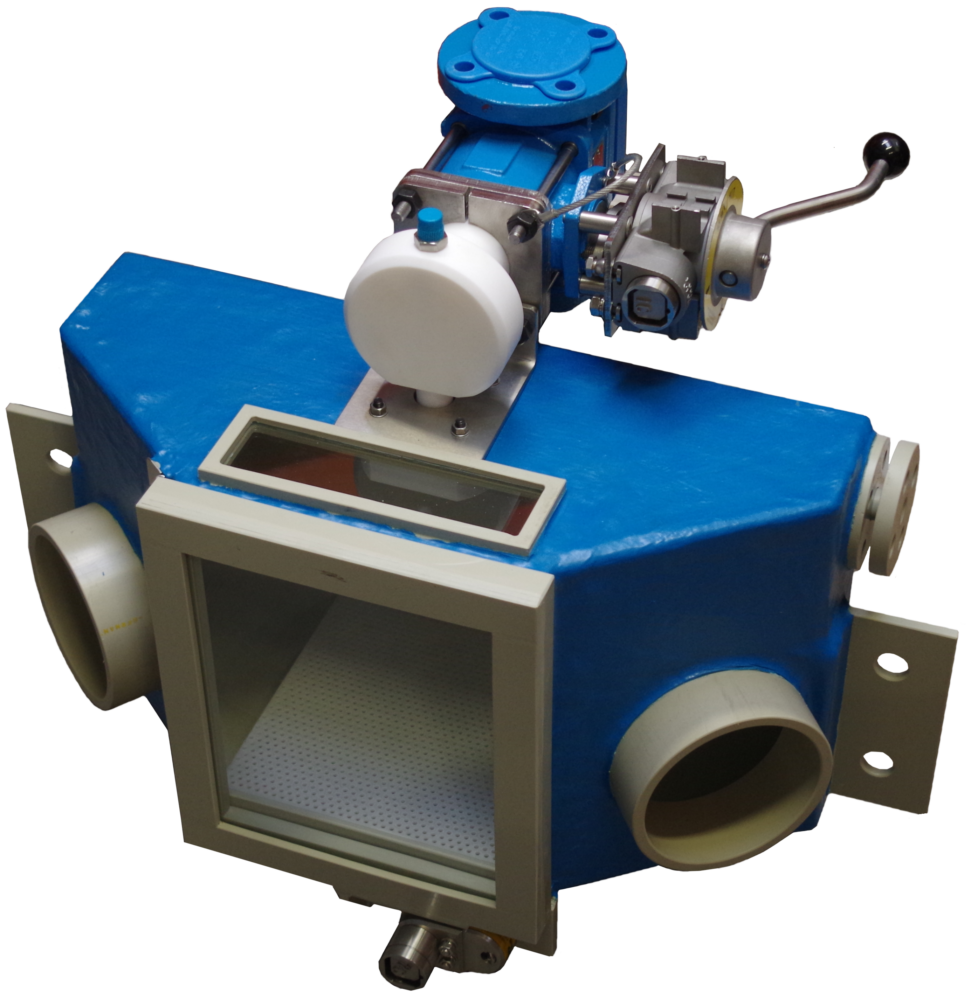

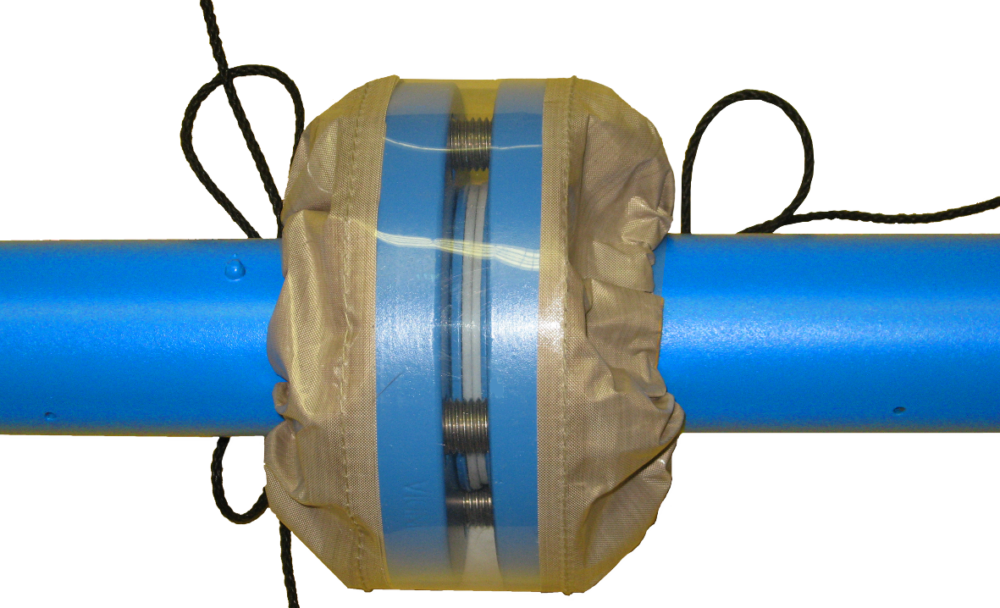

Industrial processes often need the right solution, and understanding the materials and components is key to withstanding harsh environments. Corrosion is a formidable challenge in many applications, causing damage and necessitating frequent maintenance. At the heart of fighting corrosion are the types of pipe fittings designed to endure harsh chemicals and temperatures.

Corrosion Resistant Products Ltd. confronts corrosion with a wide product range. We specialize in PTFE linings and PFA molded fittings with products that promise longevity and reliability. We also train on-site teams on the production and maintenance of PTFE-lined piping, helping fight corrosion.

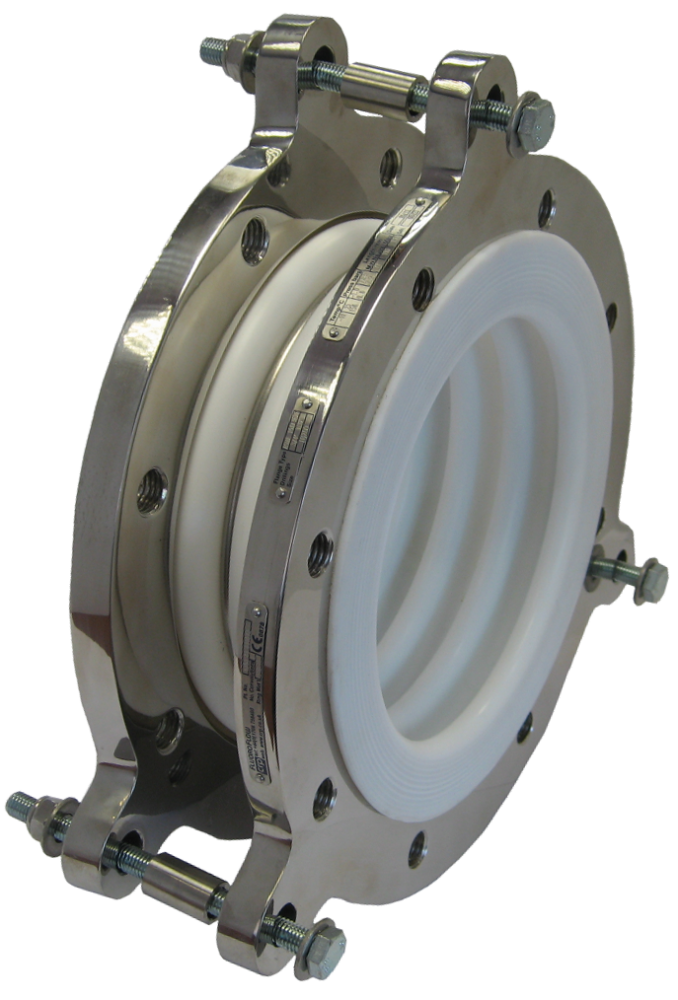

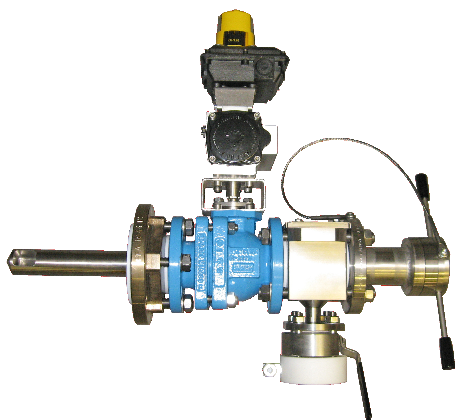

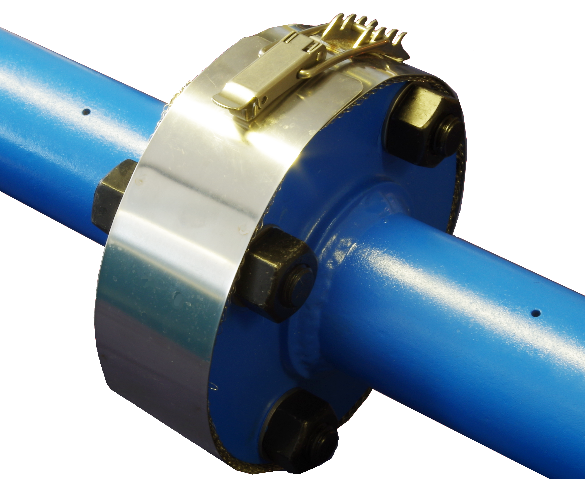

ASME Fittings

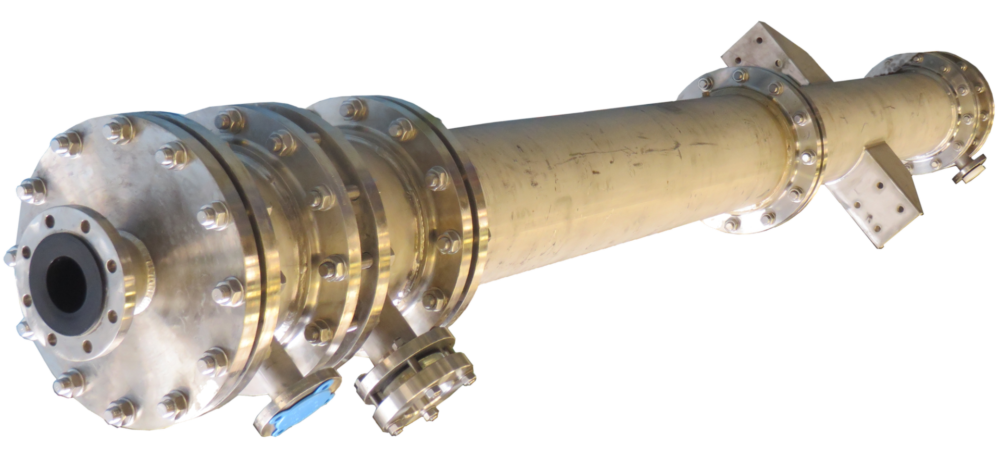

American Society of Mechanical Engineers (ASME) fittings are renowned for their high-quality standards, crucial in applications where safety and efficiency matter. These fittings come in various shapes and sizes, designed to match the demanding needs of multiple industries, from oil and gas to power generation.

One notable feature of ASME fittings is their ability to withstand high pressures. They’re made from materials that can handle high and low temperatures, making them versatile. Manufacturers must adhere to strict guidelines to label their products as ASME compliant, ensuring each piece meets the rigorous requirements for durability and performance.

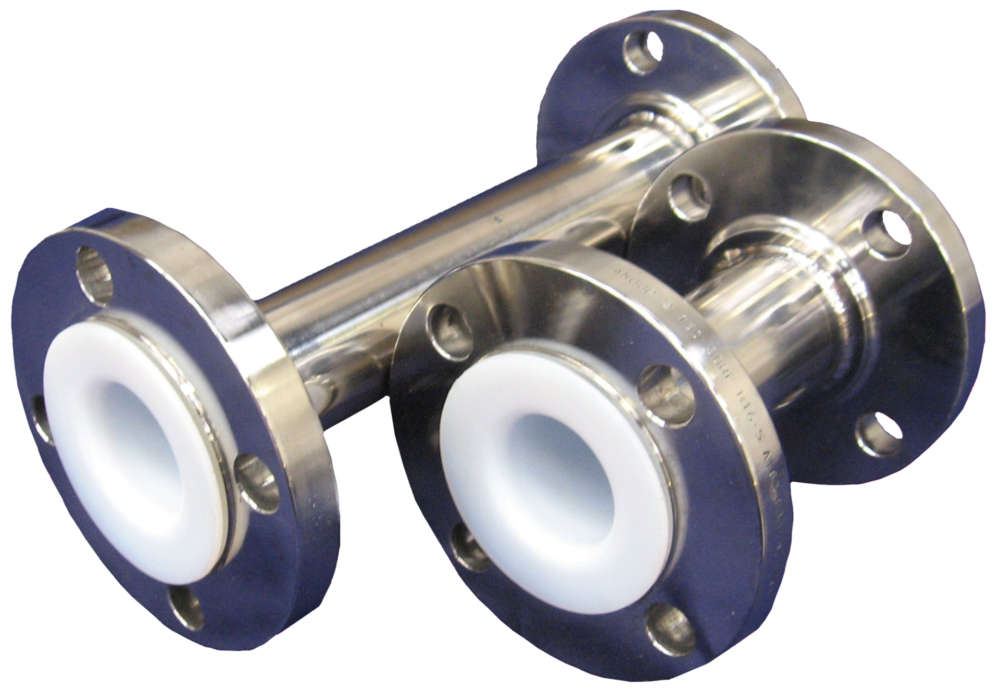

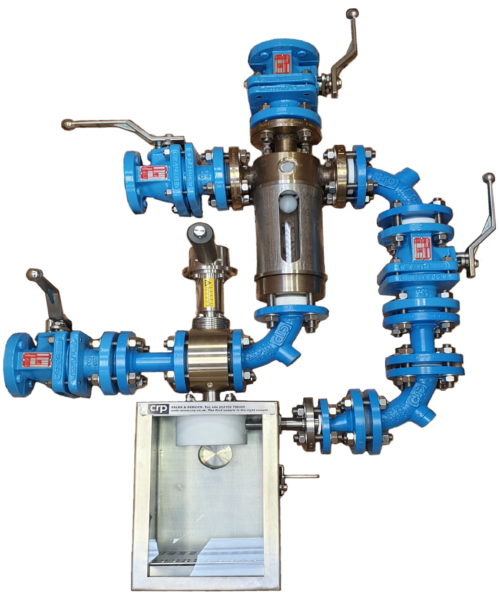

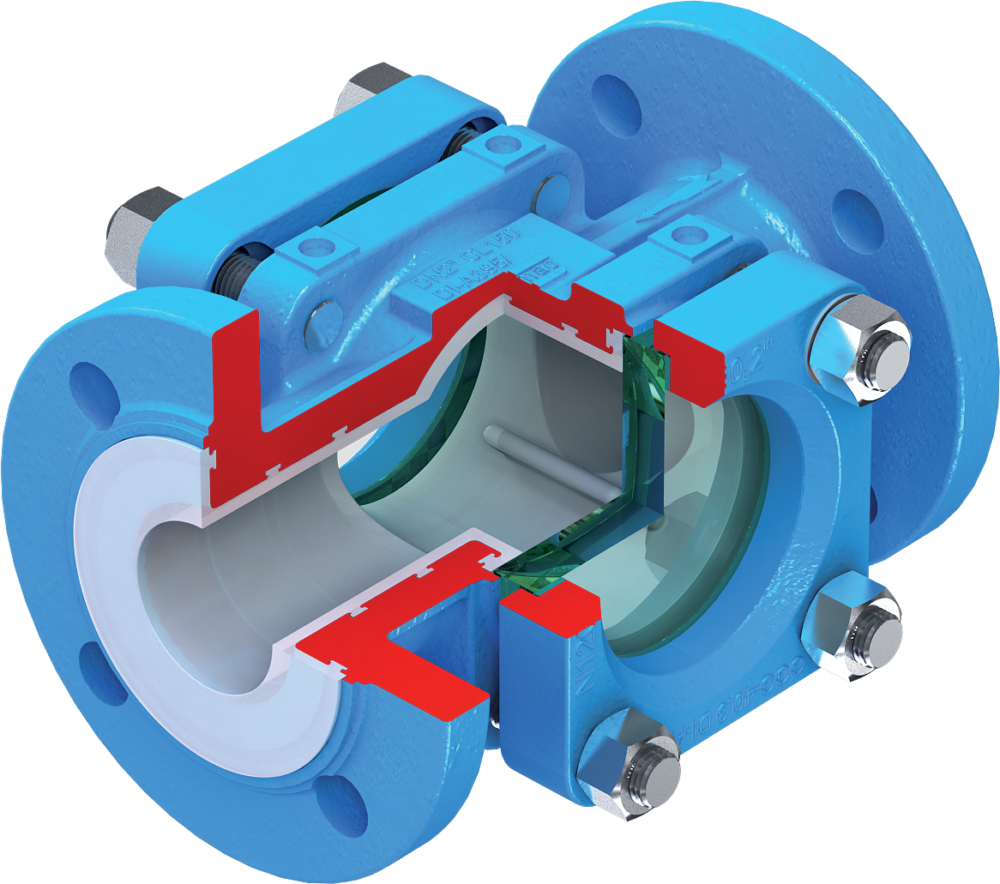

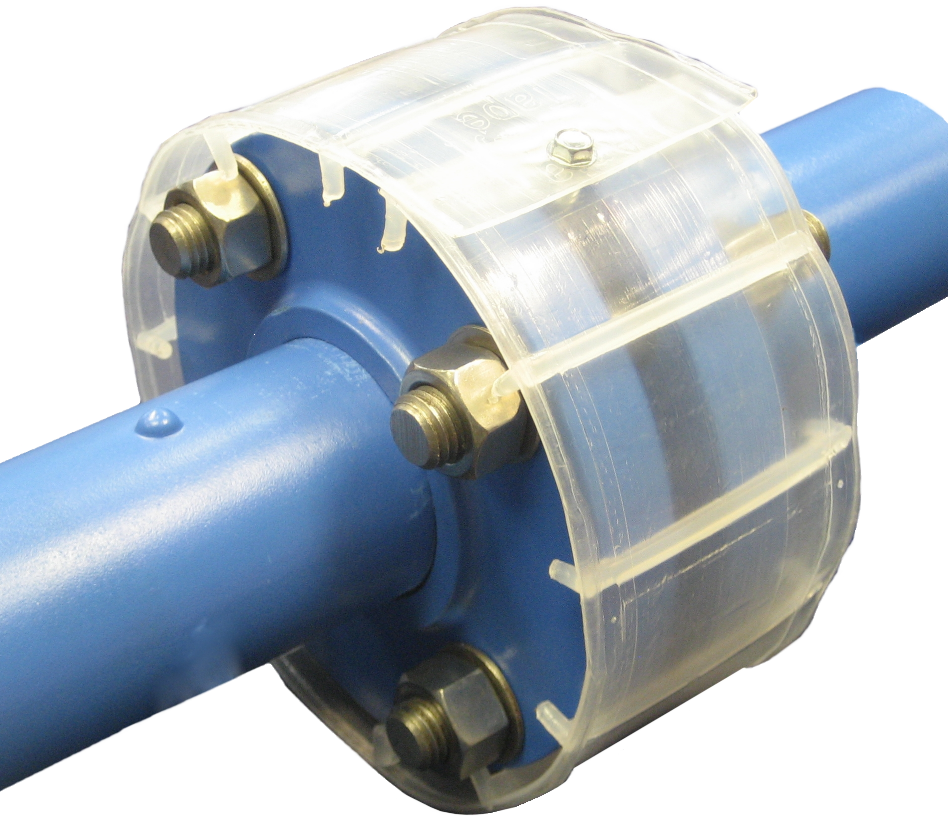

DIN Fittings

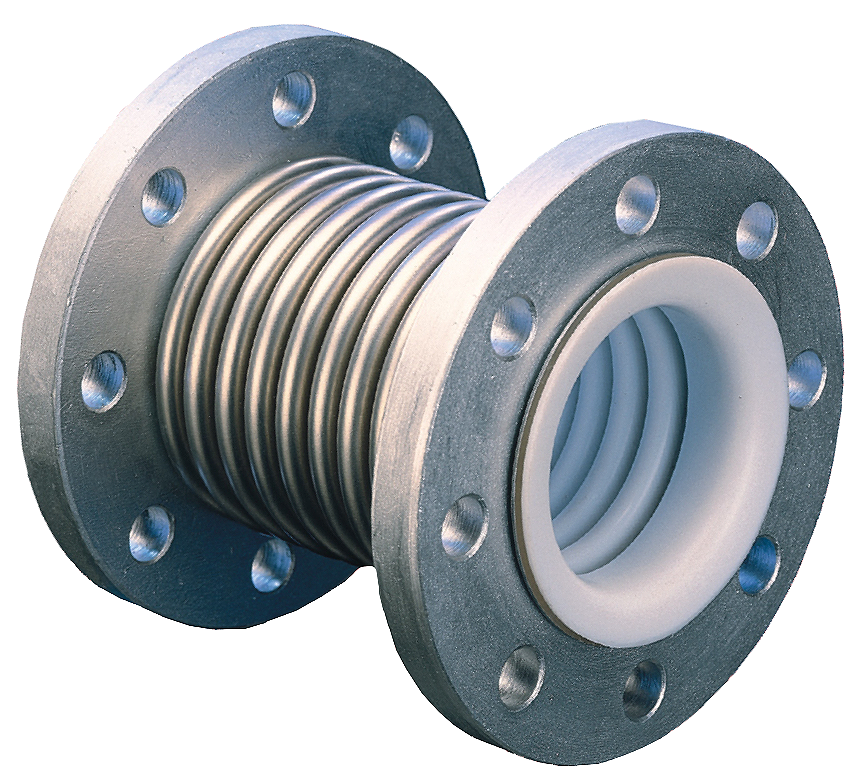

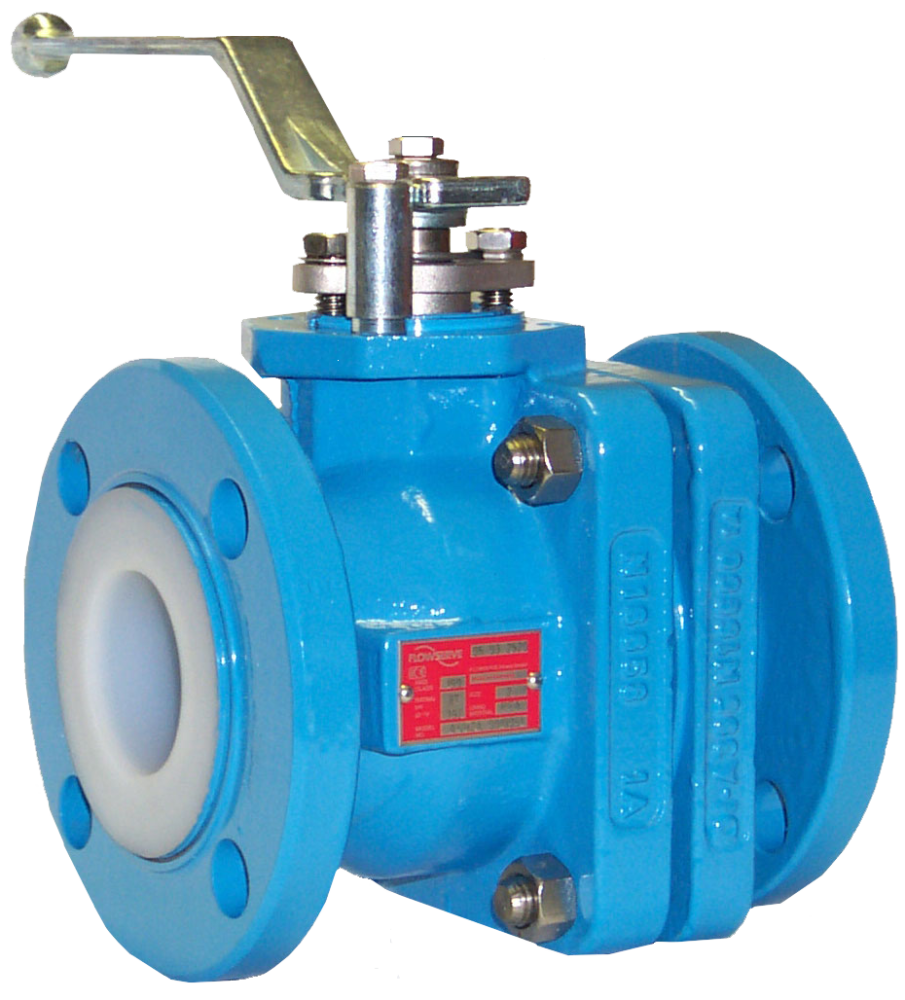

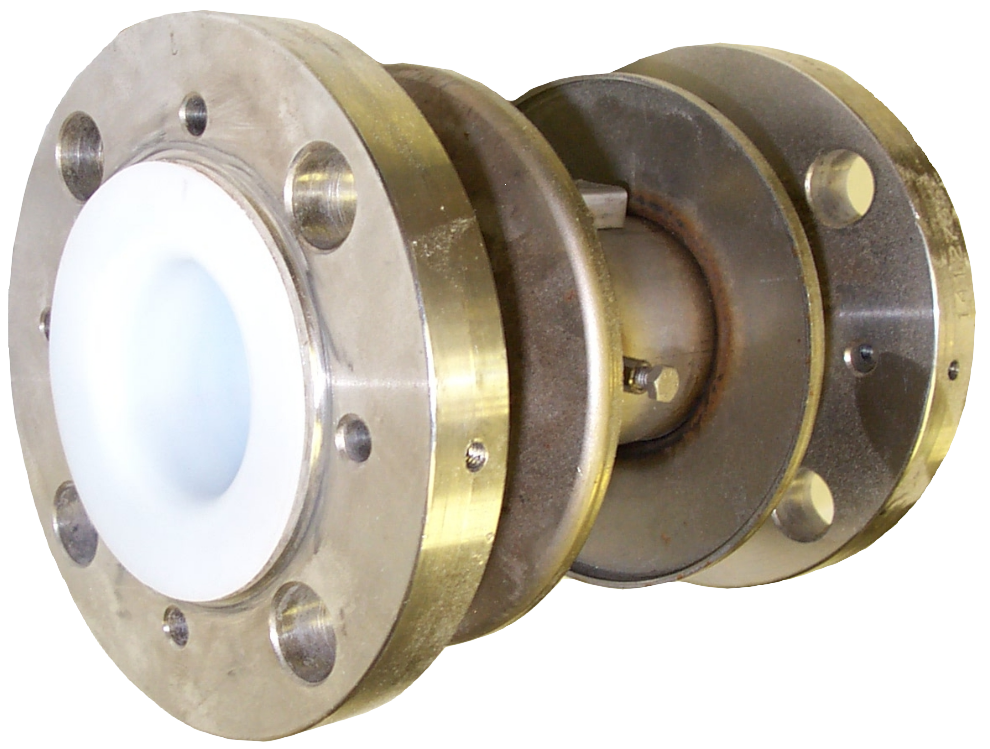

DIN fittings, governed by the German Institute for Standardization, are known for their precision and reliability. They are widely used across Europe and have gained popularity worldwide for their high-quality standards. Like ASME fittings, DIN fittings come in many shapes, sizes, and materials, catering to various applications.

The defining characteristic of DIN fittings is their tight seal, which is paramount in preventing leaks and maintaining system integrity. They are ideal for systems requiring accurate alignment and a robust connection, embodying reliability and efficiency. Their compatibility with other standards makes them a favored choice in global projects, showcasing versatility and precision.

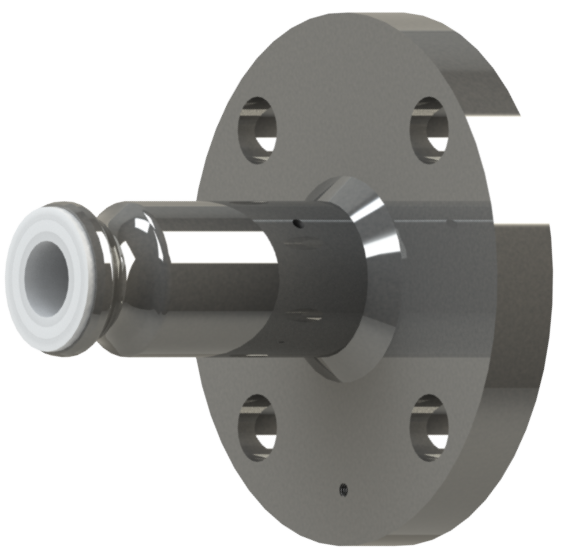

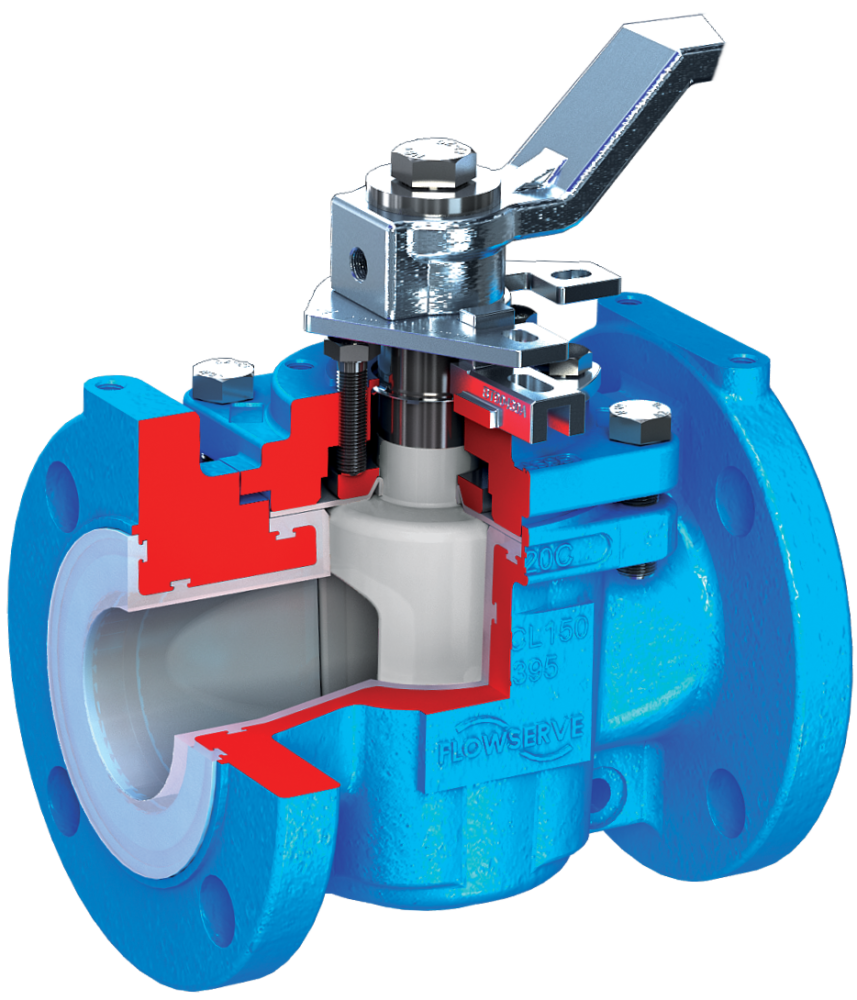

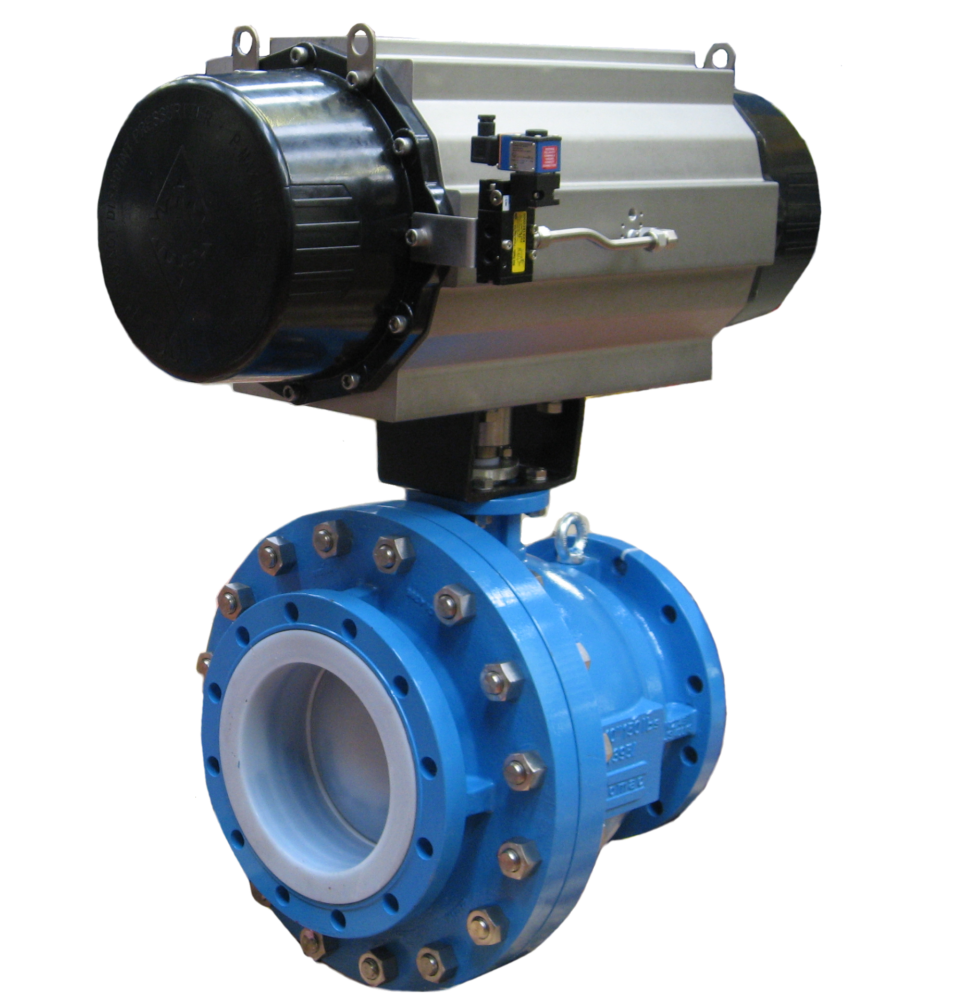

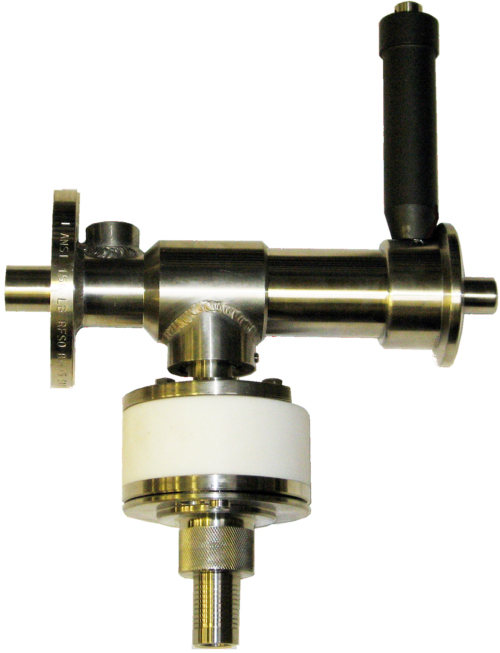

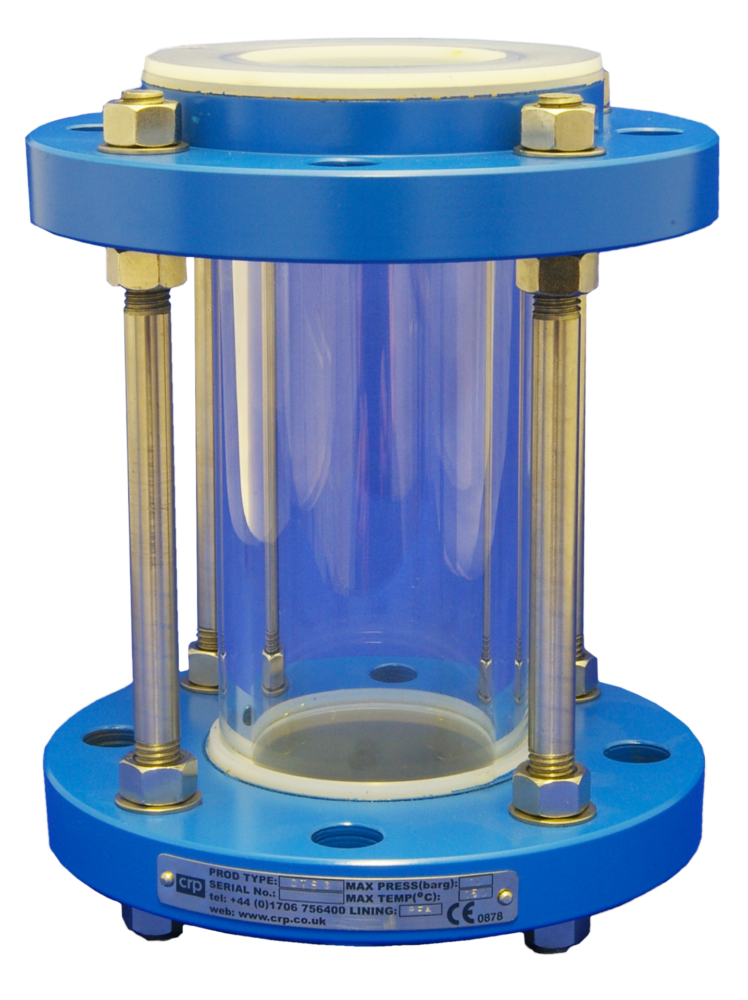

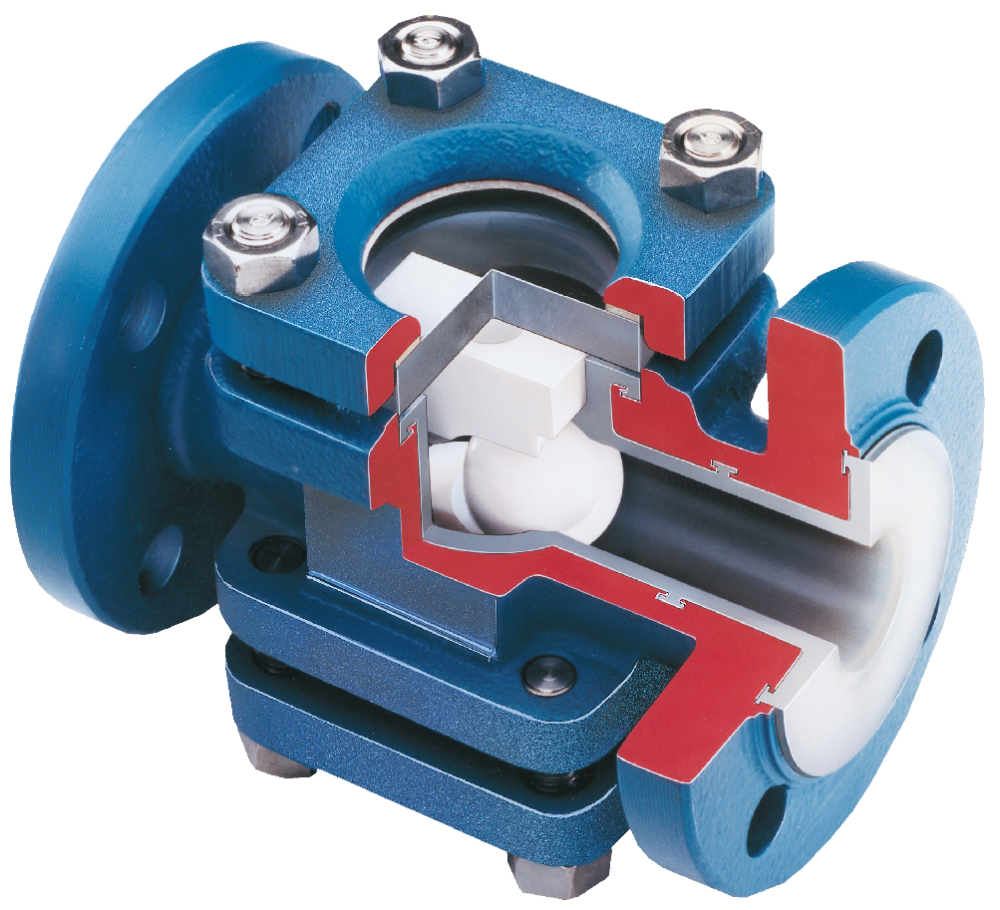

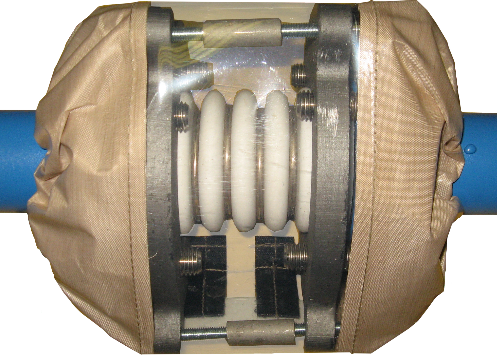

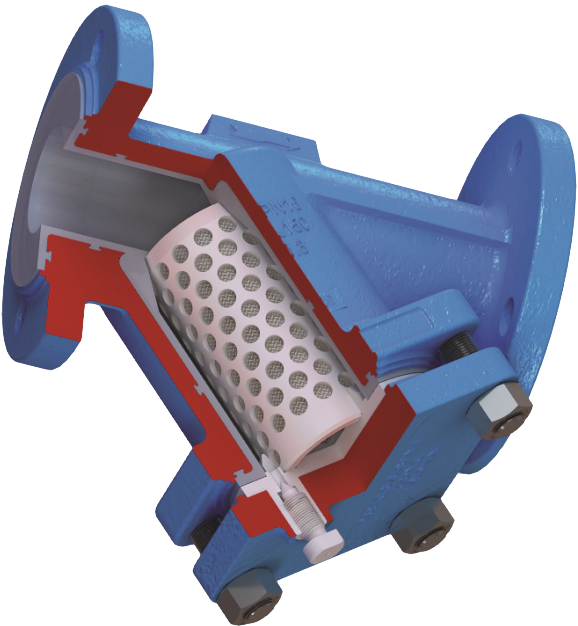

PFA Molded Fittings

Perfluoroalkoxy (PFA) molded fittings stand out for their exceptional chemical resistance, making them suitable for handling corrosive substances. These fittings are crafted using a molding process that ensures uniformity and quality, essential for their application in chemical processing industries.

The major advantage of PFA fittings is their ability to maintain integrity in extreme conditions. They can withstand various temperatures, from very cold to hot, without degrading. This makes them a durable option for systems that encounter a variety of substances and conditions, guaranteeing a reliable seal and longevity.

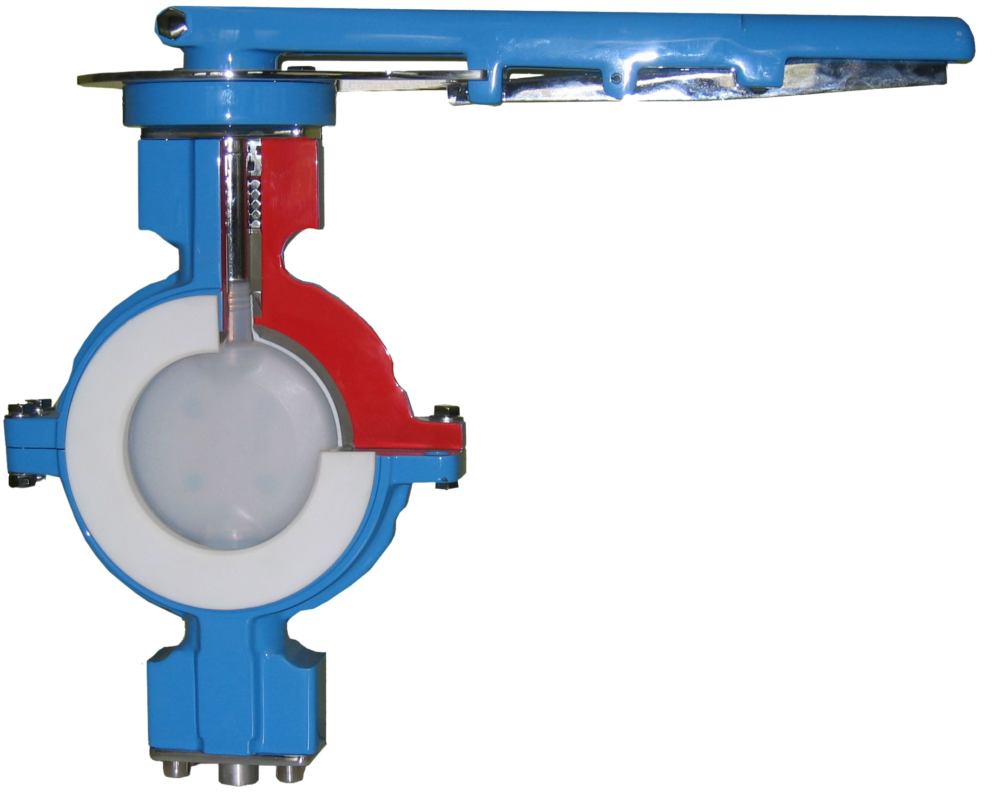

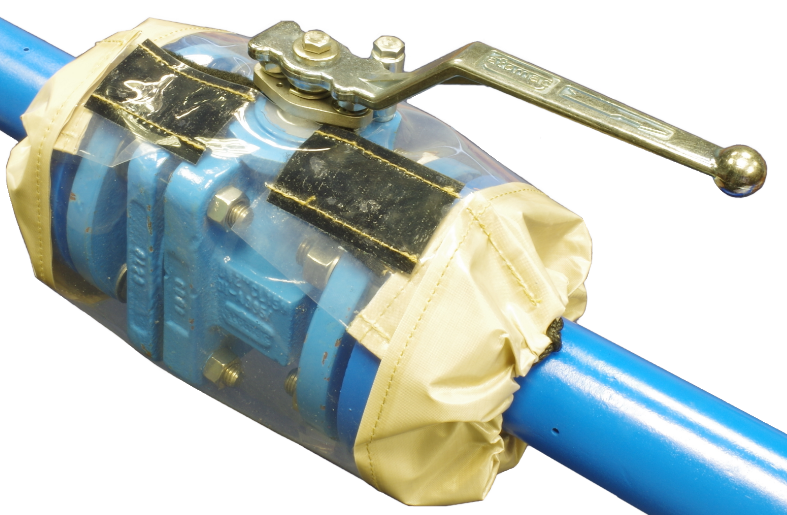

Elbow Fittings

Elbow fittings serve a simple yet vital function: changing the direction of pipe systems. Available in different angles, usually 45° and 90°, these fittings are indispensable in complex, straightforward pipe layouts. Their design allows for rerouting pipes around obstacles or guiding them in specific directions, which is essential in construction and maintenance.

Made from various materials, including stainless steel, copper, and PVC, elbow fittings cater to different environments and requirements. Their strength lies in flexibility and adaptability, offering solutions that accommodate structural needs while ensuring a secure and efficient pipeline system.

Your Ally in Industrial Durability

Choosing Corrosion Resistant Products Ltd. is more than choosing a supplier. It means partnering with experts. We understand the challenges of corrosive chemicals. We dedicate ourselves to finding innovative solutions. We offer corrosion-resistant solutions that last. Let’s address the challenges of corrosion together.