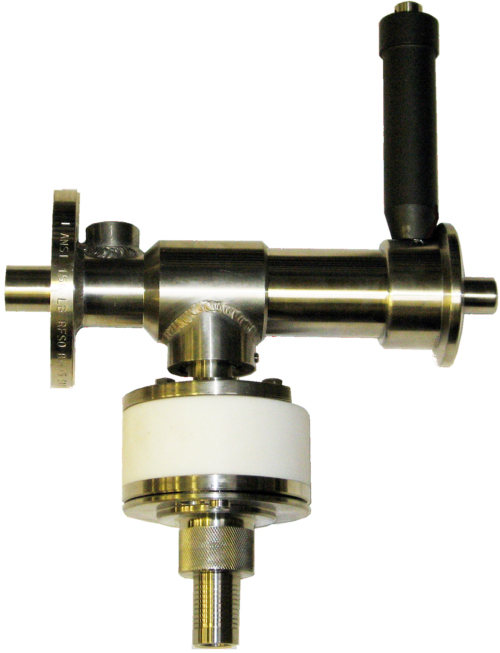

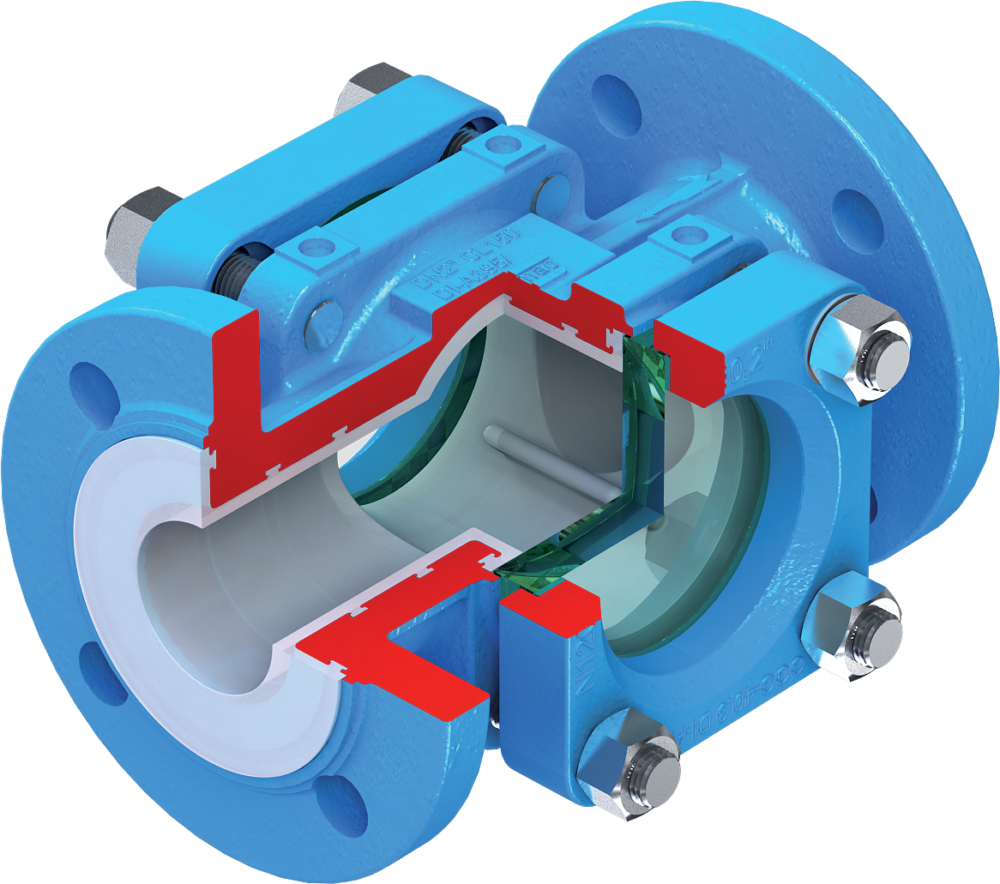

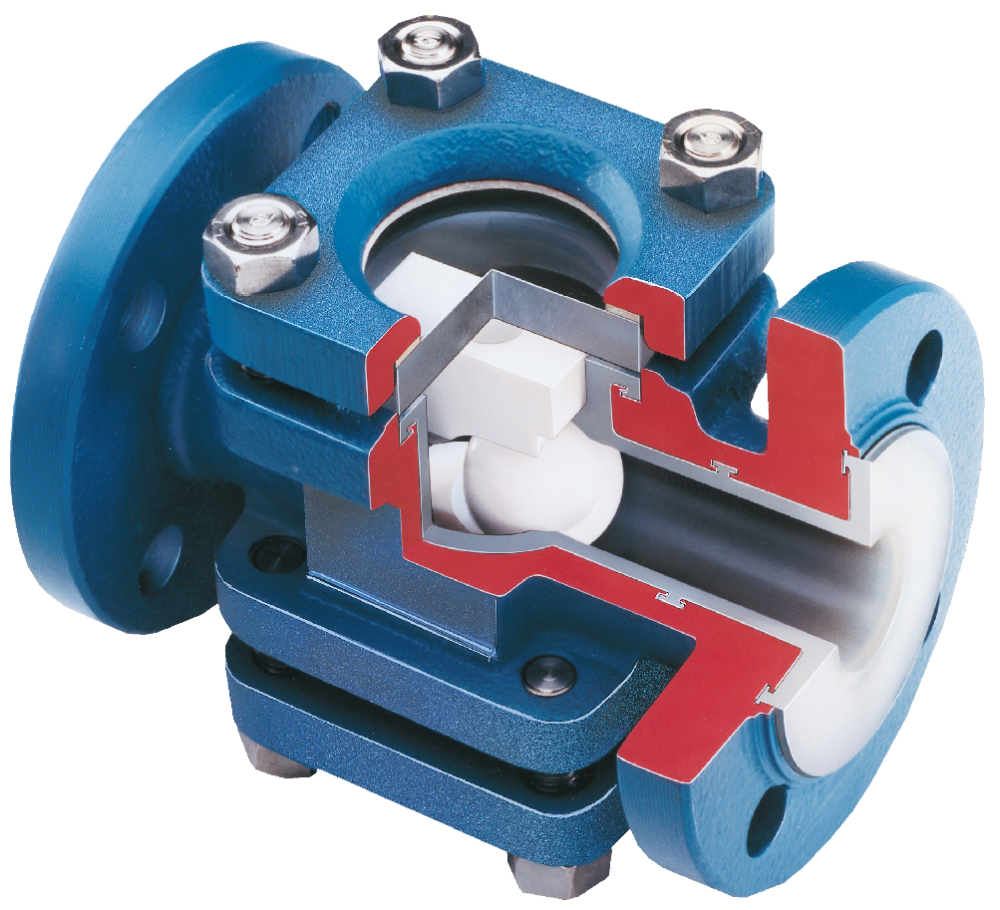

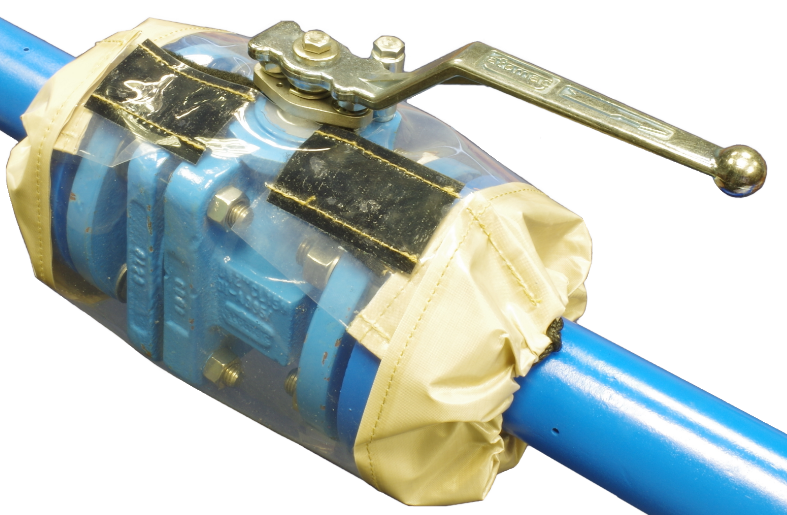

- Valves: These specialized valves facilitate precise control of fluid flow in biodiesel production, ensuring accurate and efficient processing.

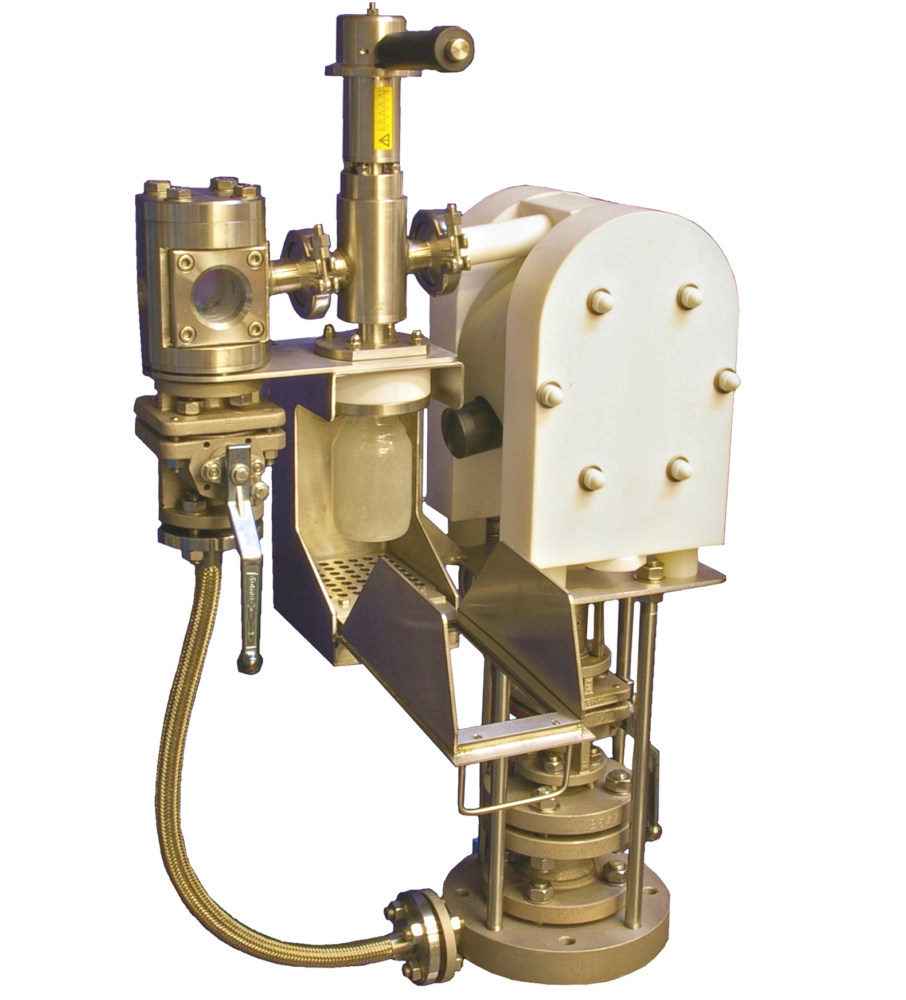

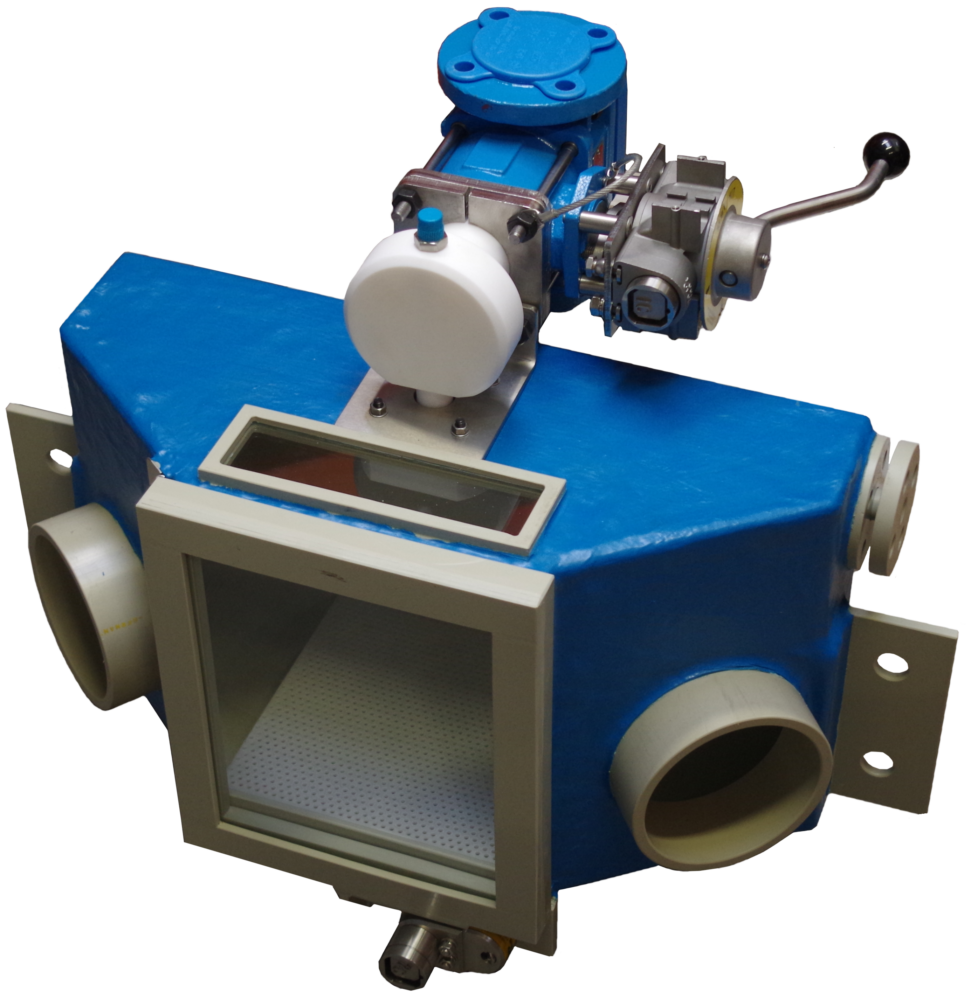

- Sampling Systems: Designed for reliable sample collection, CRP’s systems support quality control and compliance in the biodiesel manufacturing process.

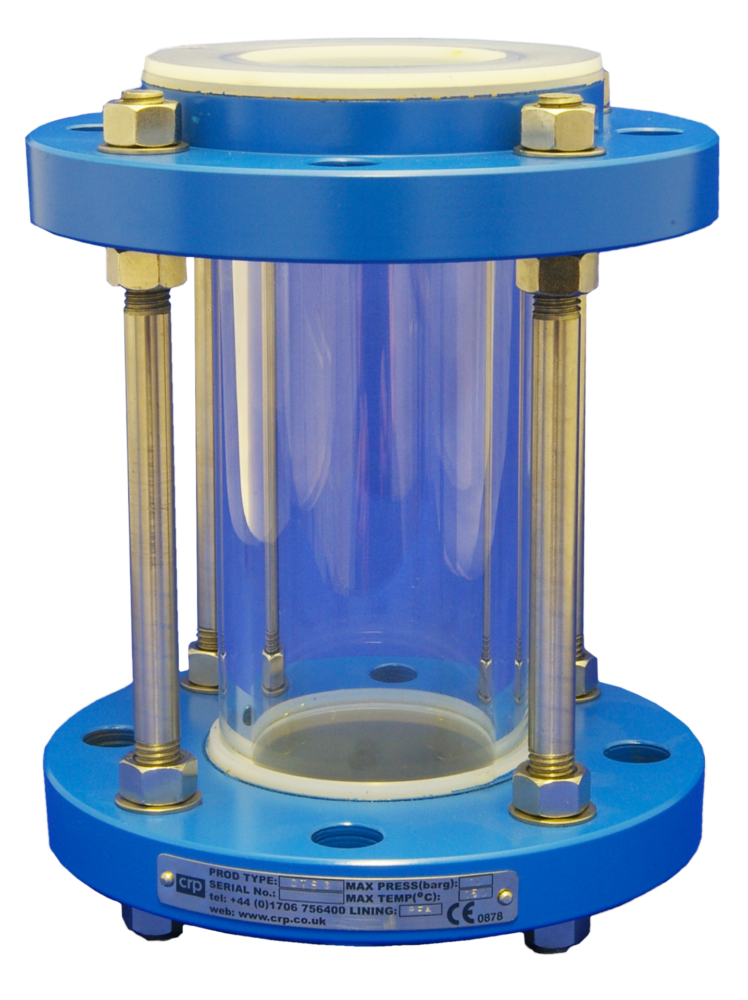

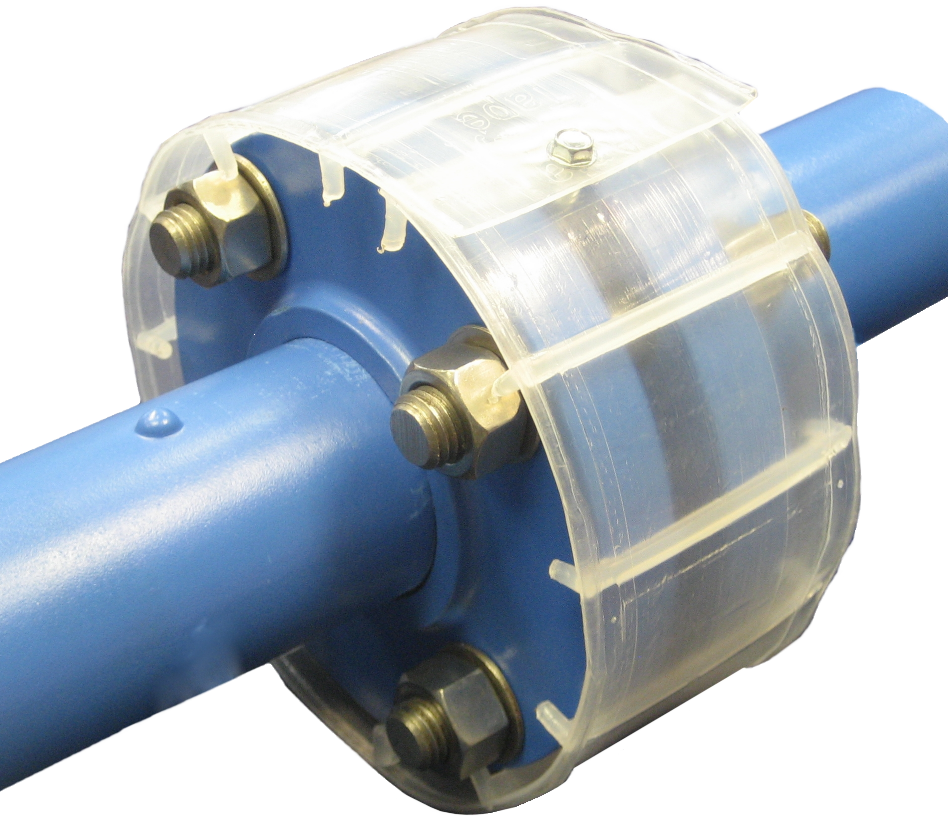

- Sight Glasses & Gauges: Offering transparency and accurate measurement, our sight glasses and gauges contribute to effective monitoring and control of biodiesel production.

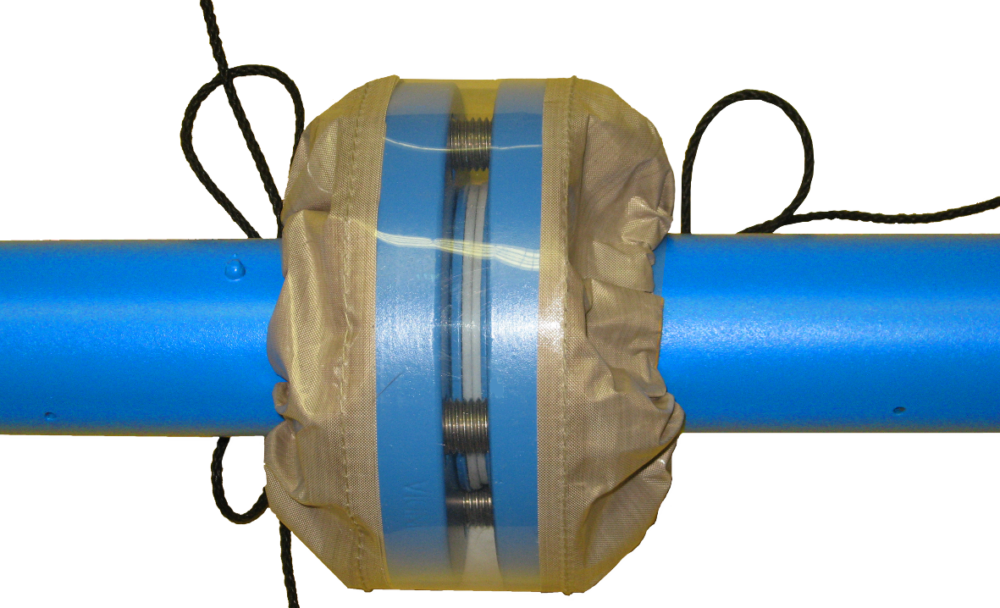

- Safety Shields: Enhancing workplace safety, our safety shields protect personnel and equipment from potential hazards, ensuring a secure environment for biodiesel production.

Why Is CRP the Right Partner for PTFE / PFA Lined Piping Solutions?

Corrosion Resistant Products (CRP) stands as the ideal partner for PTFE and PFA lined piping solutions for several compelling reasons. Firstly, our technical expertise sets us apart in the industry. With a team of seasoned professionals possessing in-depth knowledge of corrosion-resistant materials and their applications, CRP ensures that our PTFE and PFA lined piping solutions meet and exceed the stringent standards of the biodiesel production industry.

Secondly, our commitment to customization and adaptability makes us the preferred partner for biodiesel production businesses. We understand that each production setup is unique, and our PTFE and PFA lined solutions are designed with flexibility in mind. Whether clients require specific configurations, sizes, or features, CRP delivers tailored solutions that seamlessly integrate into diverse production environments. By combining technical prowess with a commitment to personalized service, CRP emerges as the right partner for biodiesel production businesses seeking reliable, adaptable, and high-performance PTFE and PFA lined piping solutions.

For more information about PTFE / PFA lined piping solutions for Biodiesel Production businesses, do not hesitate to contact us today.