Design Fundamentals

Design Fundamentals

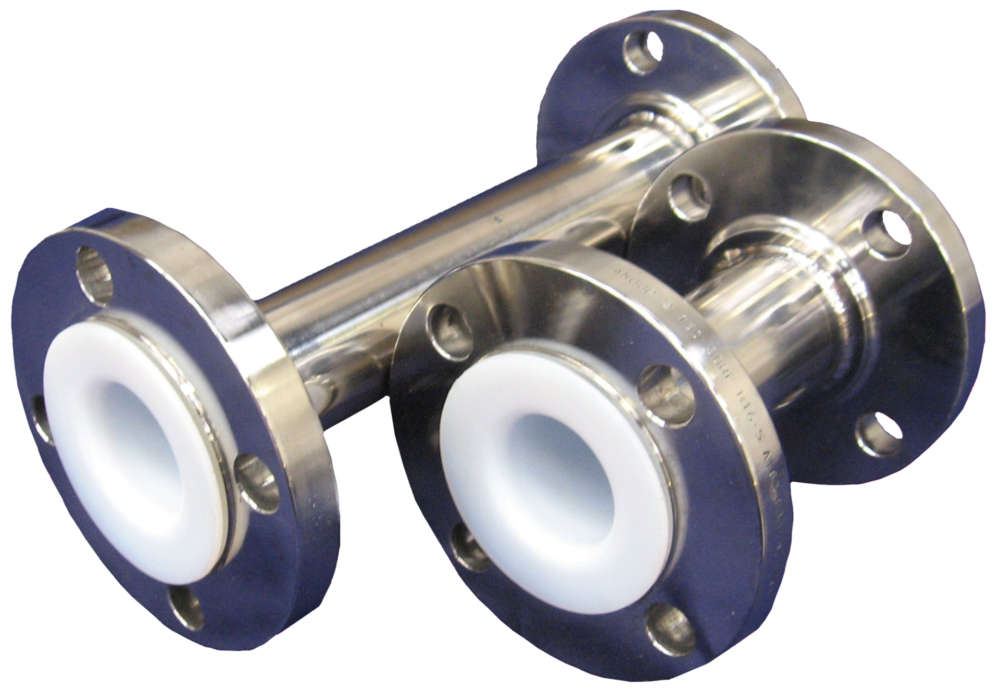

CRP are manufacturers of HiPerFlon PTFE and PFA lined piping for use in conveying extremely corrosive media like Nitric and Sulphuric acids. We only use modern designs and the latest fluoropolymers produced by well known International manufacturers in our lined piping systems.

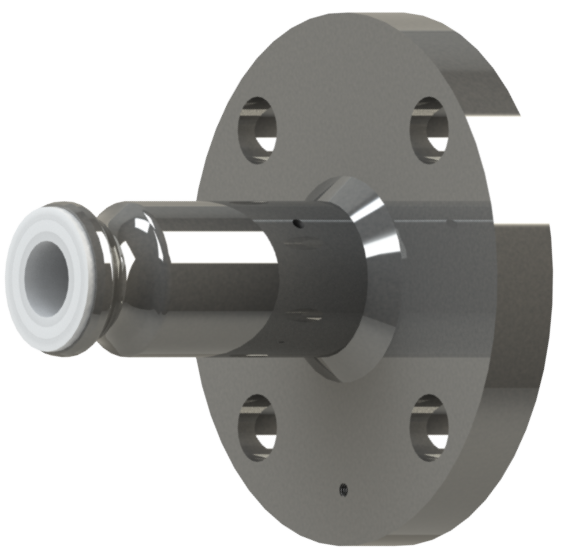

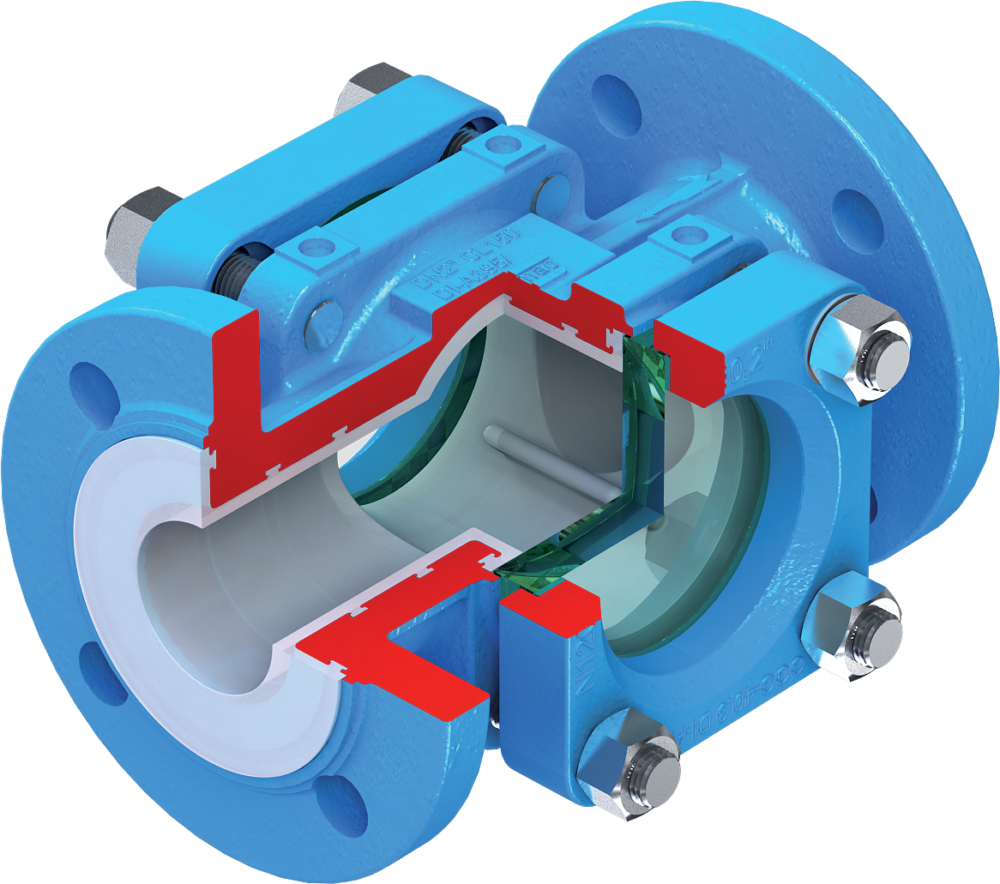

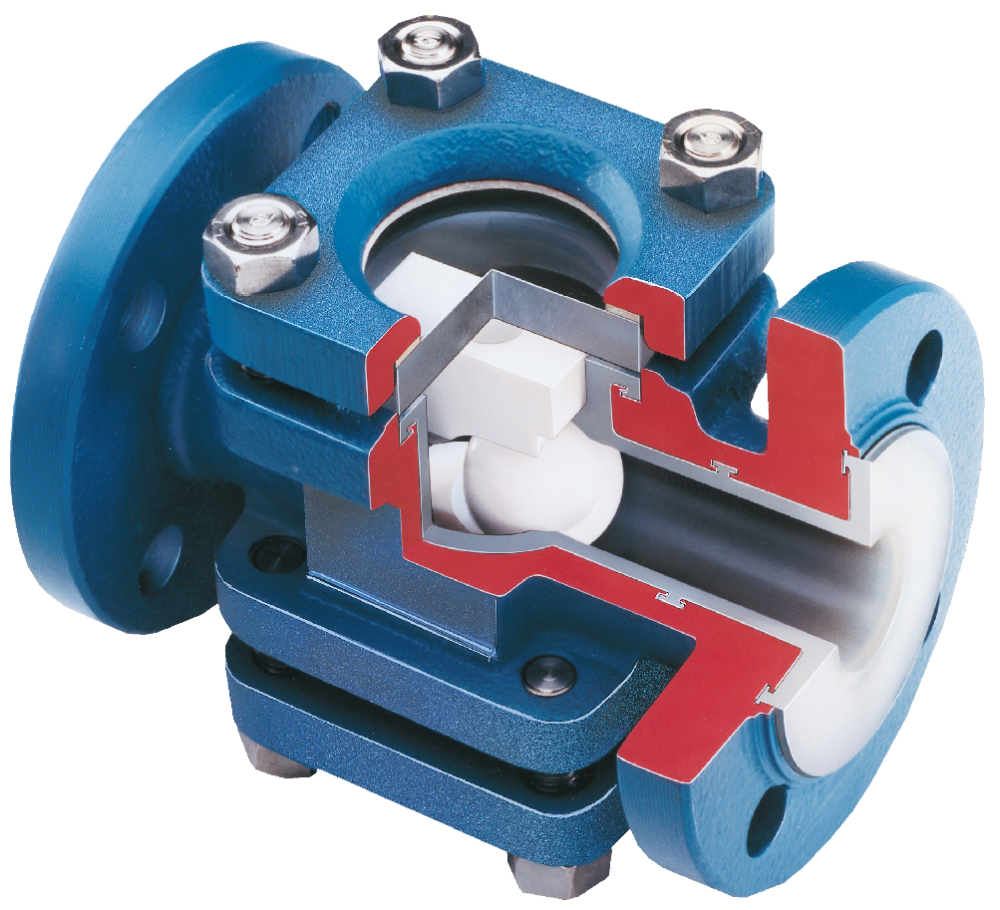

Our designs are focussed on achieving excellent corrosion resistance performance at elevated temperatures. The fluoropolymer materials we use also have properties such as non-stick, high purity and low-friction and although beneficial are secondary considerations. The core product range has been designed to sustain full vacuum as opposed to having a number of product standards. Our products use investment cast steel fittings as housings, as they provide great accuracy, high strength, are weld free, repeatable and a more aesthetically pleasing component.

Lining Materials

CRP only selects the best technologies for the lining processes. PTFE paste extrusion is used for straight pipe spools and simple shapes as it produces some of the best pipe liners for chemical performance, permeation resistance, wall accuracy and surface finish.

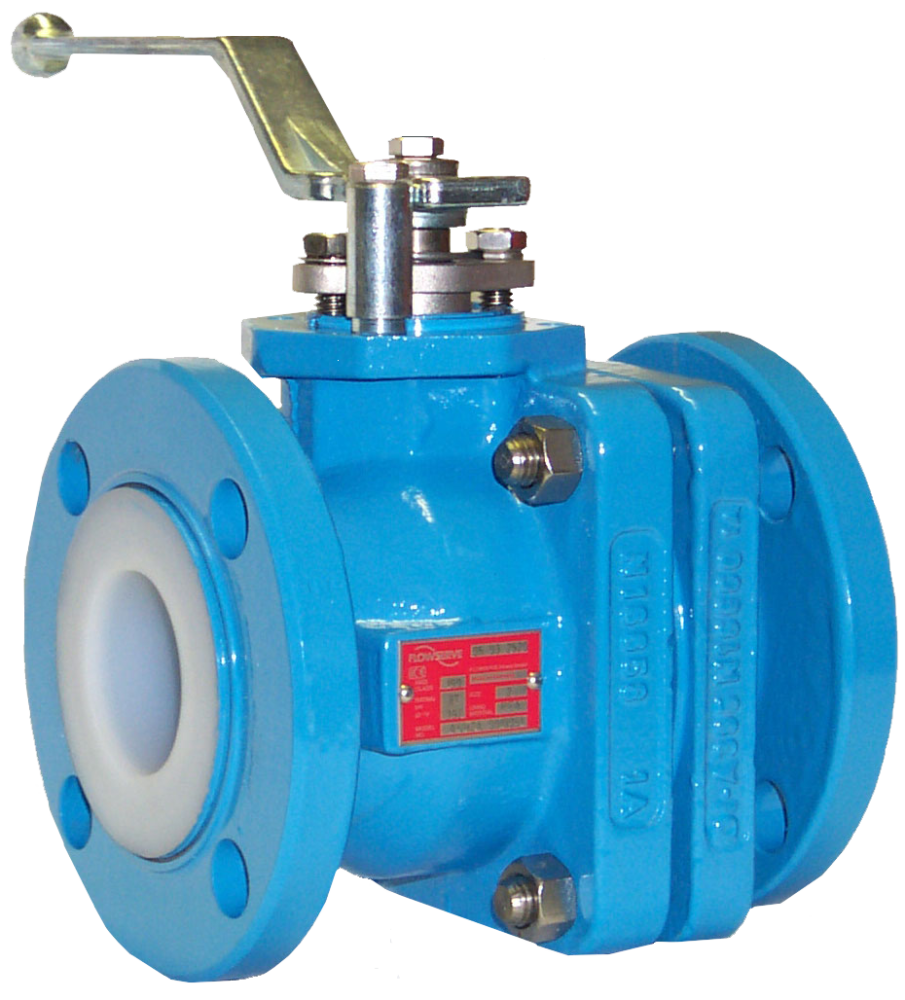

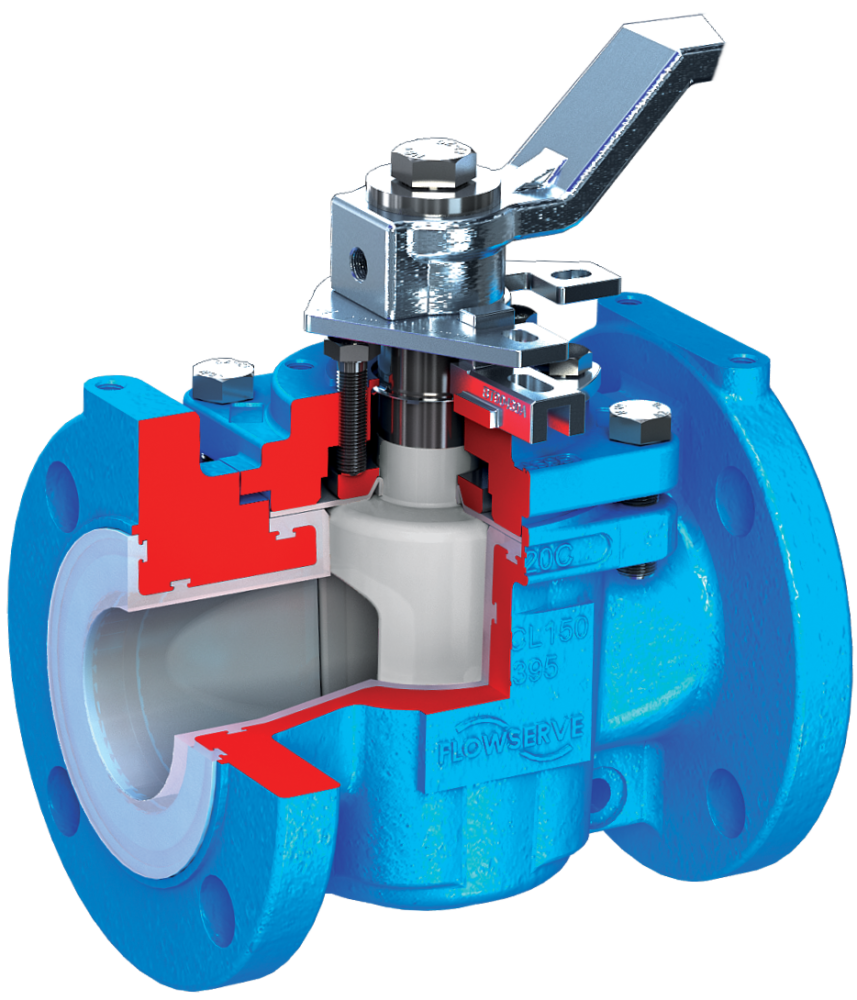

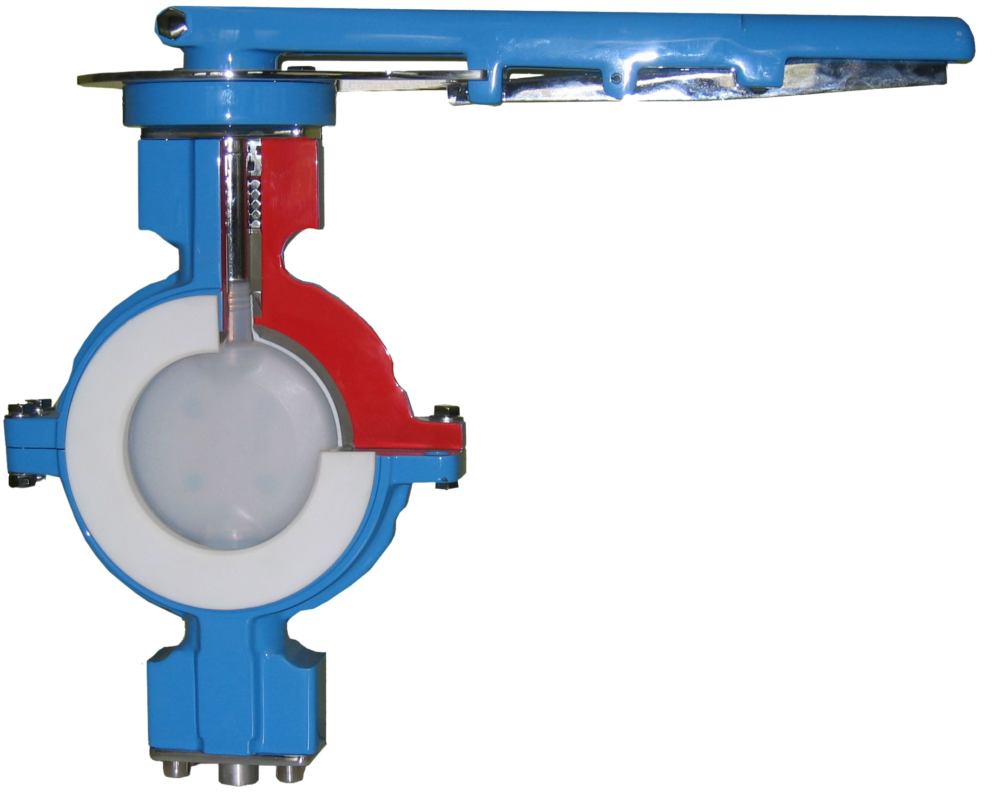

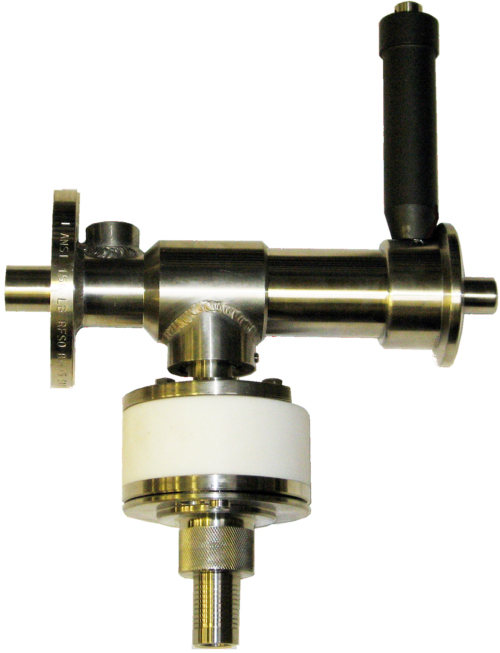

For more complex shapes like tees and valve bodies we employ PFA because it is melt processable to form and flow into these shapes, along with its translucency, surface finish, geometric accuracy and vacuum performance.

Moreover, CRP continues to invest production time in collaboration with major polymer producers to develop extrusion grades of PTFE and thermally stabilised grades of PFA.

The Lined Piping Specifications

The original CRP specification was a requirement to meet the ASTM standard F423. This has now been superseded by F1545. This is the basic design standard for PTFE lined pipe and fittings and apart from a restricted DIN standard and some national standards such as in Japan (JIS), it is the only worldwide standard for lined pipe and fittings.

CRP also meets the design standard for the then largest user in the UK – the ICI company. They had a piping standard considered to be more stringent than F423. This ICI standard – EDS.PIP.53.01c formed the basis for a great number of specifications around the UK.

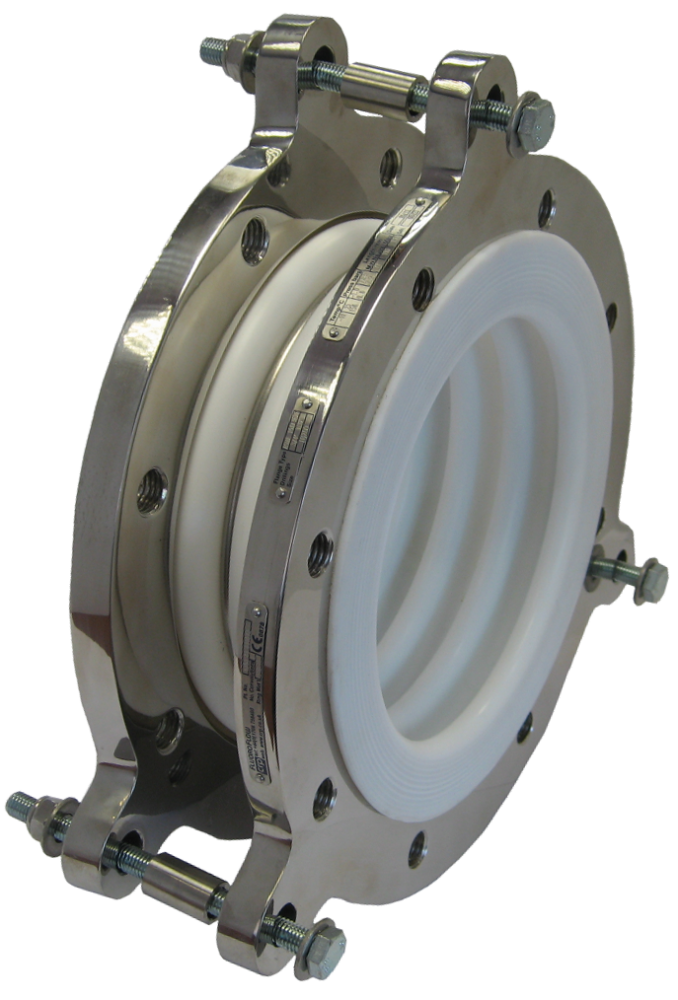

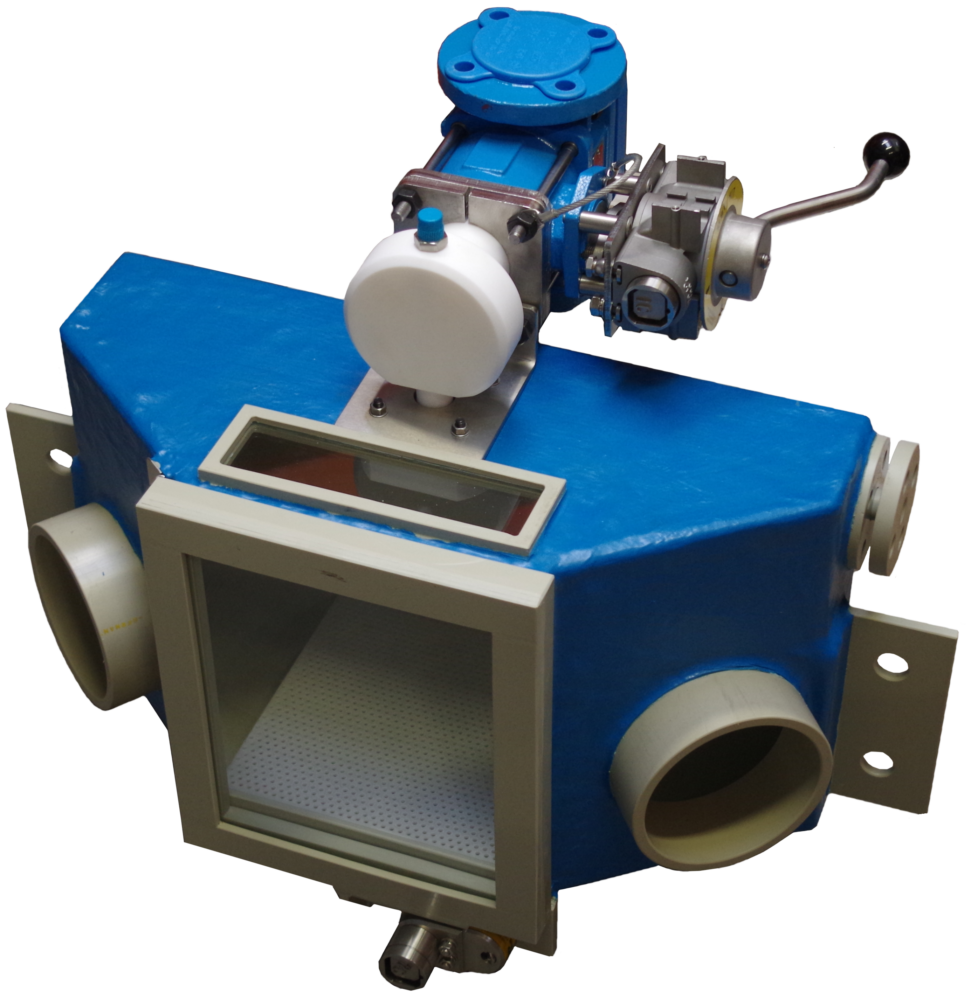

These design standards fixed the physical standards for the materials and determined how the housings should be made, their accuracy, the quality and performance of the liners and most importantly how the parts should be type tested and tested in manufacture. Type testing comprises subjecting representative production samples to extended periods of heating and cooling, steam cycling and vacuum resistance testing. CRP has conducted type testing to ASTM F423 on our lined piping and this has been witnessed and verified by an independent third party.

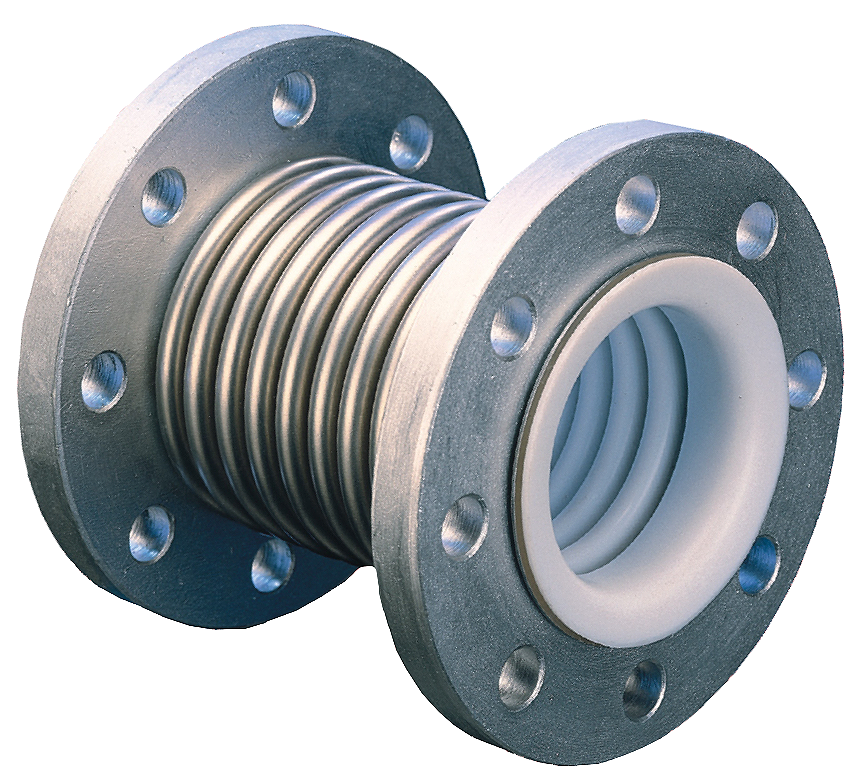

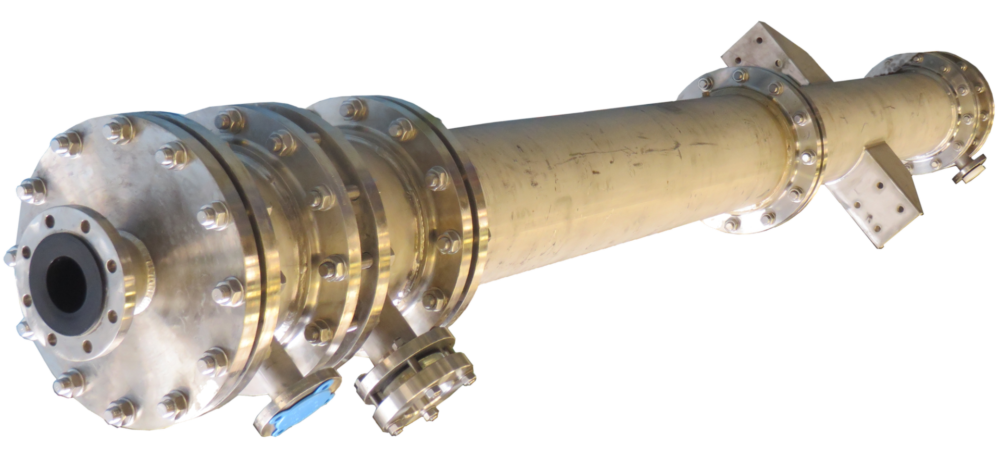

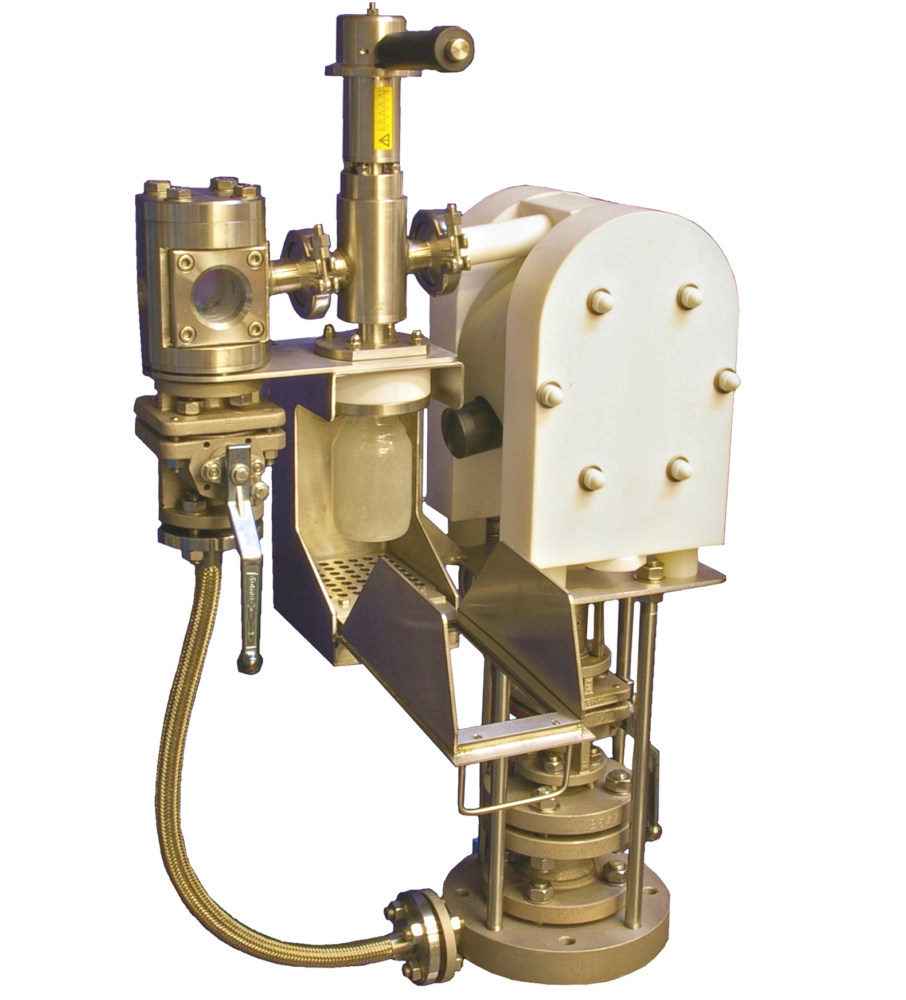

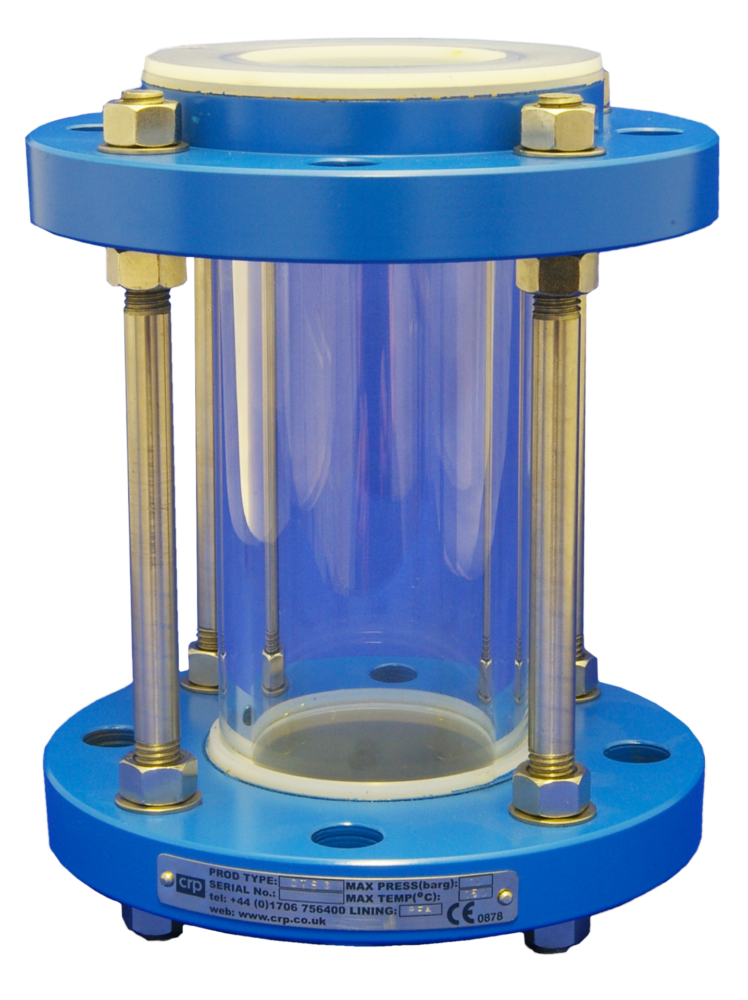

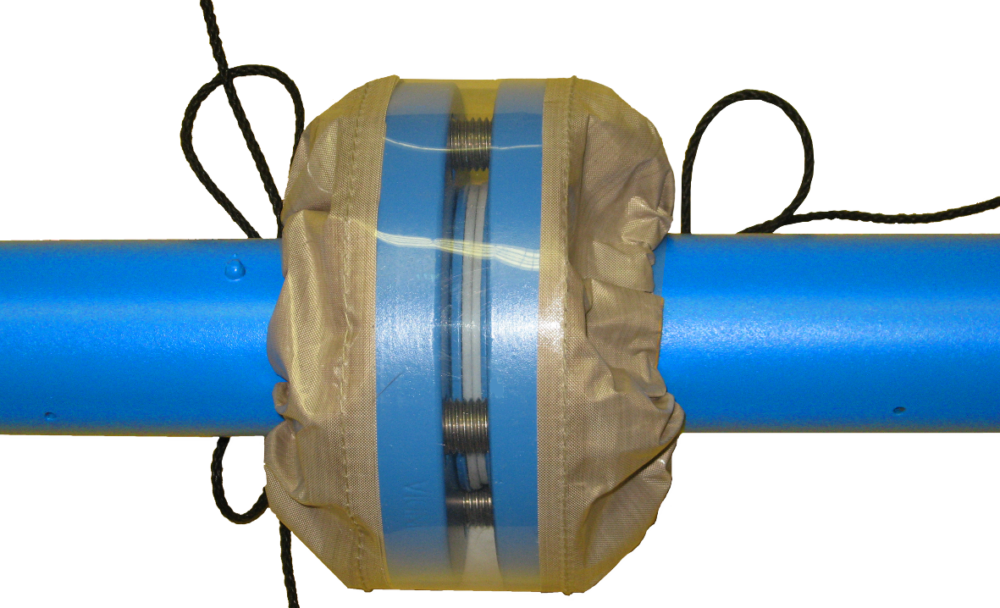

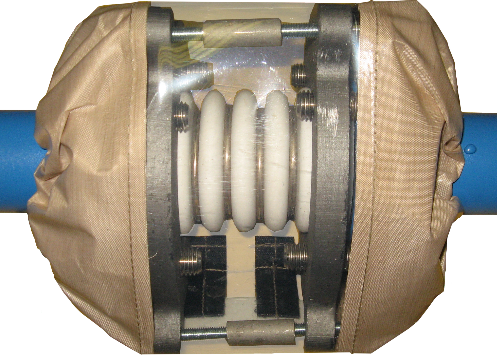

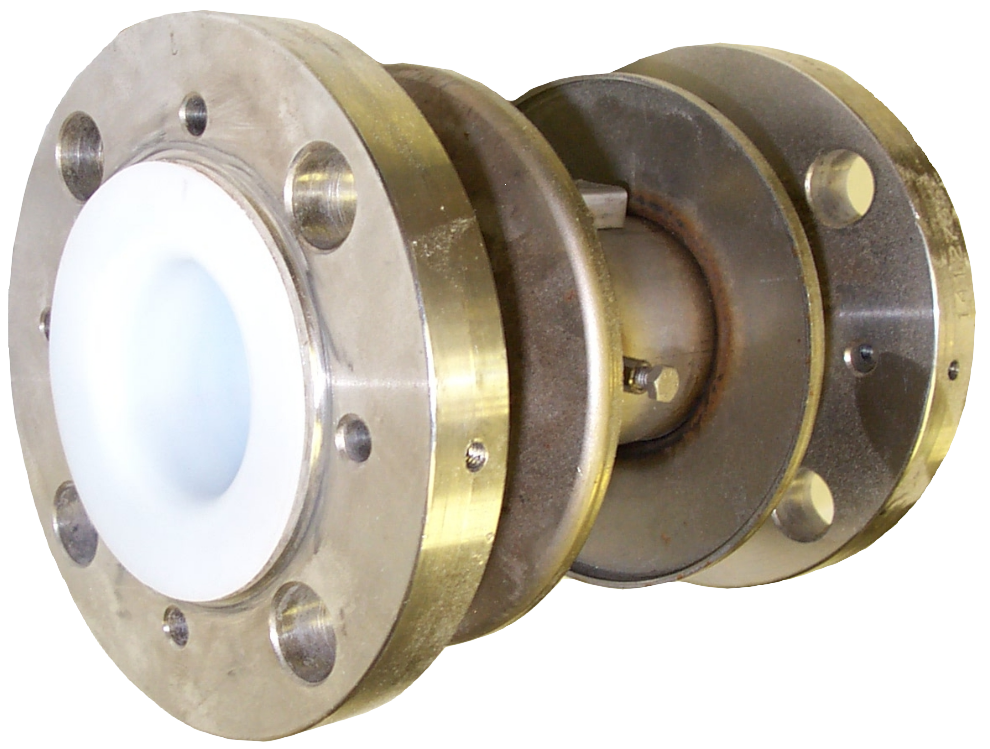

This is one of CRP’s test rigs undertaking steam cycling – alternate periods of steam at 9.5 bar(g) maintained for one hour and then rapid cold water flushing to return to ambient within two minutes. CRP undertook 500 cycles – the specifications only called for 100. To pass these tests the product must not show any detriment and still pass its production tests.

Pipework and Fittings

CRP decided to use the accepted design standards for pipework and fittings using ASME Class 150 flanges. Concerning the dimensional standard CRP uses ASME B16.5 Class 150 where there is a definition and for non defined products like instrument tees, we look to use the industry norms. We also produce pipe and fittings to DIN2874, dimensionally to DIN2848.

Materials

We work hard to ensure that the majority of our materials are suitable for food and drugs contact. The FDA (US Food and Drug Administration) are the recognised international body for deciding whether or not a material is suitable. As such CRP only uses FDA compliant materials as wetted parts. Only our static dissipating (anti-static) PFA materials are in exception to this as they are not FDA compliant, please note that static dissipating PTFE is FDA compliant.

There are a small number of fluoropolymer suppliers with well controlled materials that CRP uses. CRP evaluates all paste extrusion PTFE’s and melt processable PFA’s for approval. These materials must exceed the minimum requirements set out in ASTM F1545 – these being D4895 for paste polymers and D3307 for PFA.