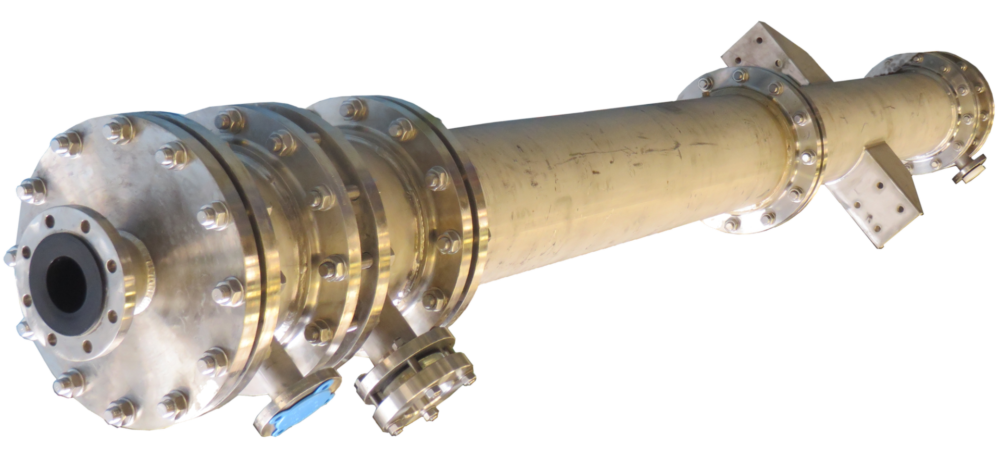

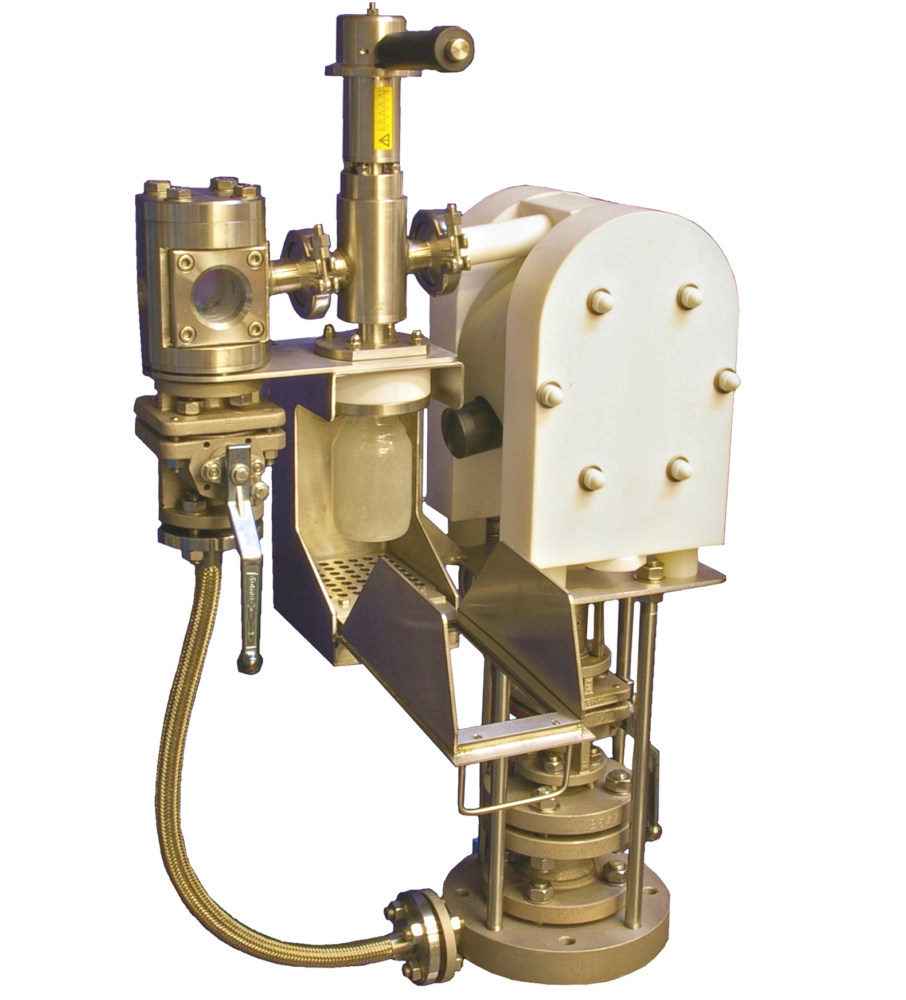

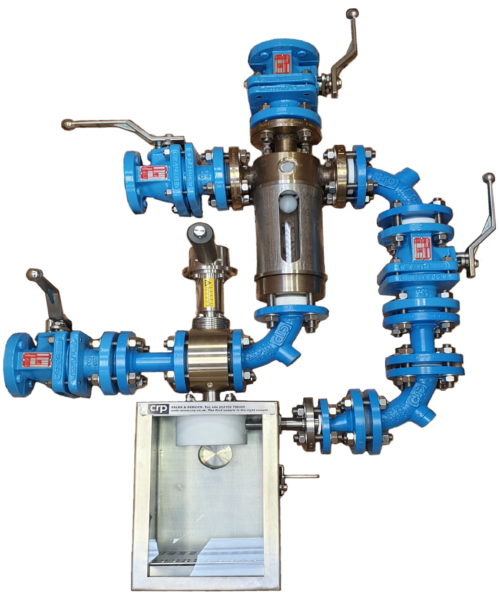

When a major pharmaceutical client in Scotland asked CRP if we could help with taking 1-inch branches from 1.5-inch static dissipating elbows in an installation with extremely limited space, we stepped up.

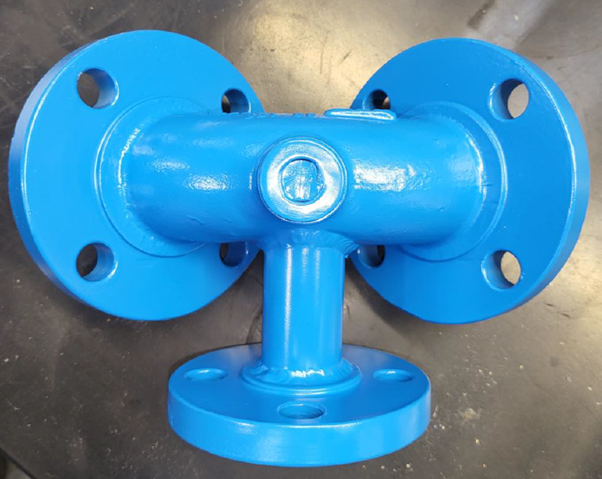

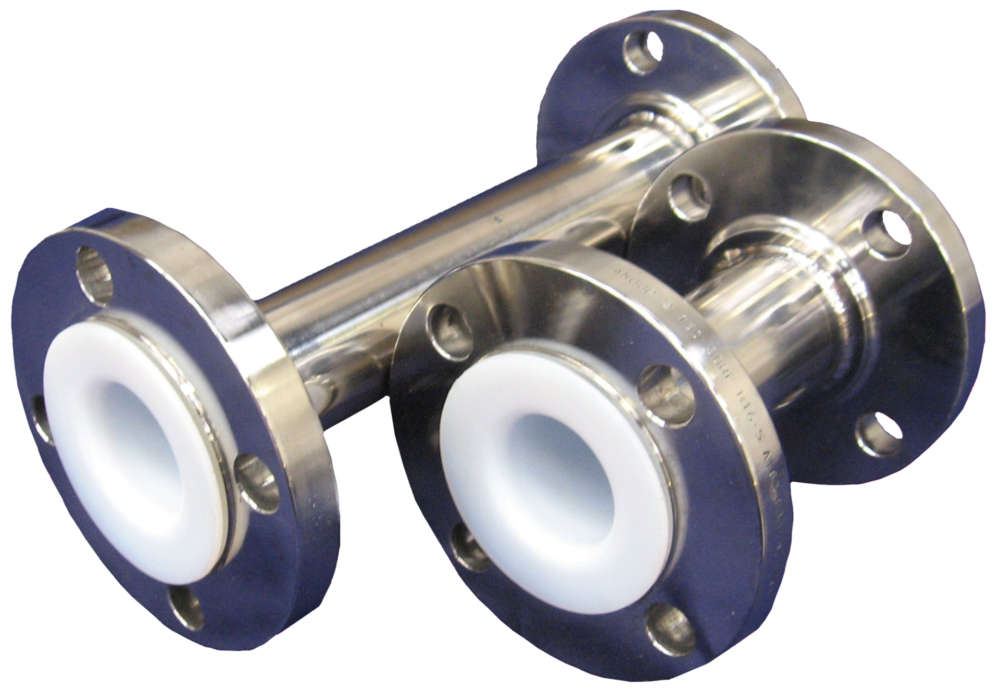

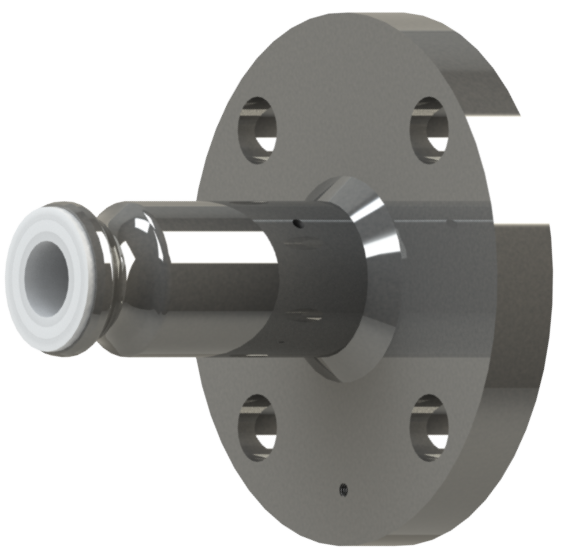

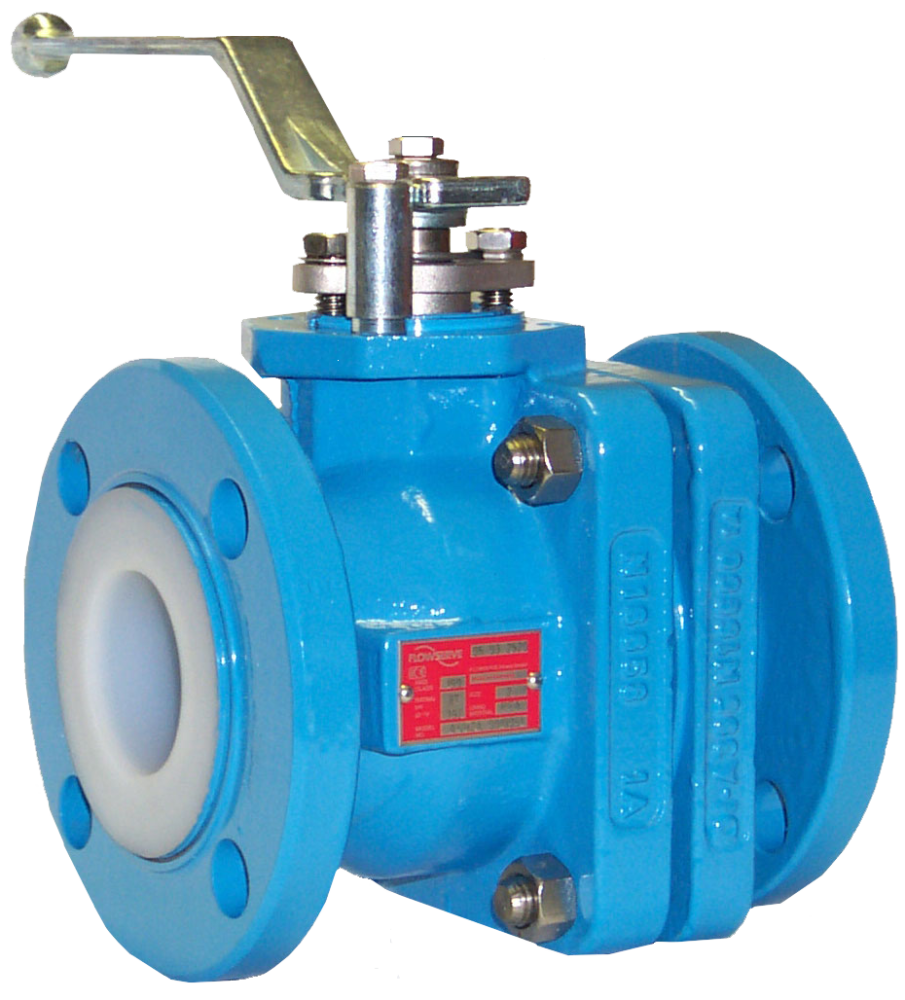

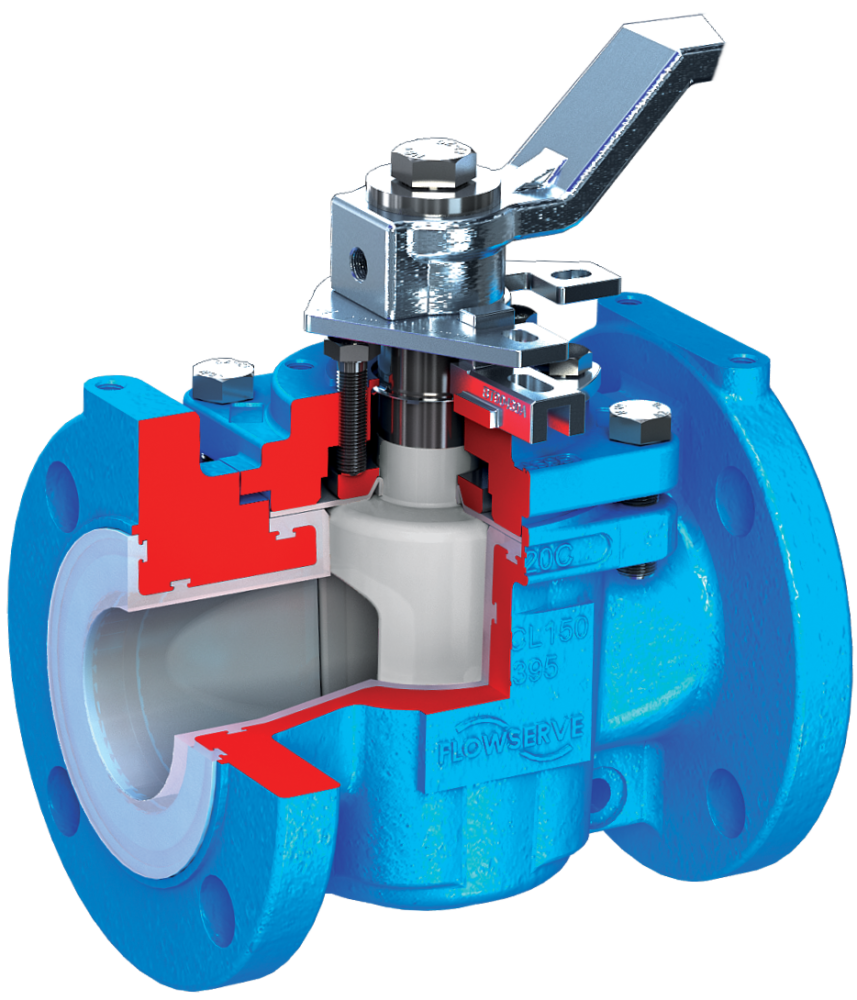

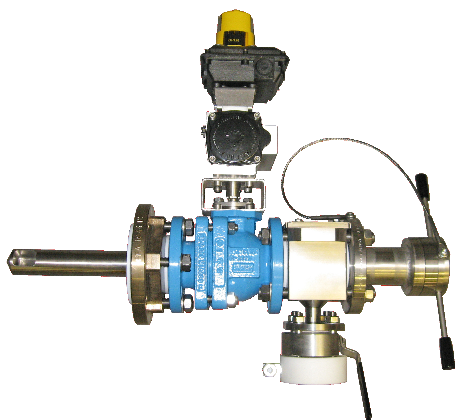

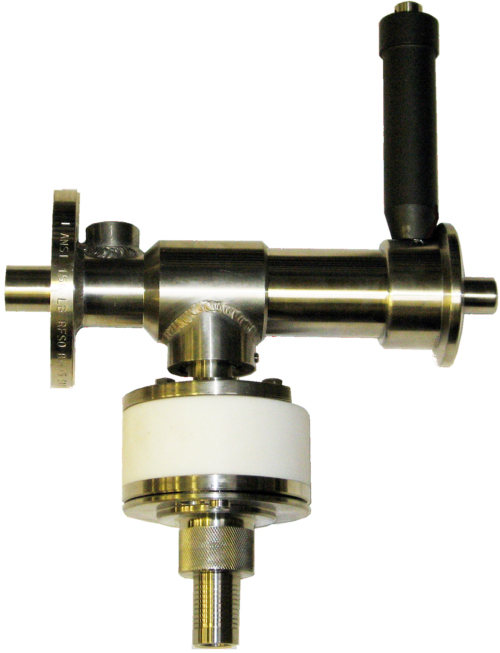

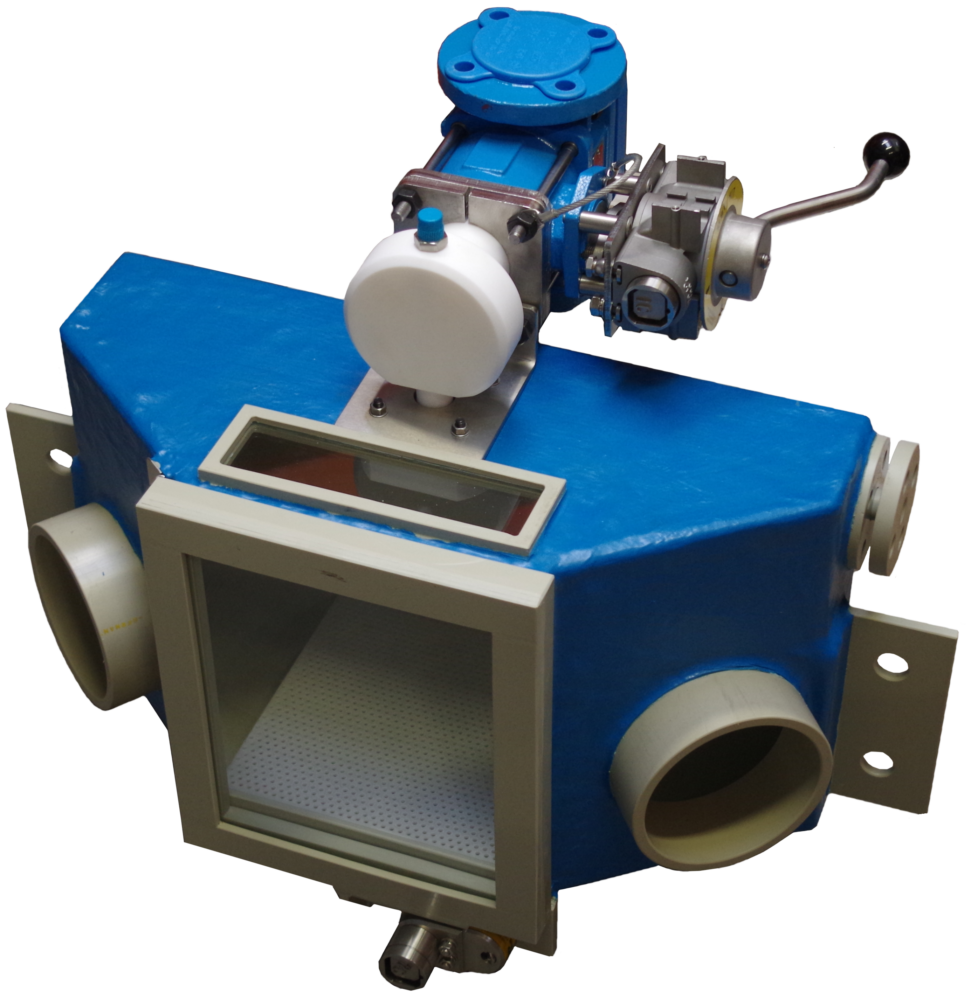

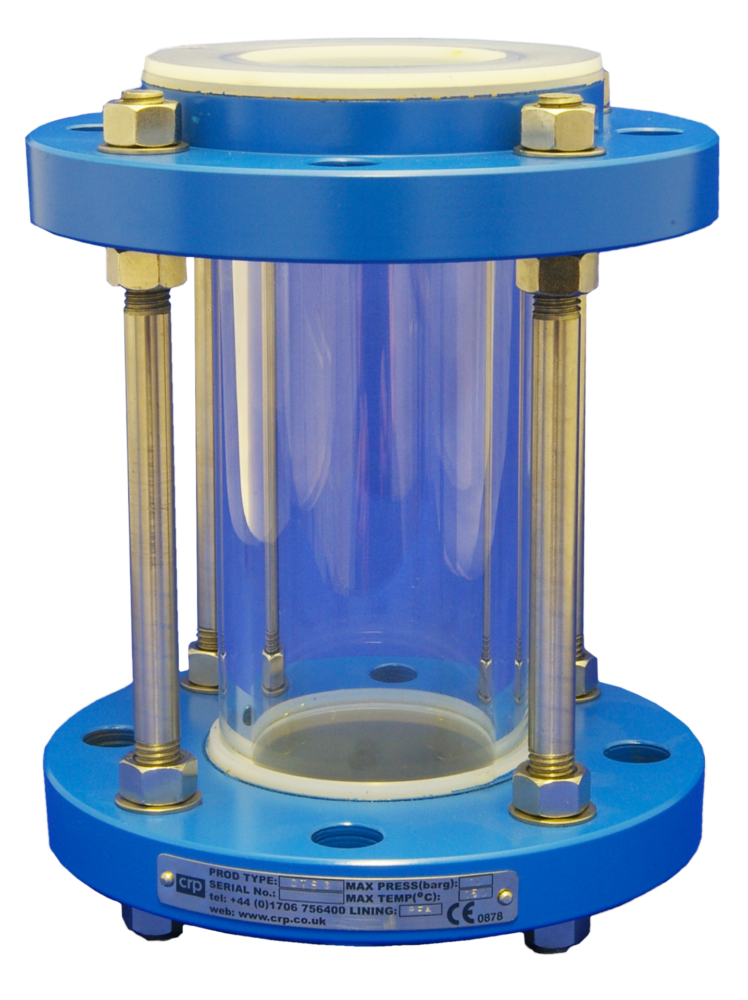

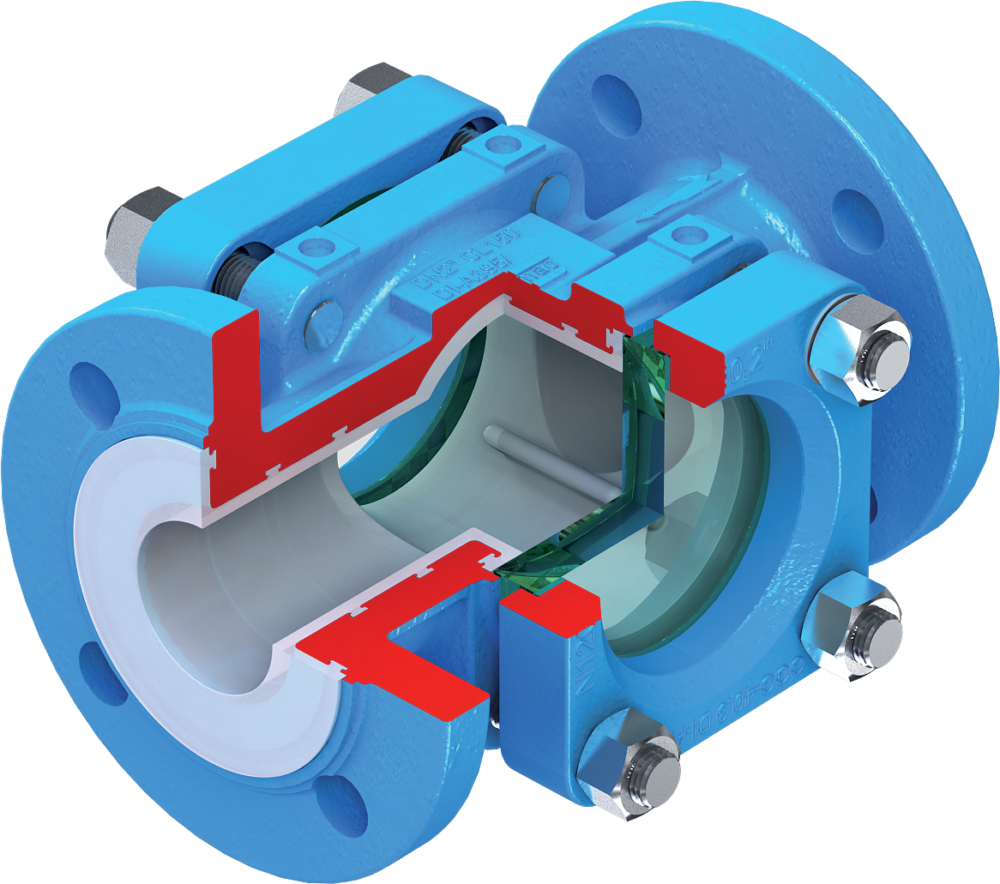

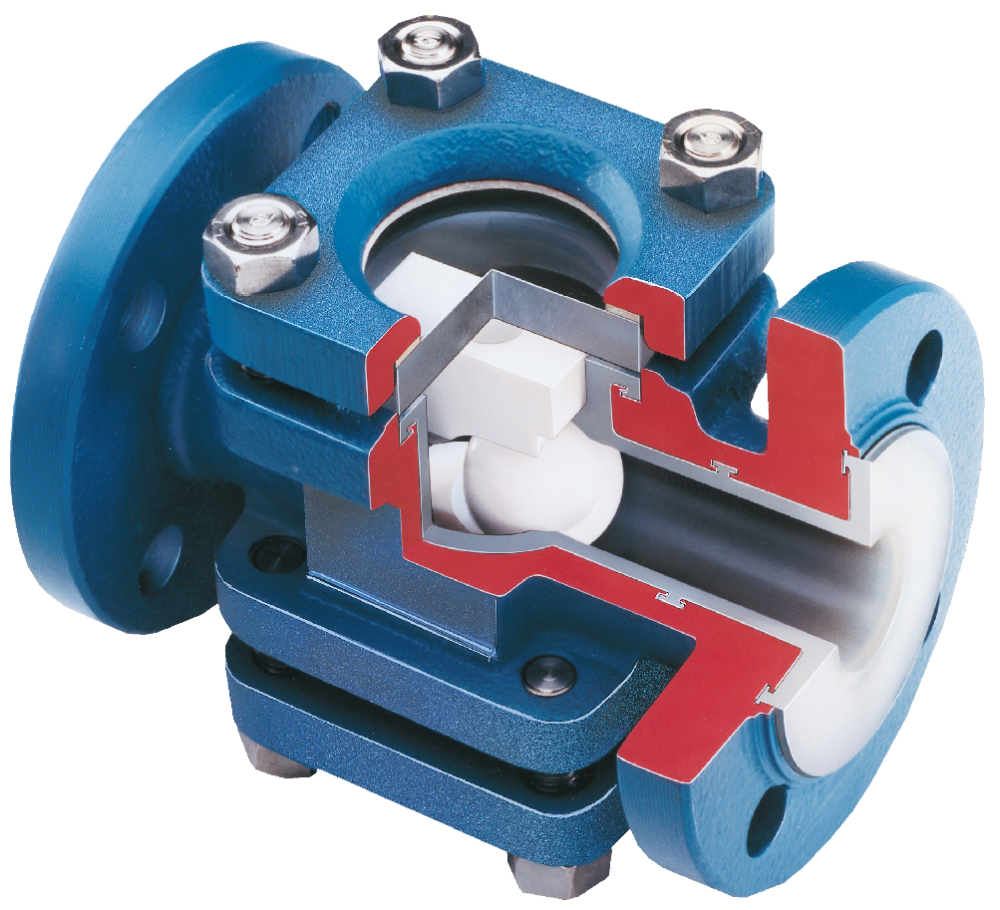

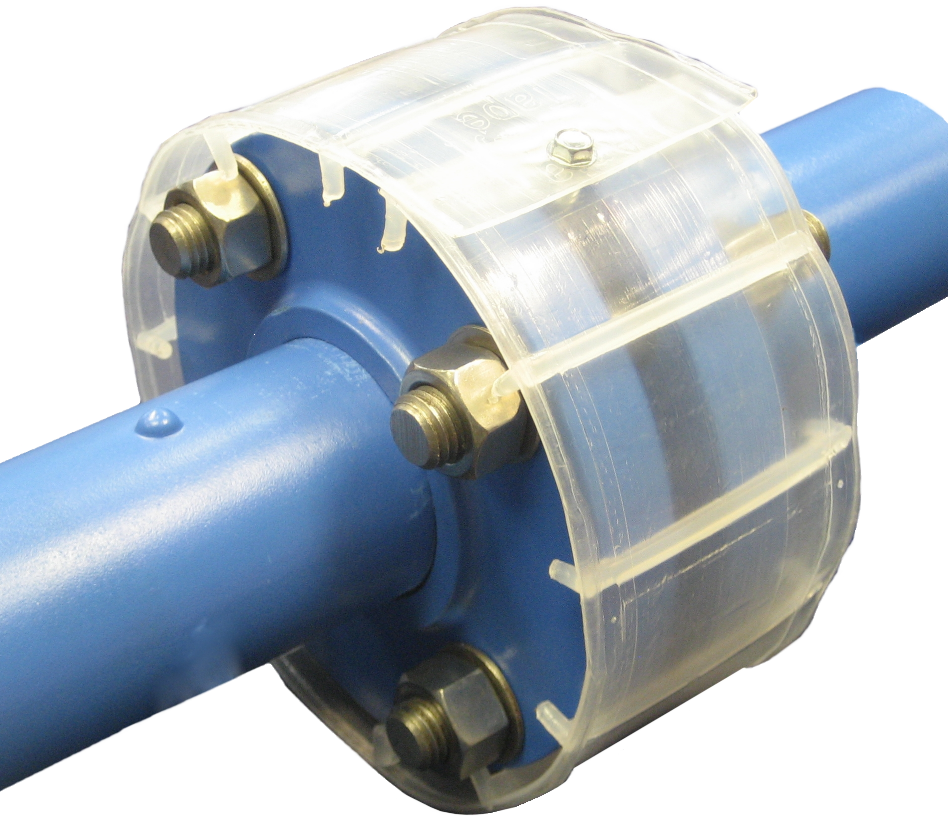

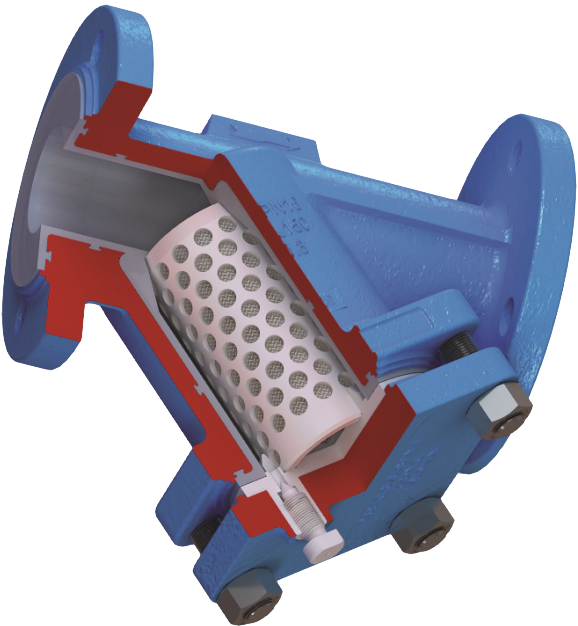

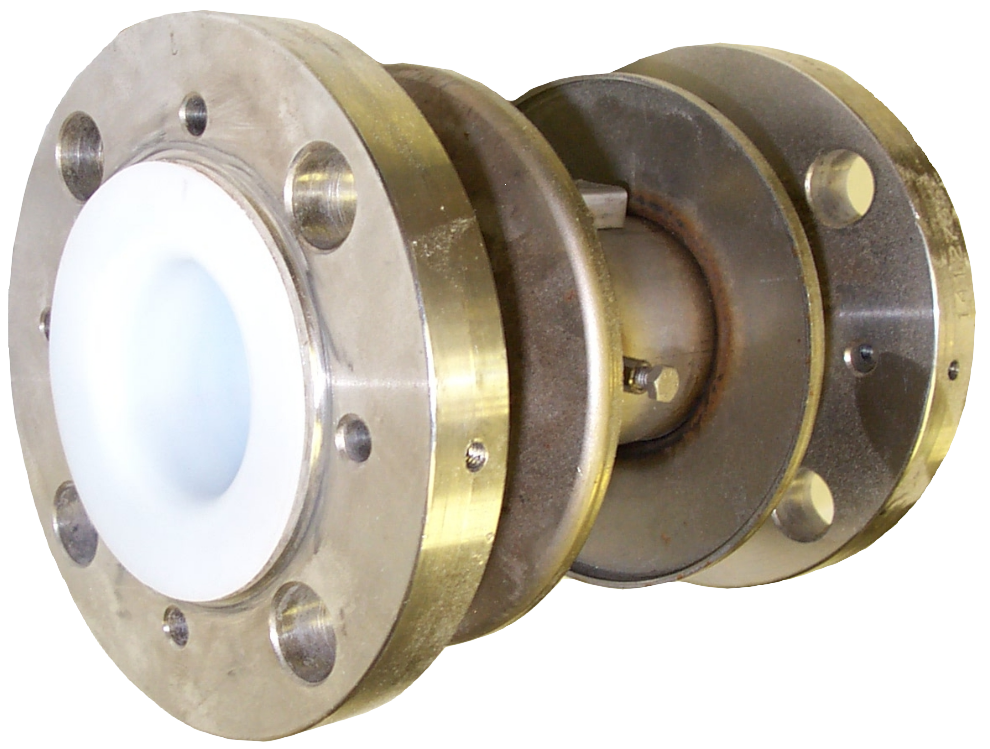

Alan Greenwood, Area Sales Manager for Scotland and the North East of England takes up the story; ‘The client required a number of elbows with reducing branches, set at 90 degrees to the centreline. These were to be installed in a very space restricted area of the plant where it was impossible to position a traditional Tee or even an instrument Tee. The need for the special elbows with branches was identified as part of a 3D modelling exercise by the contractor. In order to install new CRP equipment including sampling systems, valves, piping, and sight glasses on a small reactor, there would need to be a couple of special fittings. To add to the challenge, the elbows had to be PFA lined in static dissipating PFA, site standard at this safety conscious client.’

Following consultation with Steven Herbert, CRP’s manufacturing manager, it was agreed that this could be done fully in-house with our own coded welders. ‘Due to the bespoke nature of this challenge, we left the robot welding cell to continue with the spools and entrusted this work to a manually skilled welder instead,’ explains Steven.

The 1-inch reducing branch would be created using modified tooling and be PFA injected together with the main 1.5 inch bore as a one-piece component.

After moulding, the specials were hydrotested to 29 barg twice, to ensure their integrity before being stamped for conformity, painting, and final shipping to the incredibly happy client on time!